A roasting defluorination device and process

A roasting and defluorination technology, applied in lepidolite fluidized bed roasting defluorination device and process field, can solve the problems affecting the normal operation of the rotary kiln process, unreasonable recovery and utilization of fluorine resources, and inability to use high-temperature tail gas energy, etc., to achieve Reduce corrosion and environmental pollution, promote migration and transformation, and improve defluorination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

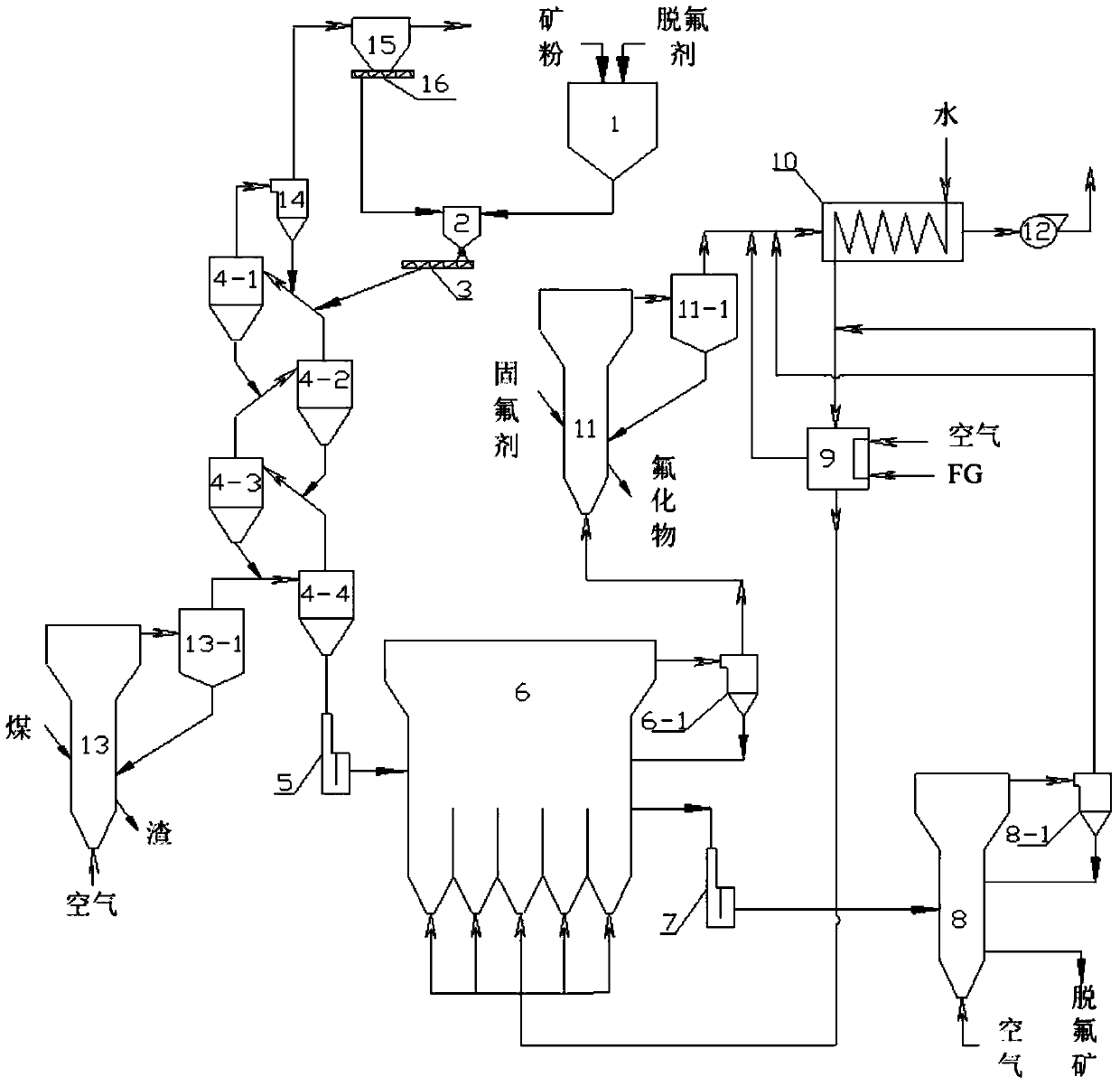

[0128] figure 1 Provides a schematic structural diagram of a lepidolite ore fluidized bed roasting defluorination device, the device includes: a material mixing system, a mixed material preheating system, a fluidized roasting system, a water vapor preheating system, a gas absorption system, and a cooling system and ventilation system.

[0129] The material mixing system is used to mix lepidolite ore powder and defluorinating agent and transport them to the mixed material preheating system, including mixing bin 1, hopper 2 and screw feeder 3;

[0130] The mixture preheating system is used to preheat the mixture of lepidolite powder and defluorinating agent to make the temperature reach 800-850°C, including coal-fired fluidized bed 13, coal-fired fluidized bed separator 13-1, four The first-stage cyclone preheater and cyclone separator 14, the four-stage cyclone preheater includes the first-stage cyclone preheater 4-1, the second-stage cyclone preheater 4-2, and the third-stage...

Embodiment 2

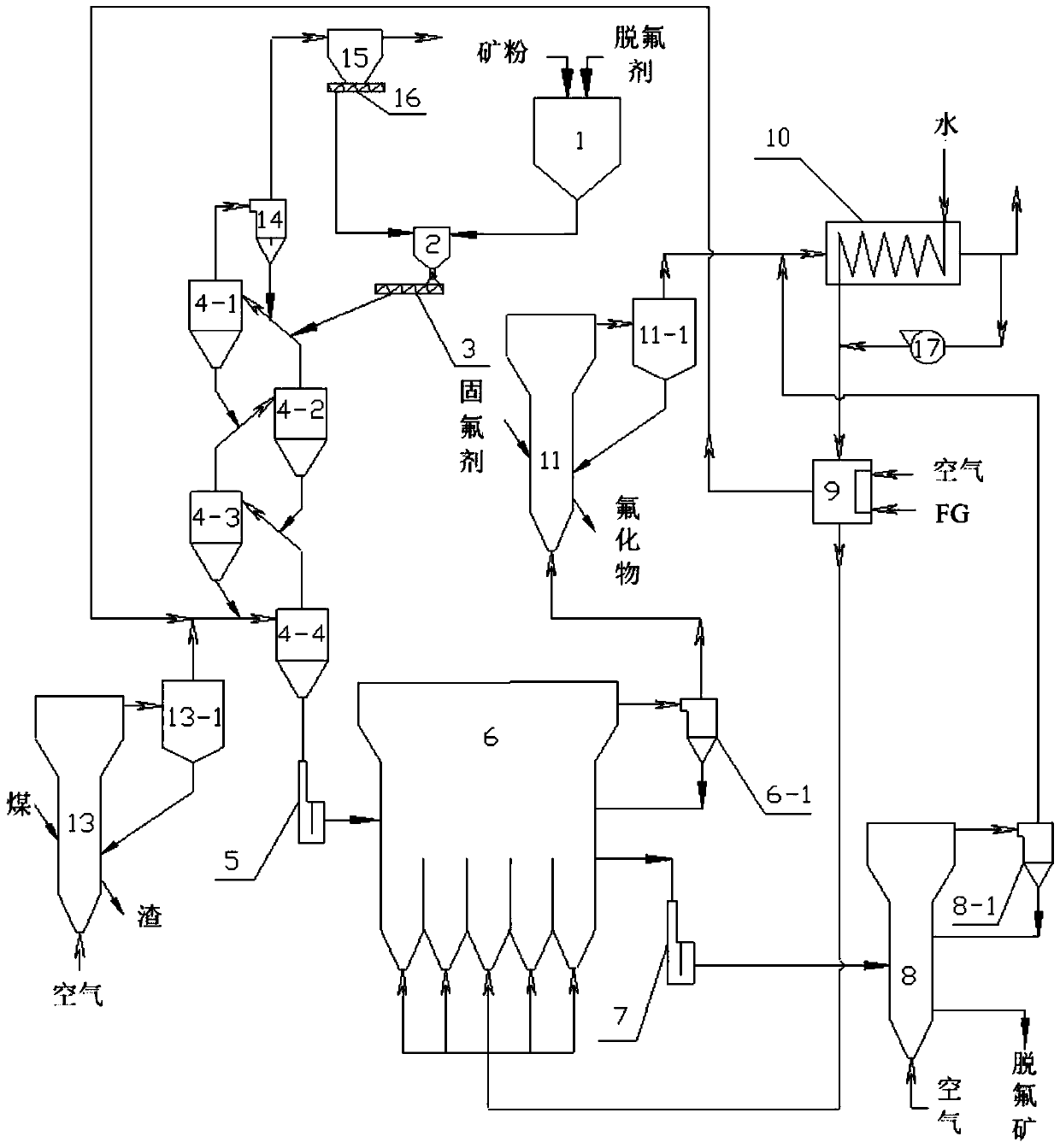

[0154] figure 2 Provides a schematic structural diagram of a lepidolite ore fluidized bed roasting defluorination device, the device includes: a material mixing system, a mixed material preheating system, a fluidized roasting system, a water vapor preheating system, a gas absorption system, and a cooling system and ventilation system.

[0155] The material mixing system is used to mix lepidolite ore powder and defluorinating agent and transport them to the mixed material preheating system, including mixing bin 1, hopper 2 and screw feeder 3;

[0156] The mixture preheating system is used to preheat the mixture of lepidolite powder and defluorinating agent to reach a temperature of 800-850°C, including coal-fired fluidized bed 13, coal-fired fluidized bed separator 13-1, four-stage Cyclone preheater and cyclone separator 14, the four-stage cyclone preheater includes the first-stage cyclone preheater 4-1, the second-stage cyclone preheater 4-2, and the third-stage cyclone preh...

Embodiment 3

[0179] Utilize the device that embodiment 1 provides to carry out lepidolite roasting defluorination, comprise the steps:

[0180] (1) Fully mix lepidolite ore powder and defluorinating agent in the mixing chamber 1, then send them into the hopper 2, send them to the fourth-stage cyclone preheater 4-4 through the screw feeder 3, and pass through the third stage in turn The cyclone preheater 4-3, the second-stage cyclone preheater 4-2 and the first-stage cyclone preheater 4-1 exchange heat with the high-temperature hot flue gas from the coal-fired fluidized bed 13; at the same time, The steam boiler 10 and the combustion chamber 9 produce high-temperature steam;

[0181] (2) The temperature of the preheated lepidolite ore powder and defluorinating agent rises to 800°C, and they are sent to the fluidized bed roaster 6, and fully contact with the high-temperature water vapor (900°C) from the combustion chamber 9 for roasting and defluorination. The fluorine reaction changes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com