A method for catalytically improving the defluorination efficiency of wet-process phosphoric acid stripping

A wet-process phosphoric acid and defluorination technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problems of defluorination efficiency and yield impact, improve defluorination efficiency, reduce defluorination cost, and improve phosphoric acid quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

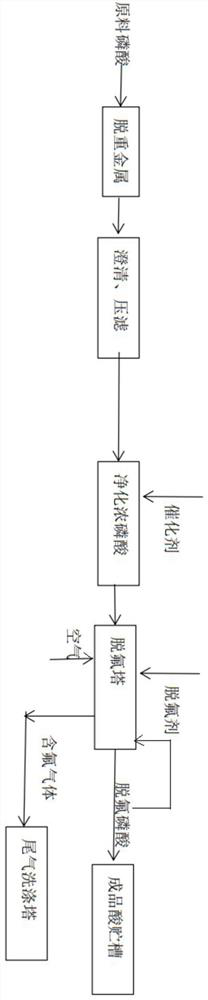

Image

Examples

Embodiment 1

[0035] A 100,000-ton / year feed-grade phosphoric acid plant in a phosphoric acid plant uses a tower-type air blowing deep defluorination process to purify phosphoric acid. Firstly, the raw material phosphoric acid is treated with arsenide removal and heavy metal removal, and then it is clarified and filtered to obtain P 2 o 5 The mass concentration is 41%P 2 o 5 , F content of 0.5%, solid content of 0.4% clarified concentrated phosphoric acid.

[0036] Add 80m of purified concentrated phosphoric acid from the clear acid collection tank to the connecting tank of the defluorination tower 3 , the amount of catalyst added is 3.8m 3 , the catalyst is EDTA, the mass concentration is 5%; the defluorination agent is 5.7m 3 , the defluorinating agent is white carbon black, and the mass concentration of the defluorinating agent is 9%. After mixing evenly, it is heated by steam, and the phosphoric acid is heated to 90°C and then sent to the defluorination tower for circulating spray...

Embodiment 2

[0040] A 100,000-ton / year feed-grade phosphoric acid plant in a phosphoric acid plant uses a tower-type air blowing deep defluorination process to purify phosphoric acid. Firstly, the raw material phosphoric acid is treated with arsenide removal and heavy metal removal, and then it is clarified and filtered to obtain P 2 o 5 The mass concentration is 43.28%P 2 o 5 , F content of 0.82%, solid content of 0.71% clarified concentrated phosphoric acid.

[0041] Add 80m of purified concentrated phosphoric acid from the clear acid collection tank to the connecting tank of the defluorination tower 3 , the amount of catalyst added is 1.6m 3 , the catalyst is malonic acid, the mass concentration is 12%; the defluorination agent is 7.6m 3 , the defluorination agent is active SiO 2 , the mass concentration of the defluorinating agent is 11%. After mixing evenly, heat it with steam, heat the phosphoric acid to 105°C and send it to the defluorination tower for internal circulation sp...

Embodiment 3

[0045] A 100,000-ton / year feed-grade phosphoric acid plant in a phosphoric acid plant uses a tower-type air blowing deep defluorination process to purify phosphoric acid. Firstly, the raw material phosphoric acid is treated with arsenide removal and heavy metal removal, and then it is clarified and filtered to obtain P 2 o 5 The mass concentration is 46.5%P 2 o 5 , F content of 0.9%, solid content of 1.0% clarified concentrated phosphoric acid.

[0046] Add 80m of purified concentrated phosphoric acid from the clear acid collection tank to the connecting tank of the defluorination tower 3 , the amount of catalyst added is 2.7m 3 , the catalyst is citric acid, the mass concentration is 7%; the defluorination agent is 7.1m 3 , the defluorinating agent is diatomite, and the mass concentration of the defluorinating agent is 13%. After mixing evenly, heat the phosphoric acid with steam to 110°C and send it to the defluorination tower for circulating spraying, with a circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com