A load-type defluorination agent for removing hydrogen fluoride in hydrogen chloride gas and its preparation method

A hydrogen chloride gas, load-type technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of decreased fluorine removal efficiency, limited fluorine removal efficiency, cumbersome process, etc., and increase the effective contact area , excellent defluorination efficiency and capacity, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

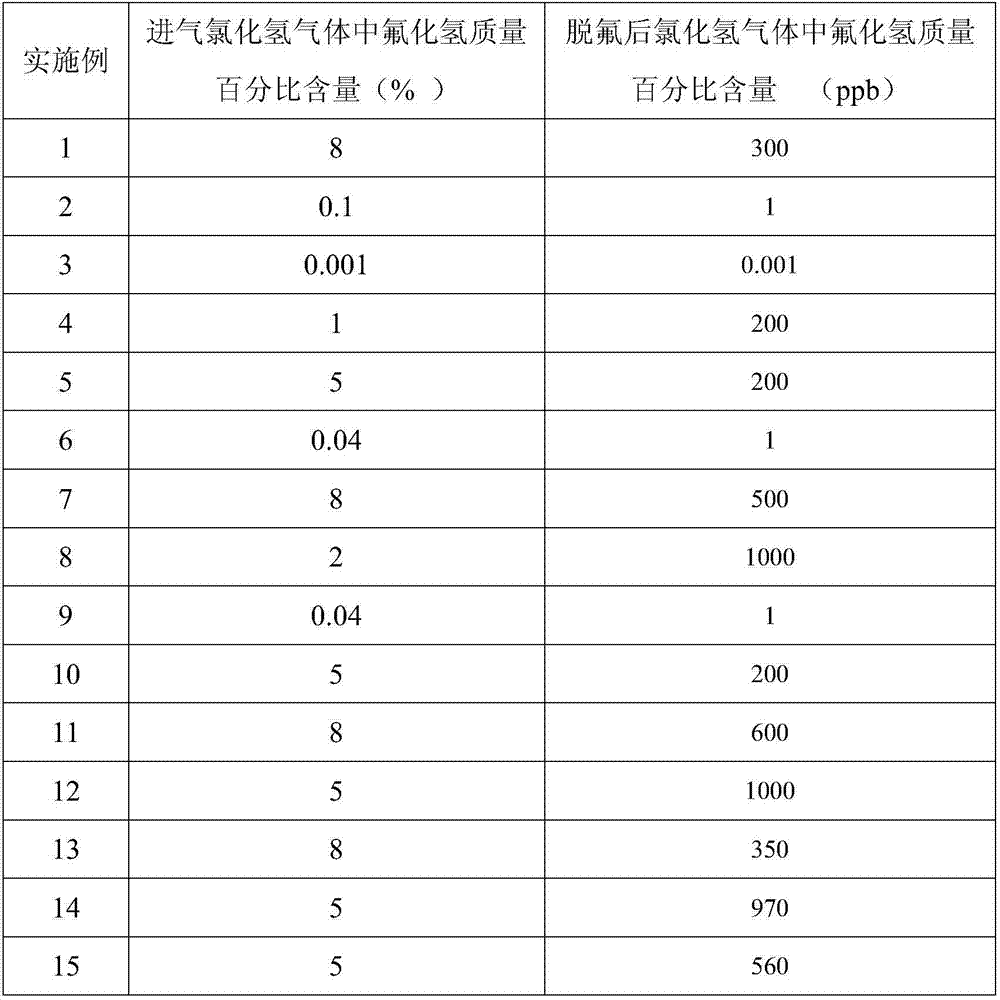

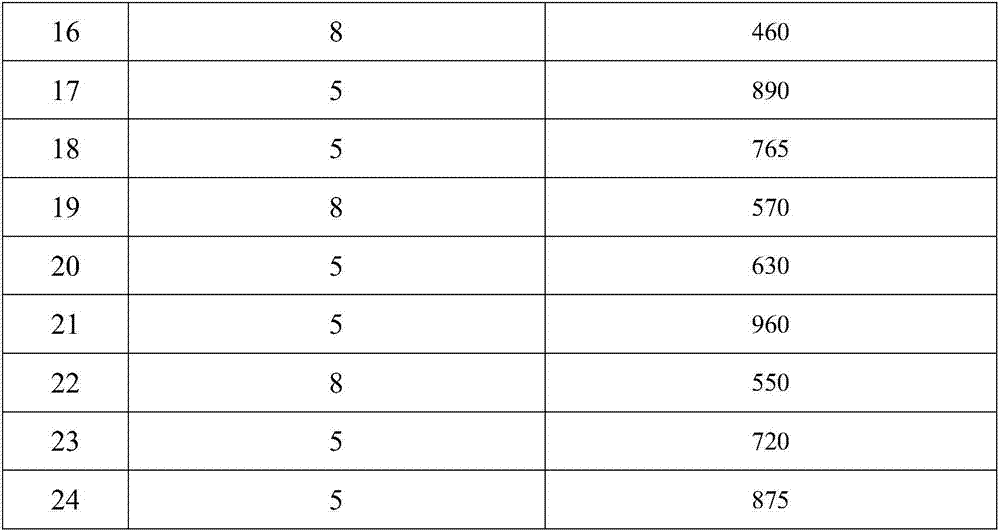

Examples

Embodiment 1

[0034] Take activated carbon particles (the average diameter of activated carbon particles is 0.005mm, and the average specific surface area is 3000m 2 / g) 100g and be immersed in the calcium chloride solution that 500g mass percent concentration is 60%, after solution is absorbed completely, obtain the gac granule of impregnated treatment; The gac granule of impregnated treatment is dried at 200 ℃ respectively, Vacuum dehydration at 400°C for 1 hour each to obtain loaded highly dispersed anhydrous calcium chloride, which exists in the form of particles with a diameter of 0.1nm-5μm and a thin layer with a thickness of 0.1nm-5μm inside and outside the pores of activated carbon.

Embodiment 2

[0036] Take activated carbon particles (the average diameter of activated carbon particles is 1mm, and the average specific surface area is 1600m 2 / g) 100g and impregnated in 250g mass percentage concentration is in the calcium chloride solution of 40%, after solution is absorbed completely, obtains the gac granule of impregnation treatment; The gac granule of impregnation process is dried at 90 ℃ respectively, Vacuum dehydration at 300°C for 24 hours each to obtain loaded highly dispersed anhydrous calcium chloride, which exists in the form of particles with a diameter of 0.1nm-5μm and a thin layer with a thickness of 0.1nm-5μm inside and outside the pores of activated carbon.

Embodiment 3

[0038] Take activated carbon particles (the average diameter of activated carbon particles is 2mm, and the average specific surface area is 200m 2 / g) 100g and be immersed in 150g mass percent concentration and be in the calcium chloride solution of 20%, after solution is absorbed completely, obtain the gac granule of impregnated treatment; The gac granule of impregnated treatment is dried at 25 ℃ respectively, Vacuum dehydration at 150°C for 48 hours each to obtain loaded highly dispersed anhydrous calcium chloride, which exists in the form of particles with a diameter of 0.1nm-5μm and a thin layer with a thickness of 0.1nm-5μm inside and outside the pores of activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com