Sulfate pulping method of broadleaf wood compressed wood chip

A kraft, hardwood technology, applied in the field of pulping and papermaking, can solve problems such as high cost and low efficiency, and achieve the effects of reducing transportation and storage space, easy stacking and stacking, and beneficial to pulping energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

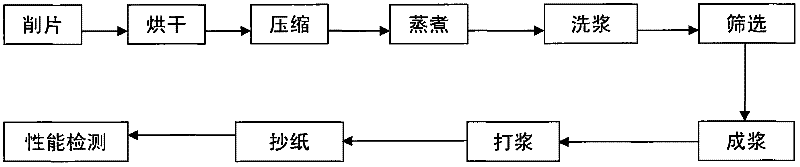

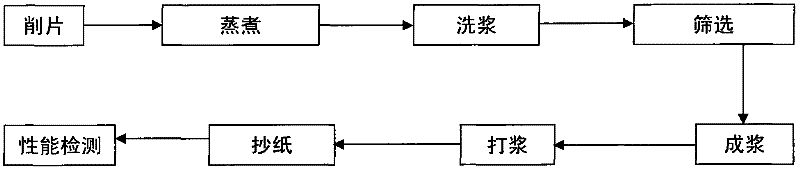

Method used

Image

Examples

Embodiment 1

[0021] The technical conditions for drying and compressing eucalyptus wood chips: take eucalyptus wood chips, dry them at 105°C until the moisture content is 15%, and then dry them at 300kg / cm 2 The eucalyptus wood chips were compressed into cuboid blocks of 15cm x 7.5cm x 6cm under a certain pressure.

[0022] Get compressed and uncompressed eucalyptus wood chips 2kg (dry) respectively and carry out kraft pulping under the following process conditions: total alkali 16% (calculated as NaOH), sulfidation degree 25%, maximum temperature 170 ℃, heat preservation 100min, heat up 120min, liquid ratio 1:4.5.

[0023] The two pulps were screened with a 0.25mm slotted sieve, and then beaten with a PFI beater with a beating concentration of 10% and a target beating degree of 44°SR.

[0024] Pulping and papermaking weight is 60g / m 2 , Pulp properties are tested in accordance with the paper industry standard method.

[0025] Table 1 shows the comparison of the pulping properties of co...

Embodiment 2

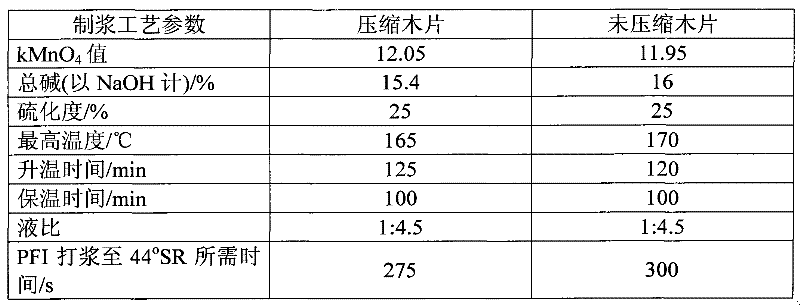

[0030] Under the premise of achieving the same pulping hardness, the pulping process parameters of compressed eucalyptus wood chips and uncompressed wood chips are shown in Table 2.

[0031] Table 2

[0032]

[0033] As can be seen from Table 2, when reaching the same slurry kMnO 4 Compared with uncompressed wood chips, the total alkali consumption of compressed eucalyptus wood chips was reduced by 0.6 percentage points, the maximum cooking temperature was lowered by 5°C, the heating time was prolonged by 5 minutes, and the cooking conditions were milder. The required time was reduced by 8.33%, indicating that pulping chemicals and energy consumption can be reduced by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com