Combined lumber and fabrication technique thereof

A manufacturing process and wood square technology, which is applied in the field of encrypted modified wood and its manufacturing process, can solve the problems of insufficient glue strength, low hardness, and seldom used, etc., and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

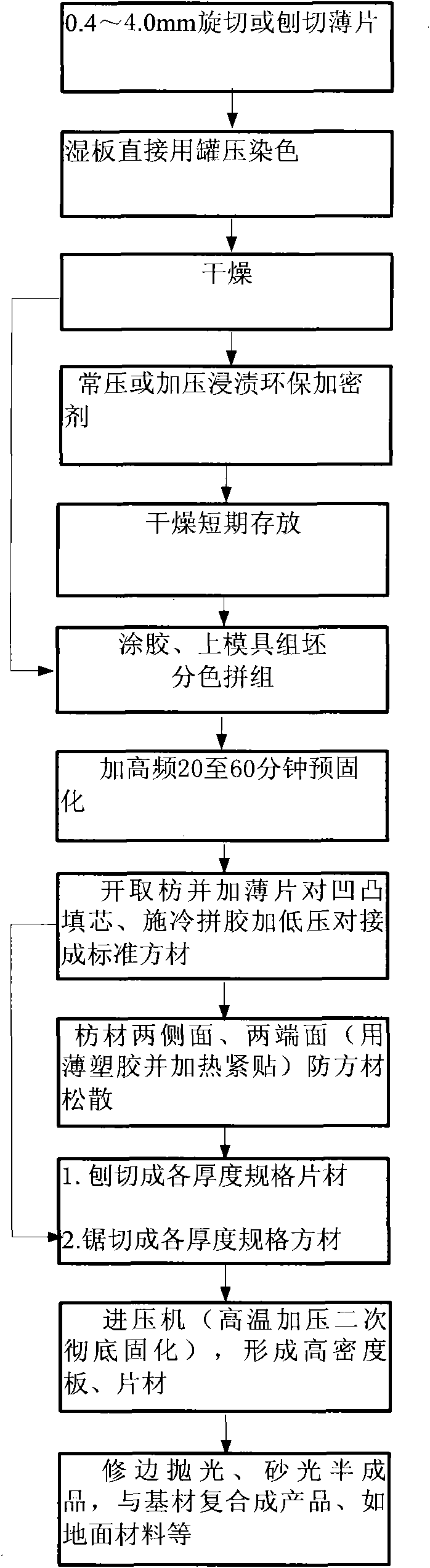

Method used

Image

Examples

example 1

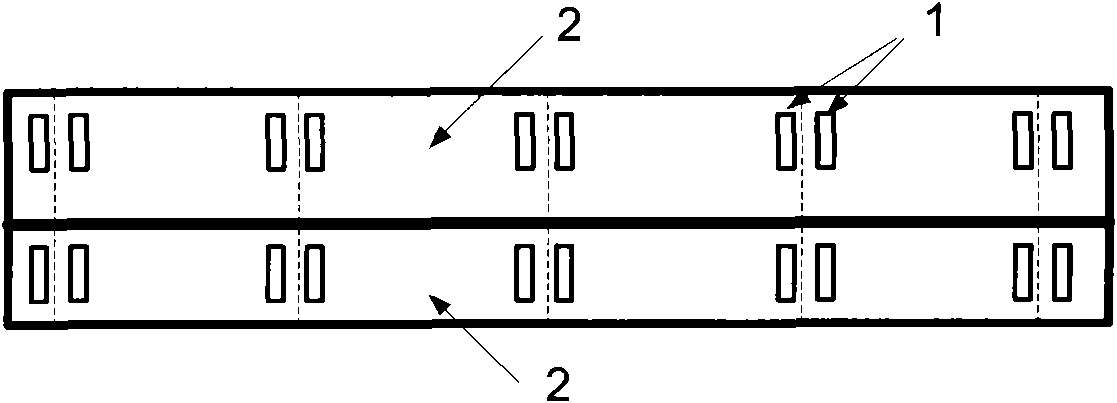

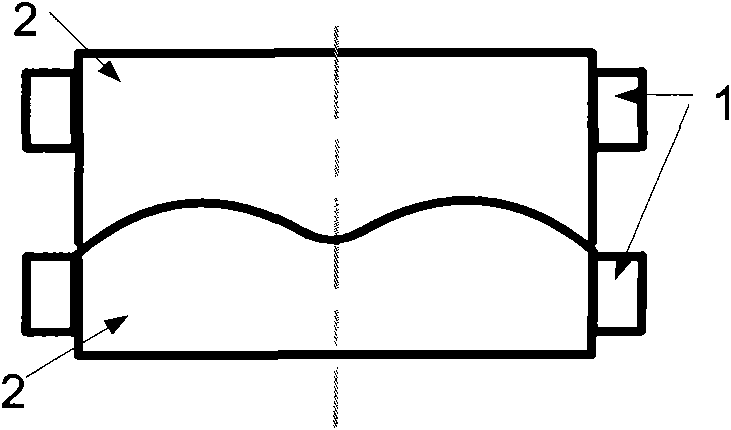

[0048] Example 1: use Guangdong artificial fast-growing eucalyptus, its density is 0.5g / cm 3 , using this process to rotary cut wood chips with a thickness of 1.2 mm, a width of 360 mm, and a length of 2500 mm, put the wood chips into a pressurized dyeing tank, and then suck in the pre-heated dyeing solution by vacuum, heat and start the cycle to make the solution uniform, at 105 ° C , pressure 0.4Mp, hold for 60 minutes to stop dyeing, cool down and relieve pressure, take it out, use a drum dryer to dry to a moisture content below 12%, and then apply phenolic resin glue on one side, the glue amount is 160 grams per square meter, and then place it on the Assemble the billets on the double-arc mold, and use wood chips of different colors to produce color patterns. In this example, two sheets of natural color and one red, two sheets of natural color and one blue, and two sheets of natural color and one green. Each sheet must be aligned on one side and combined into When the heig...

example 2

[0049] Example 2: Its density is 0.45g / cm with artificial fast-growing lotus 3 , using this process to rotary cut wood chips with a thickness of 0.8mm, a width of 360mm, and a length of 2500mm, put the wood chips into a pressurized dyeing tank, keep the pressure at 103°C and 0.3Mp, and stop dyeing after 60 minutes, take it out after cooling down and releasing the pressure, and use a drum to dry Machine dried until the moisture content is below 12%, then put it into a pressure tank for encryption. In this example, phenolic resin is used as the encryption agent. The tank press equipment adopts a pressure tank with the function of flexing the solvent. Keep Mp for 90 minutes to release the pressure and take it out. When the wood chip is taken out after impregnation, use the tubular discharge hole 6 compressed air to blow off the surface glue on both sides of the wood chip. Figure 4 In the process, the surface glue blown out flows back into the tank or tank to reduce waste and fac...

example 3

[0050] Example 3: with artificial fast-growing forest poplar, its density is 0.3g / cm 3 , using this process to rotary cut wood chips with a thickness of 1.5mm, a width of 360mm, and a length of 2500mm, put the wood chips into a pressurized dyeing tank, keep the pressure at 101°C and the pressure of 0.35Mp, and stop dyeing after 60 minutes, take it out after cooling down and releasing the pressure, and use a drum to dry Machine dried to less than 12% moisture content and put into pressure tank for encryption. In this example, phenolic resin is used as the encryption agent. The tank press equipment adopts a pressure tank with the function of flexing the solvent. (Similar to the dyeing pressure vessel) first vacuumize and then inhale for encryption Then pressurize to 0.8Mp and keep it for 60 minutes to release the pressure and take it out. After the impregnation is finished, use the tubular row of compressed air to blow off the surface glue on both sides of the wood chips (such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com