Method for producing white gypsum being by-product of wet process phosphoric acid

A technology of wet-process phosphoric acid and white gypsum, which is applied in phosphoric acid, phosphorus oxyacids, calcium/strontium/barium sulfate, etc., can solve problems such as consumption and large sulfur resources, reduce environmental pollution, reduce production costs, and improve value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

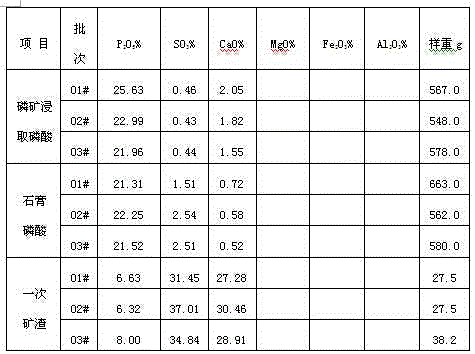

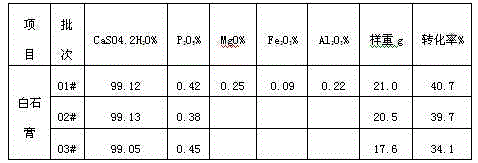

[0018] Take P 2 o 5 Add 400g of 20wt% wet-process phosphoric acid and 200g of dry mineral powder into a 1000ml beaker at the same time, and stir at 350r / min for 2h at 80°C. Stop stirring and let stand for 10 minutes, filter the gypsum slag, dry and weigh the gypsum slag. Add 37g of 98wt% concentrated sulfuric acid to the filtered clear liquid, stir for 10 minutes, let stand for 40 minutes, filter the white phosphogypsum, dry and weigh the white phosphogypsum. The filtrate phosphoric acid was weighed for detection. The parameters of wet-process phosphoric acid and mineral powder are shown in Table 1, and the result data are shown in Table 2 and Table 3:

[0019] Table 1

[0020] Table 2

[0021]

[0022] table 3

[0023]

[0024] It can be seen from the above data that: wet-process phosphoric acid and mineral powder are fed at a ratio of 2:1, the average conv...

Embodiment 2

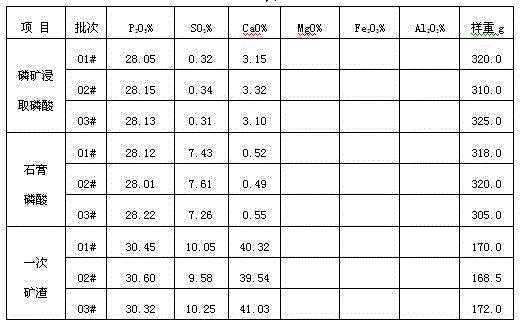

[0026] Take P 2 o 5 Add 600g of 20wt% wet-process phosphoric acid and 100g of dry mineral powder into a 1000ml beaker at the same time, and stir at 350r / min for 2h at 80°C. Stop stirring and let stand for 10 minutes, filter the gypsum slag, dry and weigh the gypsum slag. Add 30g of 98wt% concentrated sulfuric acid to the filtered clear liquid, stir for 10 minutes, let stand for 40 minutes, filter the white phosphogypsum, dry and weigh the white phosphogypsum. The filtrate phosphoric acid was weighed for detection. The parameters of wet-process phosphoric acid and slag powder are shown in Table 4, and the result data are shown in Table 5 and Table 6:

[0027] Table 4

[0028] table 5

[0029]

[0030] Table 6

[0031]

[0032] From the above data, it can be seen that wet-process phosphoric acid and mineral powder are fed at a ratio of 6:1, and the average conversion...

Embodiment 3

[0034] Take P 2 o 5 Add 600g of 20wt% wet-process phosphoric acid and 50g of dry mineral powder into a 1000ml beaker at the same time, and stir at 350r / min for 2h at 80°C. Stop stirring and let stand for 10 minutes, filter the gypsum slag, dry and weigh the gypsum slag. Add 30g of 98wt% concentrated sulfuric acid to the filtered clear liquid, stir for 10 minutes, let stand for 40 minutes, filter the white phosphogypsum, dry and weigh the white phosphogypsum. The filtrate phosphoric acid was weighed for detection. The parameters of wet-process phosphoric acid and slag powder are shown in Table 7, and the result data are shown in Table 8 and Table 9:

[0035] Table 7

[0036] Table 8

[0037]

[0038] Table 9

[0039]

[0040] It can be seen from the above data that: wet-process phosphoric acid and mineral powder are fed at a ratio of 12:1, the amount of phospho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com