OSB ecological painting-free decorative surface furniture plate and preparing method thereof

A technology for furniture boards and finishes, applied in the field of decorative materials, can solve problems such as high hygroscopic expansion rate, poor bearing capacity, and poor dimensional stability, and achieve the effects of improving moisture resistance, ensuring flatness, and high environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

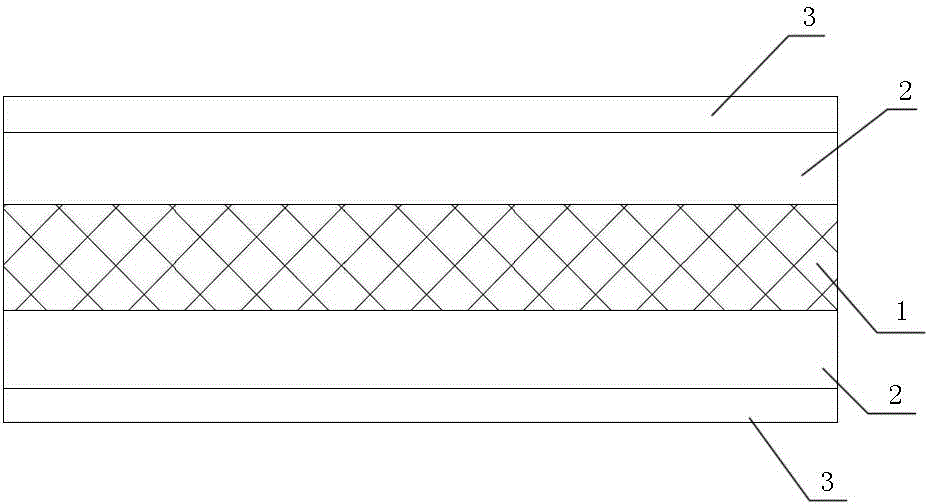

[0025] Embodiment 1: a kind of preparation method of above-mentioned OSB ecological paint-free finish furniture board of the present invention, it comprises the steps:

[0026] a) The production of OSB slabs, the raw materials are processed into thin and long wood chips with a length of 40-120mm along the wood grain direction, a width of 5-20mm, and a thickness of 0.3-0.7mm, which are paved into 3 or 4 layers vertically and horizontally by gluing The staggered structure is made by continuous hot pressing process;

[0027] b) Composite by direct pasting method, the above-mentioned OSB base plate and 0.1-3.0mm thick veneer are pasted with E0 glue to form an OSB substrate, and then the surface of the OSB substrate is covered with a layer of impregnated paper finish layer.

[0028] In the step b), the bonding hot-pressing process parameters of the OSB substrate and the impregnated paper are unit pressure 0.5-1.5 MPa, time 3-15 min, temperature 110-180°C.

Embodiment 2

[0029] Embodiment 2: the preparation method of a kind of above-mentioned OSB ecological paint-free facing furniture board of the present invention, it comprises the steps:

[0030] a) The production of OSB slabs, the raw materials are processed into thin and long wood chips with a length of 40-120mm along the wood grain direction, a width of 5-20mm, and a thickness of 0.3-0.7mm, which are paved into 3 or 4 layers vertically and horizontally by gluing The staggered structure is made by continuous hot pressing process;

[0031] b) Compounding by pasting method, now compound the veneer with a thickness of 0.1-3.0mm and impregnated paper to form a cardboard composite facing layer, and then glue the cardboard composite facing layer to the OSB blank with EO glue.

[0032] In the step b), the hot pressing process parameters when the veneer is combined with the impregnated paper are unit pressure 0.5-1.5 MPa, time 50-100s, and temperature 110-180°C. The hot-pressing process is a unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com