Full-automatic multi-station firecracker insertion and guide machine and working method thereof

A multi-station, fully automatic technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as unsatisfactory insertion quality, incompleteness, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

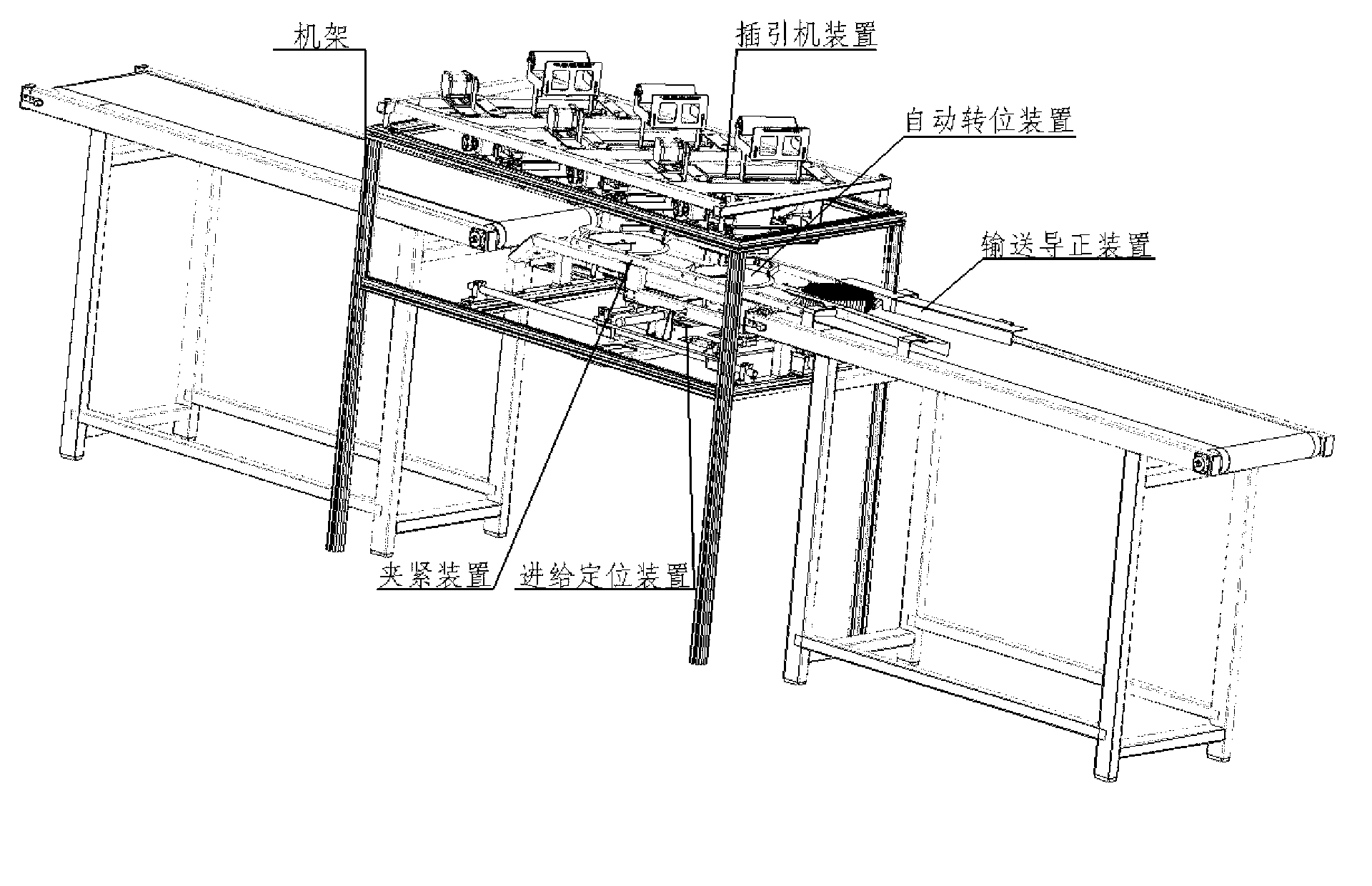

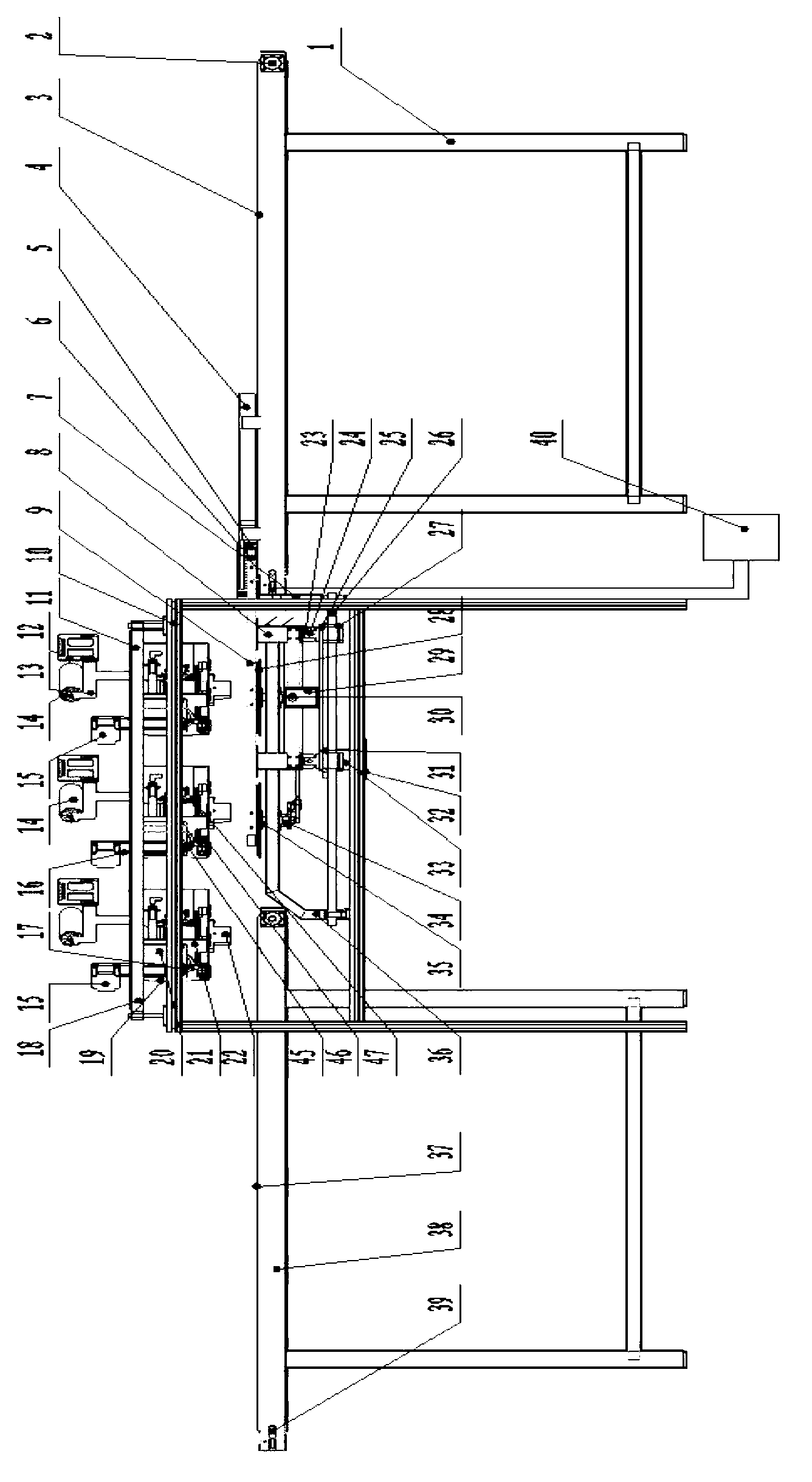

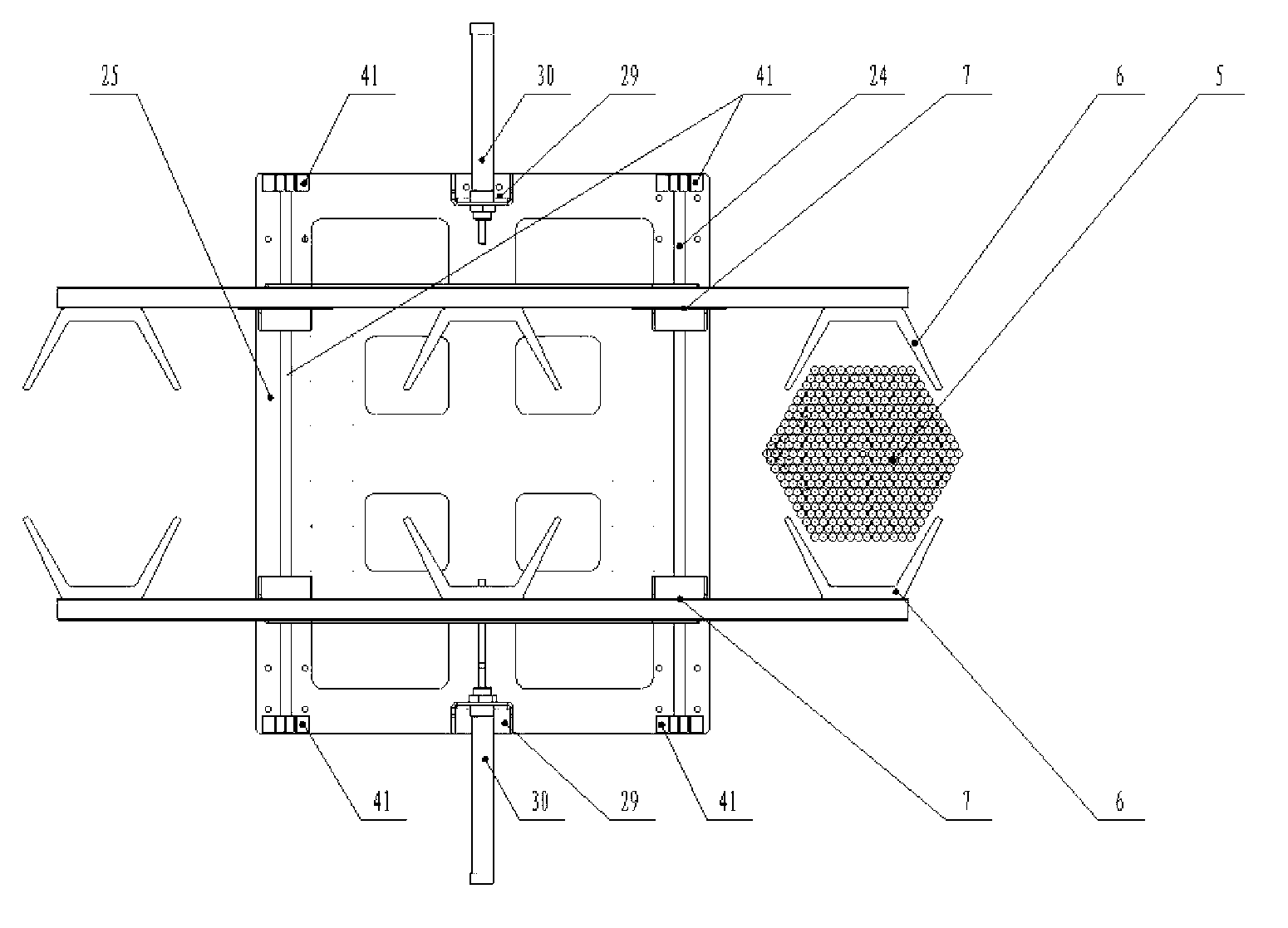

[0057] The present invention is a fully automatic multi-station firecracker inserting machine, figure 1 It is a three-dimensional schematic diagram of the overall structure of the present invention, showing several main parts of the automatic multi-station firecracker inserting and drawing machine: conveying and guiding device, feeding and positioning device, automatic indexing device, inserting and drawing machine device, clamping device . figure 2 It is the front view of the overall structure of the present invention, image 3 It is a top view of the clamping device of the present invention, Figure 4 It is the front view of the indexing device of the present invention, Figure 5 It is the front view of the feed positioning device of the present invention, Figure 6 for the present invention Figure 5 Enlarged view of part I in, Figure 7 It is a three-dimensional schematic diagram of the clamping, indexing, feeding and positioning device of the present invention.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com