Drilling and insertion guiding mechanism for firecracker assembling

A technology for grouping pots and fireworks, which is applied in the direction of pyrotechnics, offensive equipment, weapon types, etc. It can solve the problems of lead wire ignition, easy lead out lead wire, and hinder lead wire entry, etc., so as to avoid the trouble of moving and positioning, good working stability, The effect of reducing the occurrence of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

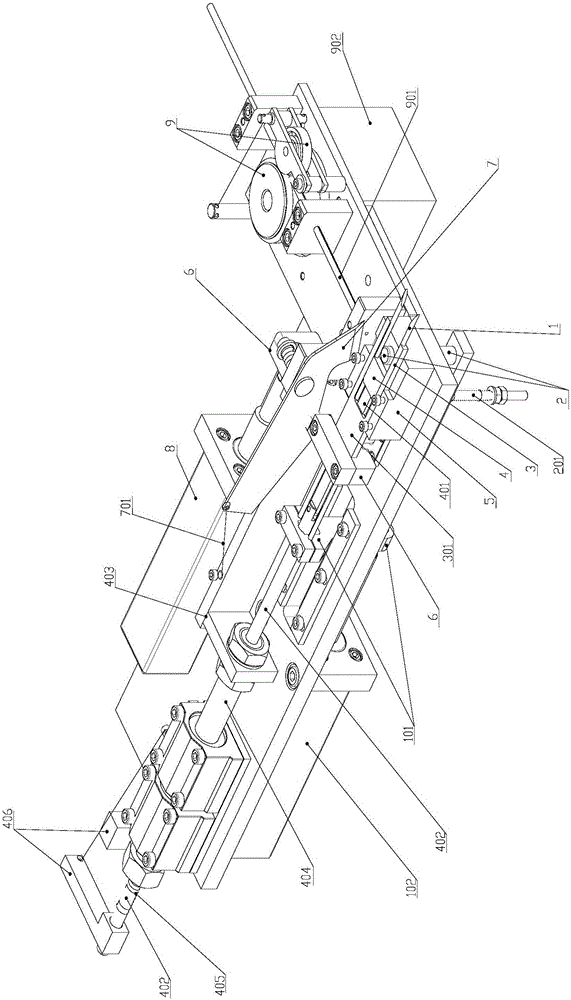

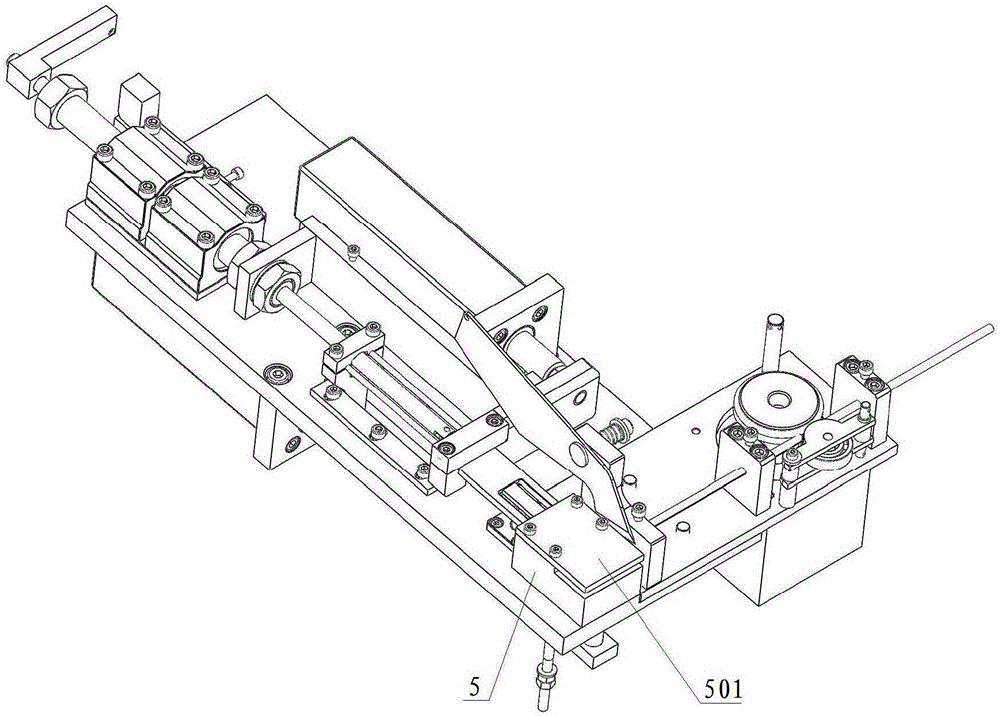

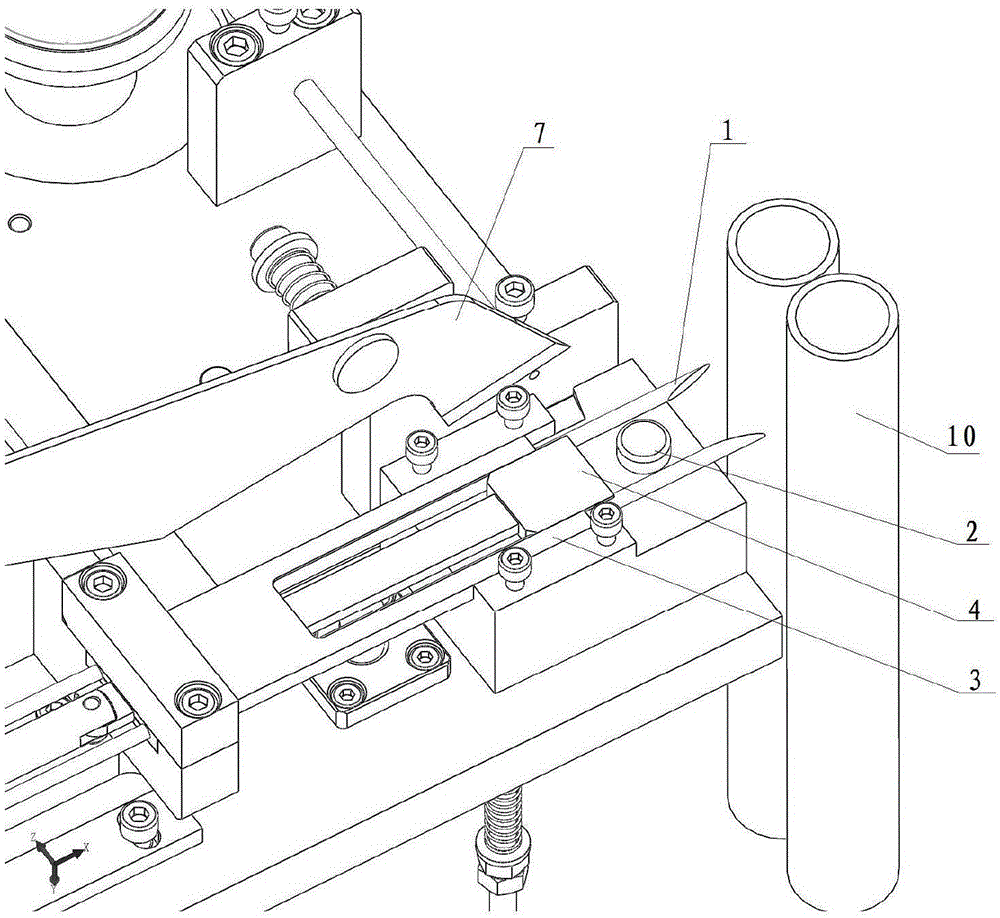

[0036] see figure 1 , reflecting a specific structure of the present invention, the described drilling and inserting mechanism for the firework pots includes two reciprocating motions up and down (the direction toward the fireworks tube in the figure is down, vice versa, up, the same below). Forming guide grooves 3, the notches of two forming guide grooves 3 are relatively arranged; all device drilling needles 1 in the cavity 302 of the two forming guiding grooves 3, and drilling needles 1 move up and down along the groove cavity 302; A pusher 4 that can move back and forth up and down is installed between the root forming guide grooves 3; a forming core 2 that can be telescopically moved inside and outside (the bottom of the figure is inside, and vice versa, the same below) is installed between the two forming guide grooves 3 , the forming core 2 in the protruding state blocks the downward movement of the pushing member 4 .

[0037] The groove end plate 301 at the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com