Semi-automatic firecracker drum washing and forming machine

A molding machine, semi-automatic technology, applied in the direction of weapon types, pyrotechnics, offensive equipment, etc., can solve the problems of increasing personnel costs, time-consuming and laborious, low efficiency, etc., and achieve the effect of improving work efficiency and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

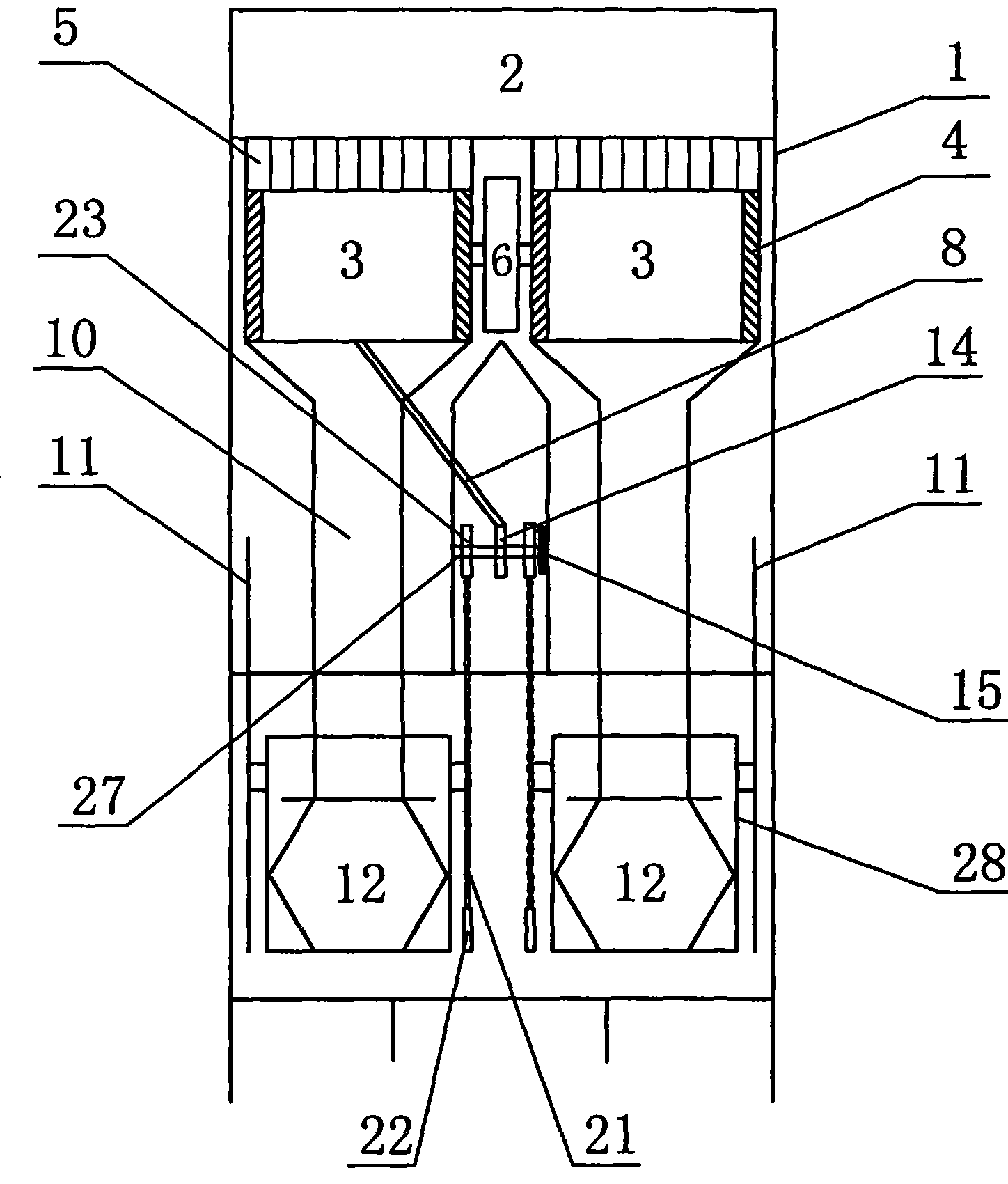

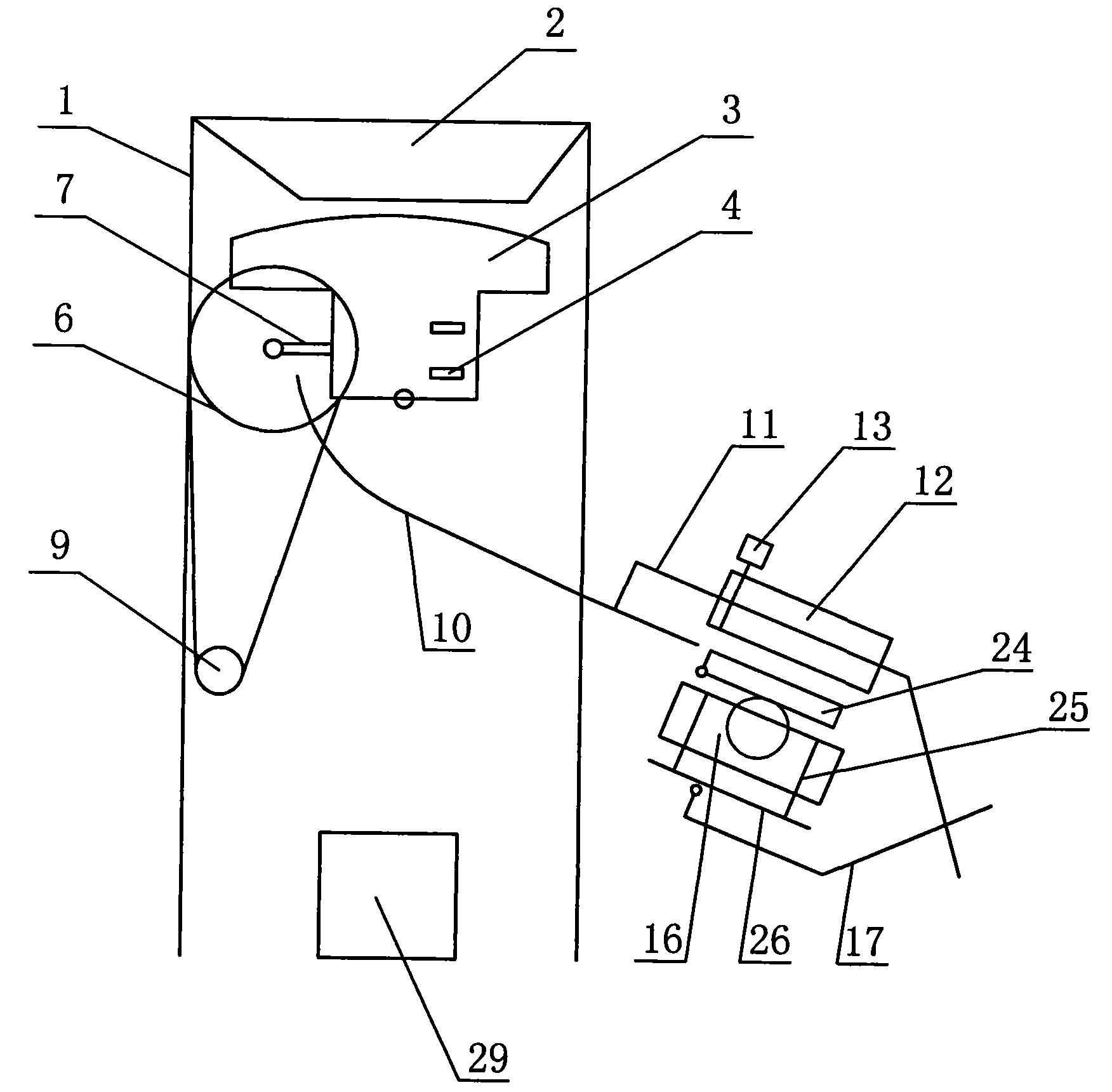

[0014] Below in conjunction with accompanying drawing, the utility model is further described.

[0015] With reference to accompanying drawing: the present embodiment comprises that frame 1, hopper 2, the below of hopper 2 are provided with two swing sieve tube devices 3, the front of hopper 2 and swing sieve tube device 3 is the transparent visible window that is made of plexiglass, The swinging drum 3 drives the belt pulley 6 and the crank connecting rod 7 to make a swinging motion through the motor 9. There are adjustment grooves 4 for adjusting the length of the paper tube on both sides of the swinging drum 3. There are replaceable model size inside the rocking screen drum. The paper tube orientation groove 5 is respectively provided with a discharge channel 10 at the lower outlets of the two swing screen drum devices 3, and an orientation guide rail 11 is respectively provided at the two sides of the two discharge channels, and in the middle of every two orientation guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com