Safety monitoring system and method for firework/cracker manufacturing workshops and storerooms

A safety monitoring system and production workshop technology, applied in the field of safety production monitoring and supervision, can solve the problems of lack of supervision means, lack of monitoring systems and technical methods, inability to early warning and alarm of fireworks and firecracker accidents, etc. The effect of extremely serious and serious accidents, protection of life and property safety, and elimination of major and serious serious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

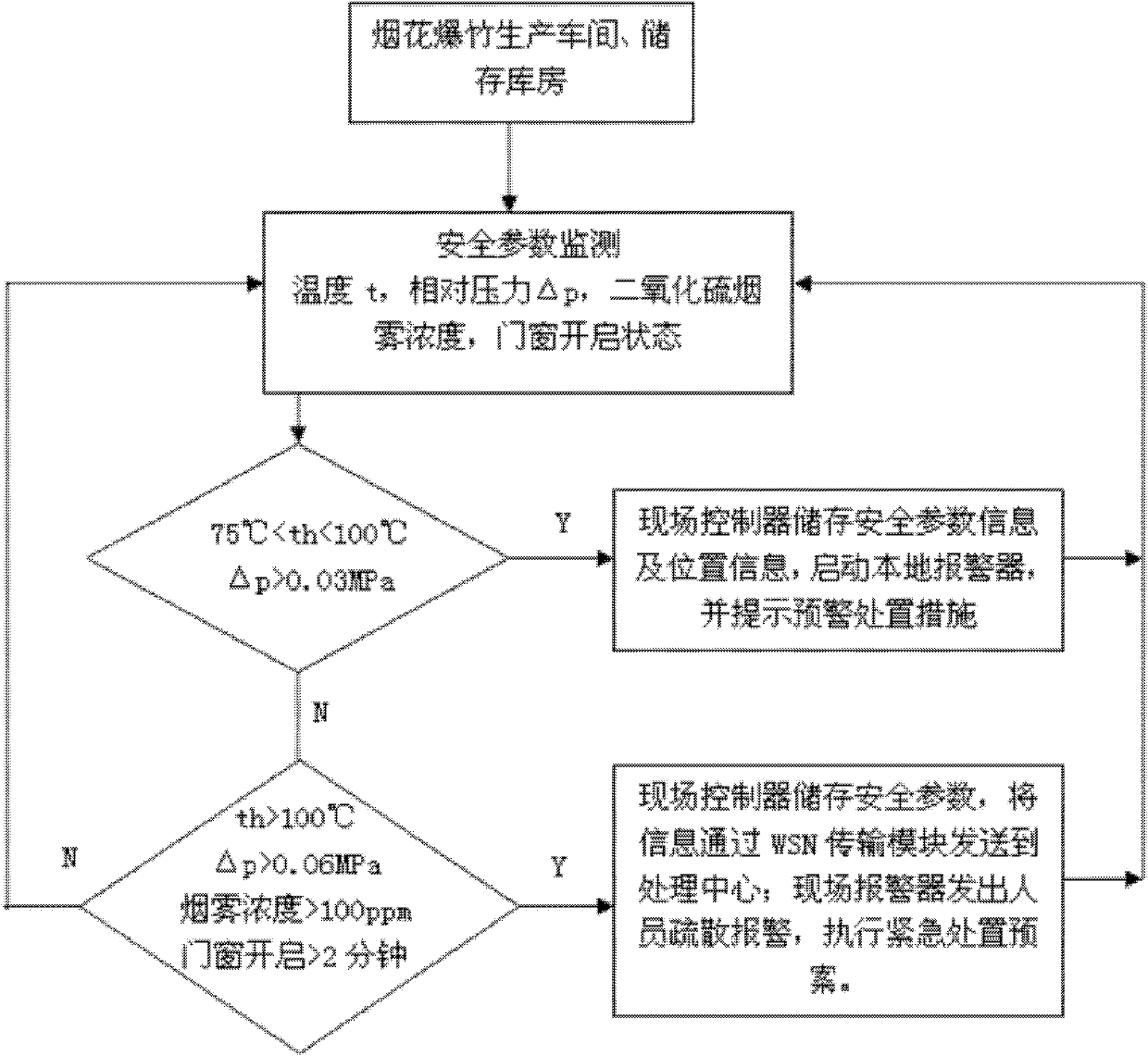

[0030] The safety monitoring system and method of the fireworks and firecracker production workshop and storage warehouse proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments:

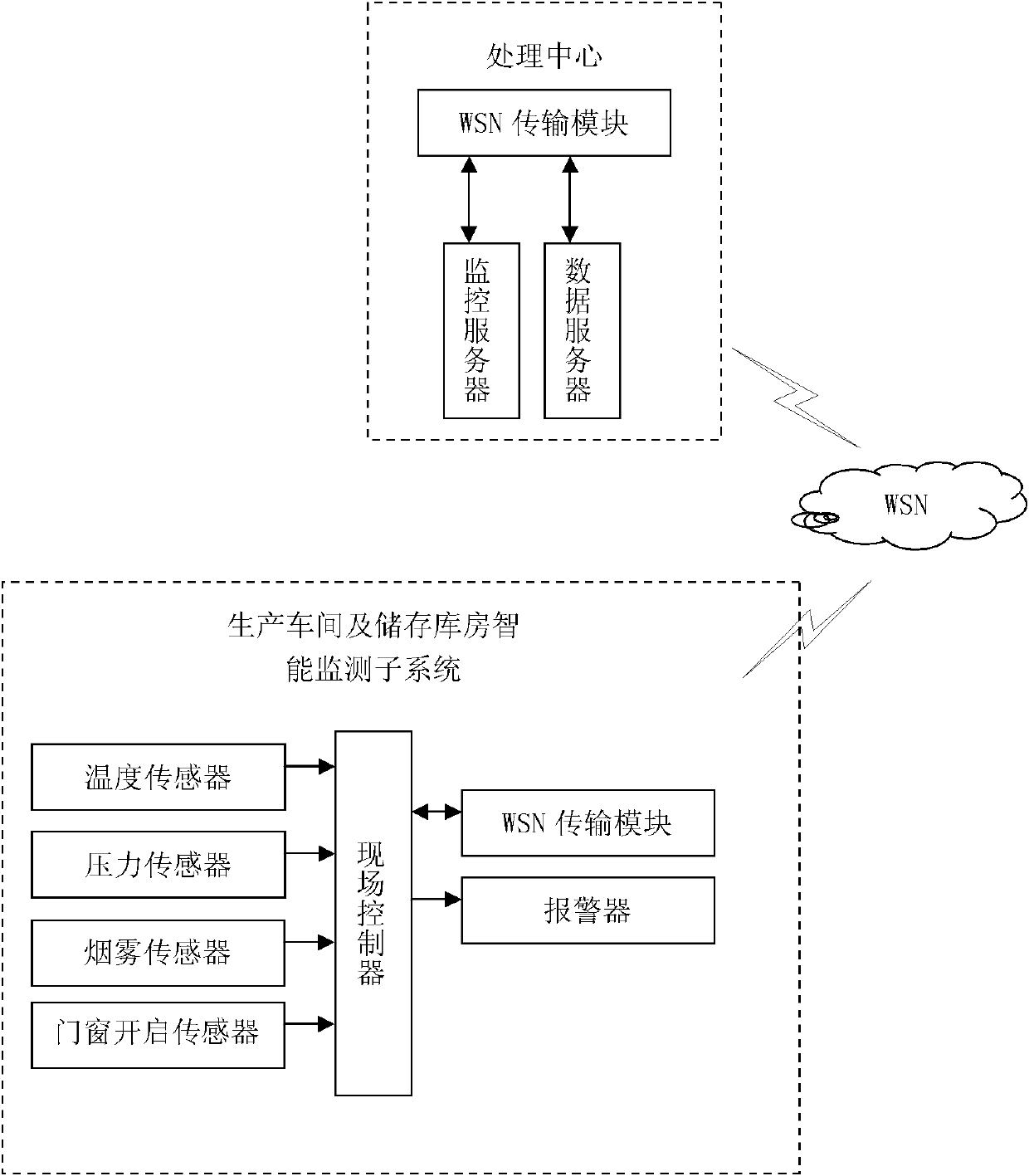

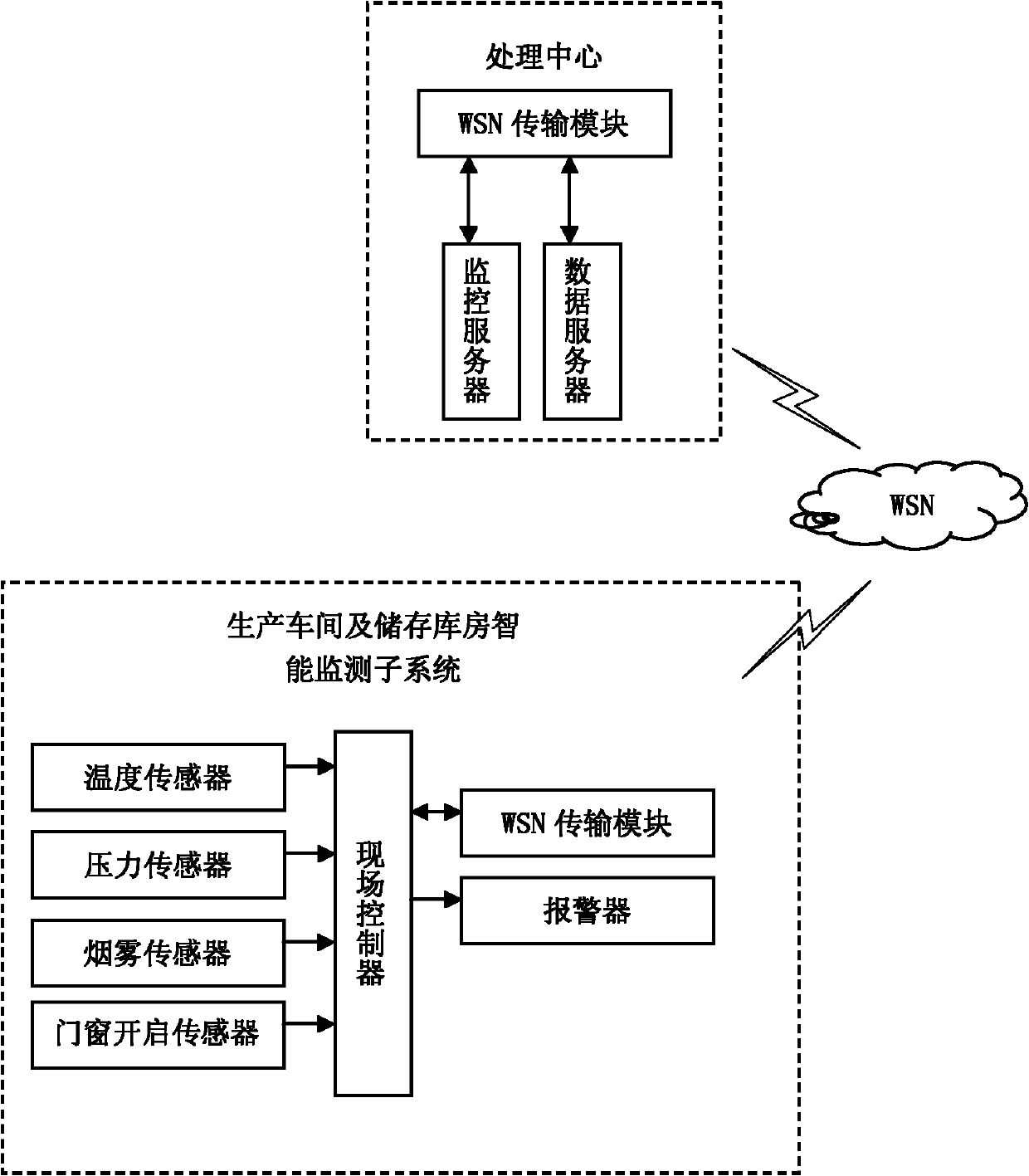

[0031] The fireworks and firecrackers production workshop and storage warehouse safety monitoring system of the present invention includes the fireworks and firecrackers production workshop and storage warehouse intelligent monitoring subsystem and processing center connected by WSN networking, and its overall structure is as follows figure 1 shown.

[0032] Wherein, the intelligent monitoring subsystem includes an on-site controller and a temperature sensor, a pressure sensor, a sulfur dioxide smoke sensor, a door and window opening sensor, an alarm and a WSN transmission module connected to the on-site controller. The on-site controller is used for real-time monitoring, collection and processing of safety parameter informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com