Leading wire drying device and leading wire treatment equipment using thereof

A technology of drying device and processing equipment, applied in drying, dryer, heating device and other directions, can solve the problems of low degree of automation, low production efficiency, lack of safety protection facilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

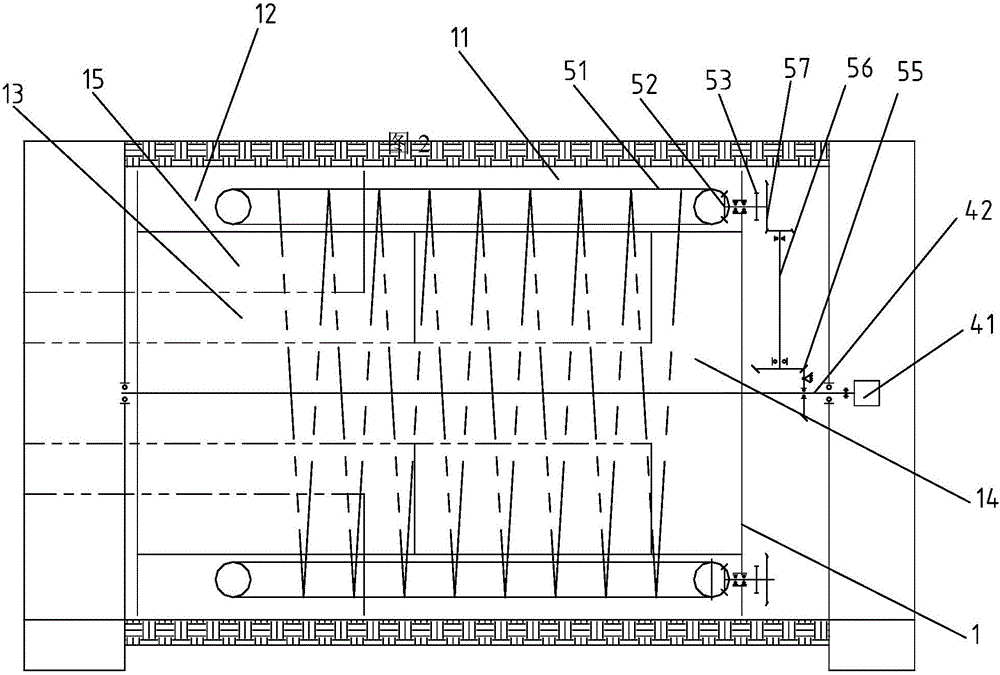

[0033] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

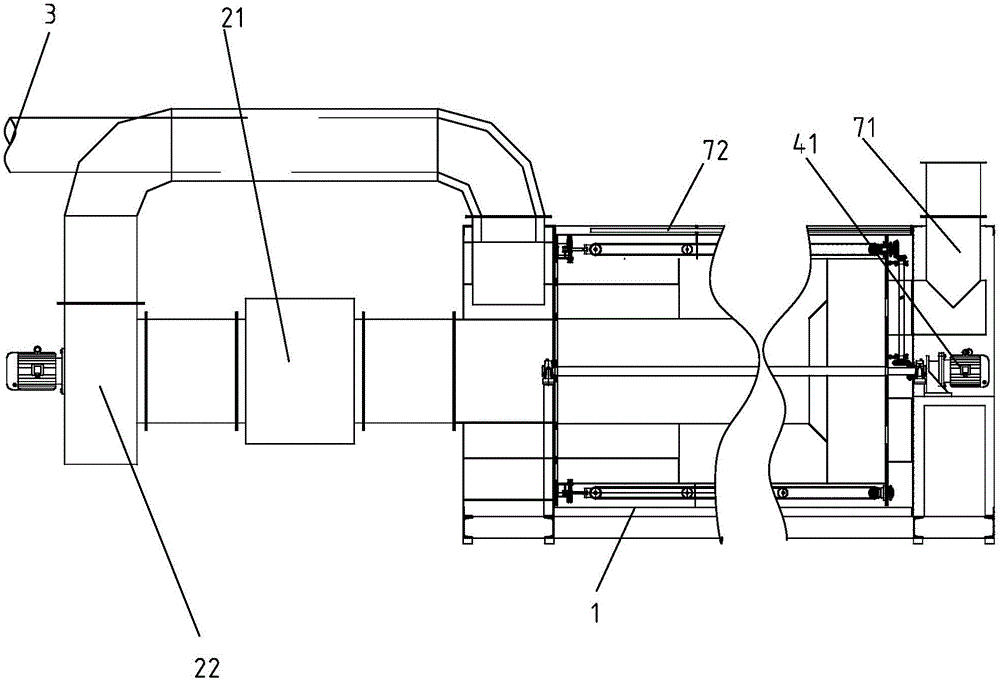

[0034] like Figure 1~4 Shown, a kind of lead wire drying device, it comprises:

[0035] A housing, the housing has an inner cavity, and the housing is provided with a lead wire inlet and a lead wire outlet that both communicate with the inner cavity;

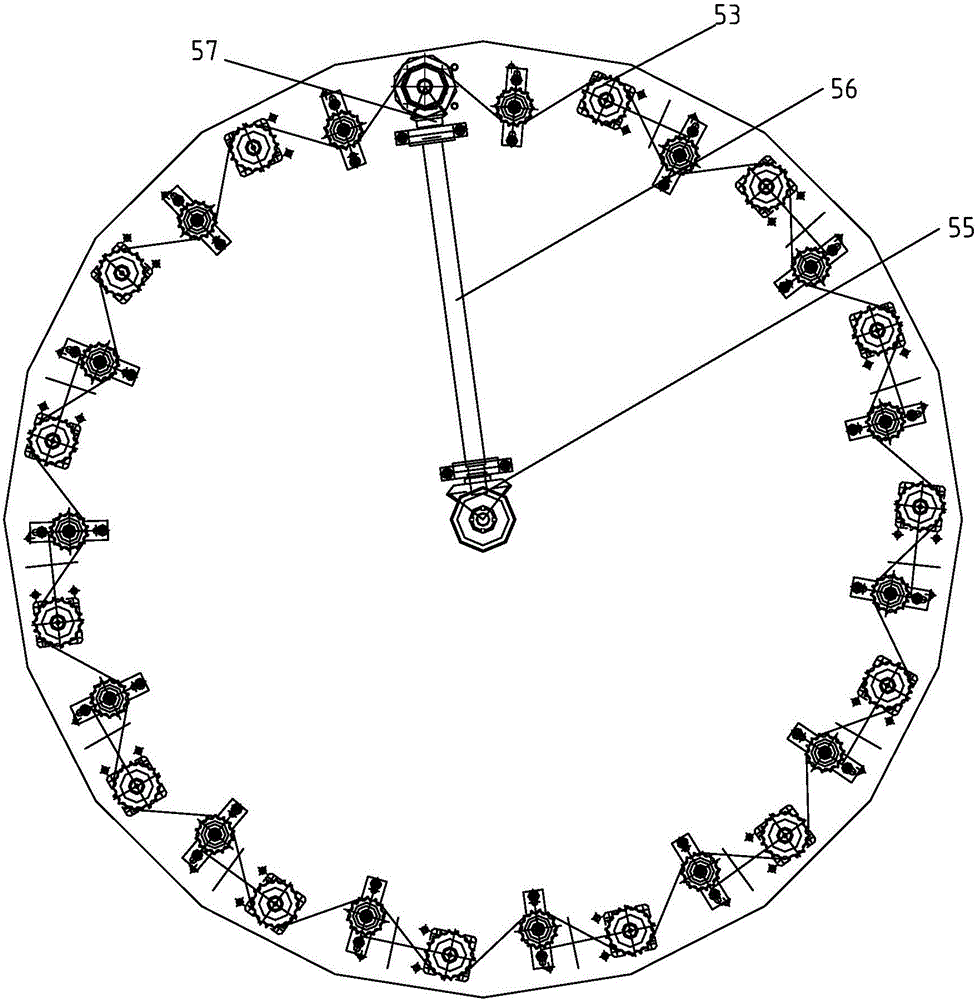

[0036] Inner cylinder 1, the inner cylinder 1 is located in the inner cavity, and the inner cylinder 1 is rotatably supported on the housing, and the inner cylinder 1 is provided with a plurality of lead shafts arranged along the circumference of the inner cylinder To the translation mechanism, the housing is provided with a heating zone 11 and a cooling zone 12 sequentially along the axial direction of the inner cylinder 1, and the lead wire entering from the lead wire inlet is first wound on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com