Industrial detonating fuse automatic curler

A technology of detonating cord and coiling machine, applied in the field of detonating cord, which can solve the problems of inaccurate length of industrial detonating cord, high labor intensity of operators, and influence on company reputation, etc., to ensure the quality of the detonating cord and comprehensive economic Significant benefits, neat and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described by using the drawings and examples.

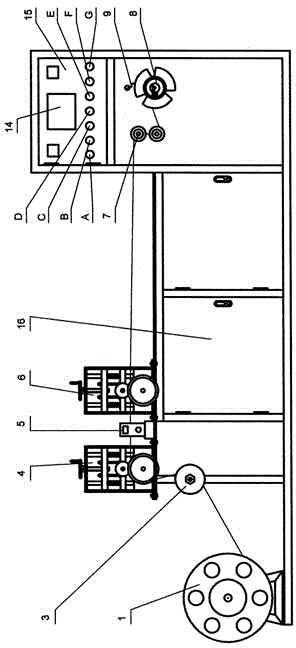

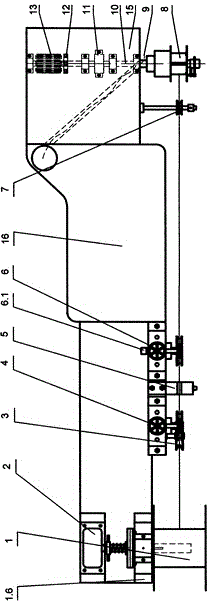

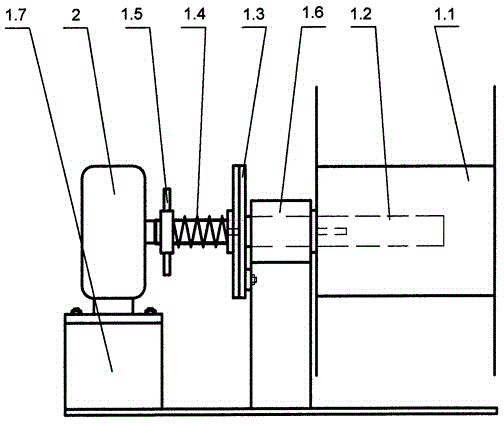

[0029] The industrial detonating cord automatic coiling machine of the present invention comprises a tension-adjustable pay-off wheel device 1, an electromagnetic de-energization brake 2, a guide wheel 3, a crimping device 4, an automatic detection device for surface defects of the detonating cord 5, and a second crimping device. Device 6, a pair of cable reels 7, three locking reel devices 8, binding rope 9, drive shaft 10, electromagnetic clutch 11, deceleration pulley 12, explosion-proof motor 13, PLC control panel 14, electric control cabinet 15, workbench 16. The tension-adjustable pay-off wheel device 1 is supported on the ground on the left side of the workbench 16 by the high support 1.6 and the support 1.7. The electromagnetic power-off brake 2 is installed on the pay-off wheel shaft 1.2. Fixed on the support frame in front of the workbench 16, a crimping device 4, a detonatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com