Production method for preparing detonating tube with low cost and high strength through three-layer co-extrusion and production line thereof

A three-layer co-extrusion and production method technology, applied in the direction of fuse manufacturing, etc., can solve the problems of low tensile strength, low tensile strength and production efficiency of plastic nonel tubes, and inconvenient construction of nonel tubes, so as to overcome the tensile strength small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

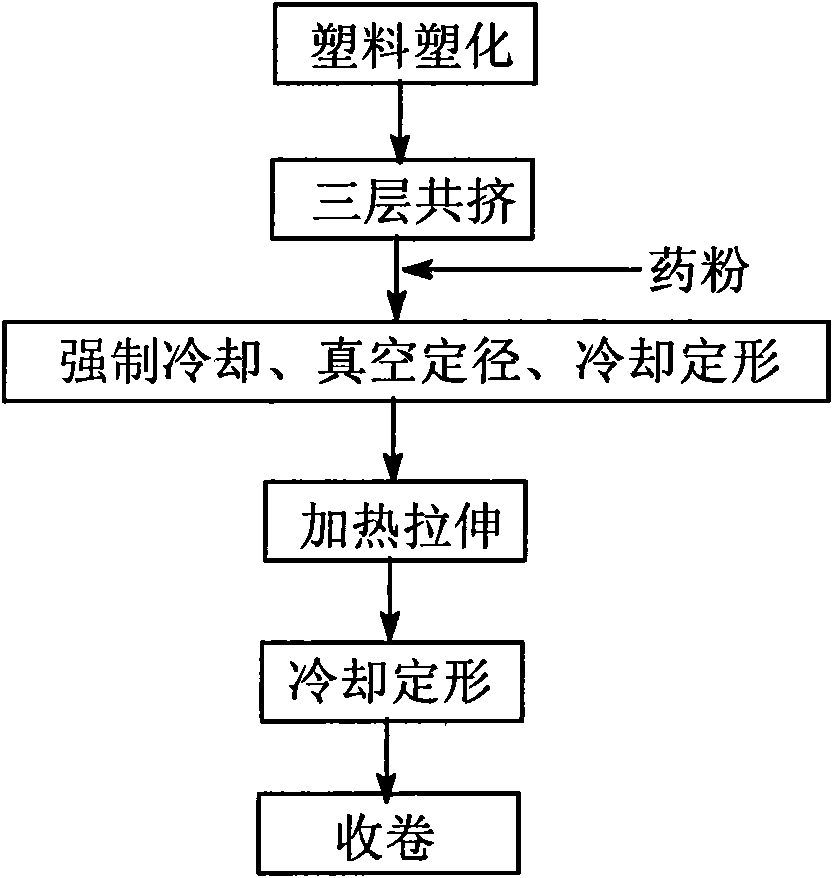

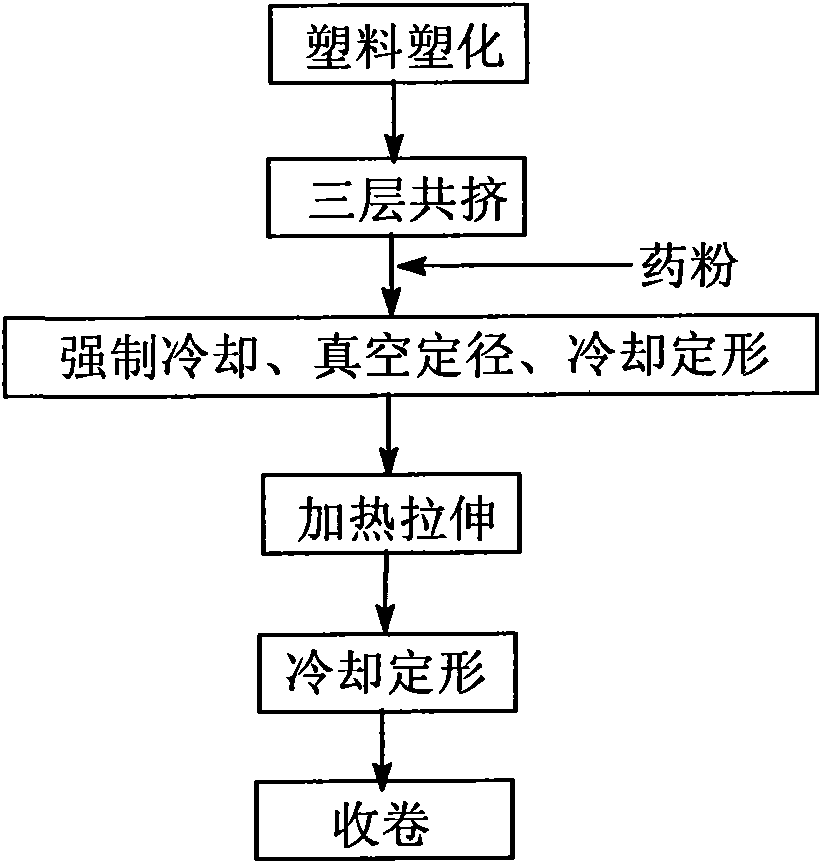

Method used

Image

Examples

Embodiment

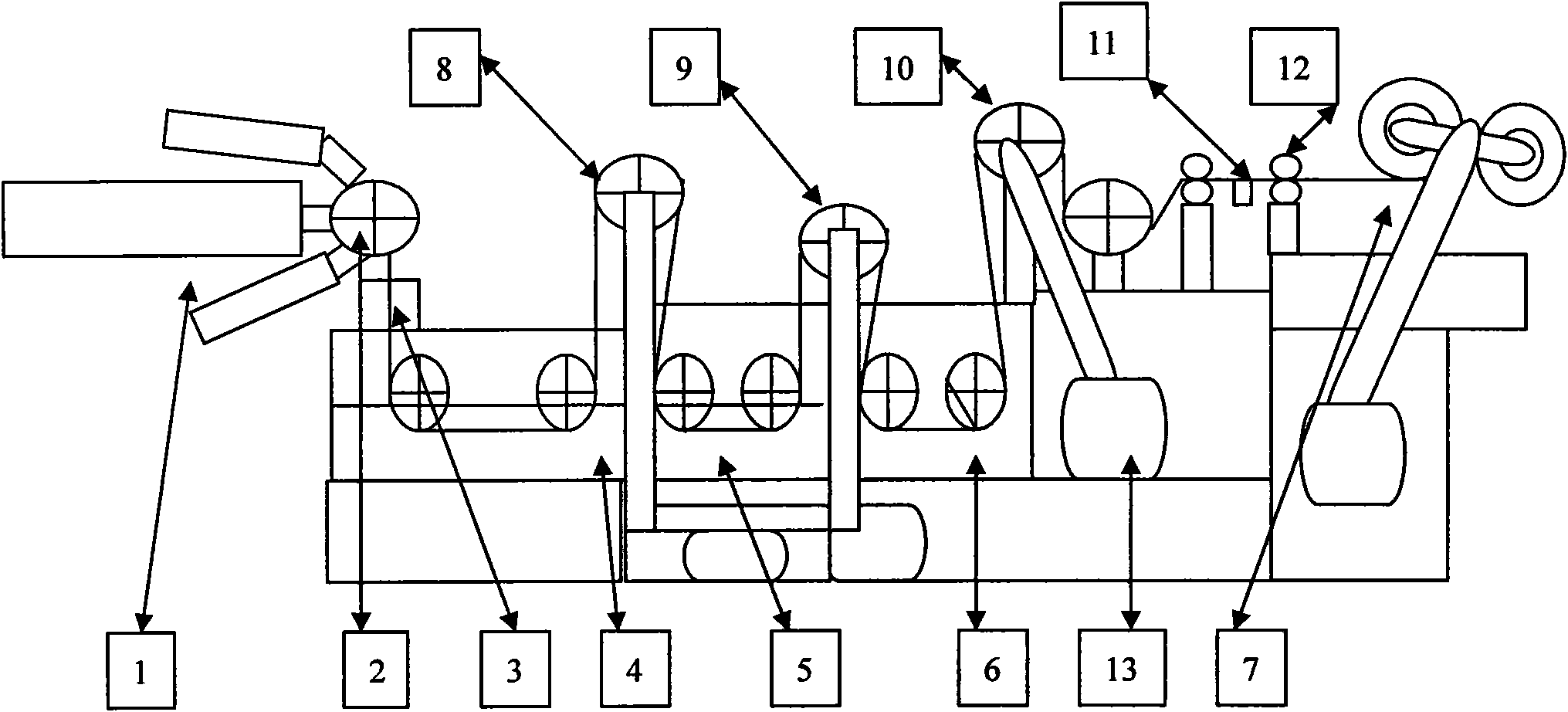

[0039] (1) Three extruders 1¢25 / ¢50 / ¢25 controlled by three frequency conversion motors are used to plasticize the plastic;

[0040] (2) Extrude the plasticized material into the three-layer co-extruded composite die head 2 to form a three-layer co-extruded composite blank tube; wherein the plastic material extruded into the outer layer is a mixture of low-density and high-density polyethylene, accounting for the total 25% of the plastic mass; the plastic material extruded into the core layer is a mixture of low-density polyethylene, high-density polyethylene, polypropylene and nylon, accounting for 50% of the total plastic mass; the plastic material extruded into the inner layer is low-density polyethylene , linear low-density polyethylene and ethylene-vinyl acetate copolymer, accounting for 25% of the total plastic mass; the formed three-layer co-extruded composite blank tube has an outer diameter of 9mm, an inner diameter of 4.5mm, and a wall thickness of 2.25mm.

[0041] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com