Detonator modify process and modify reinforcing means

A reinforcement device and detonator technology, applied in the manufacture of fuses, etc., to achieve the effects of improving tensile strength, reducing plastic structural defects, and improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

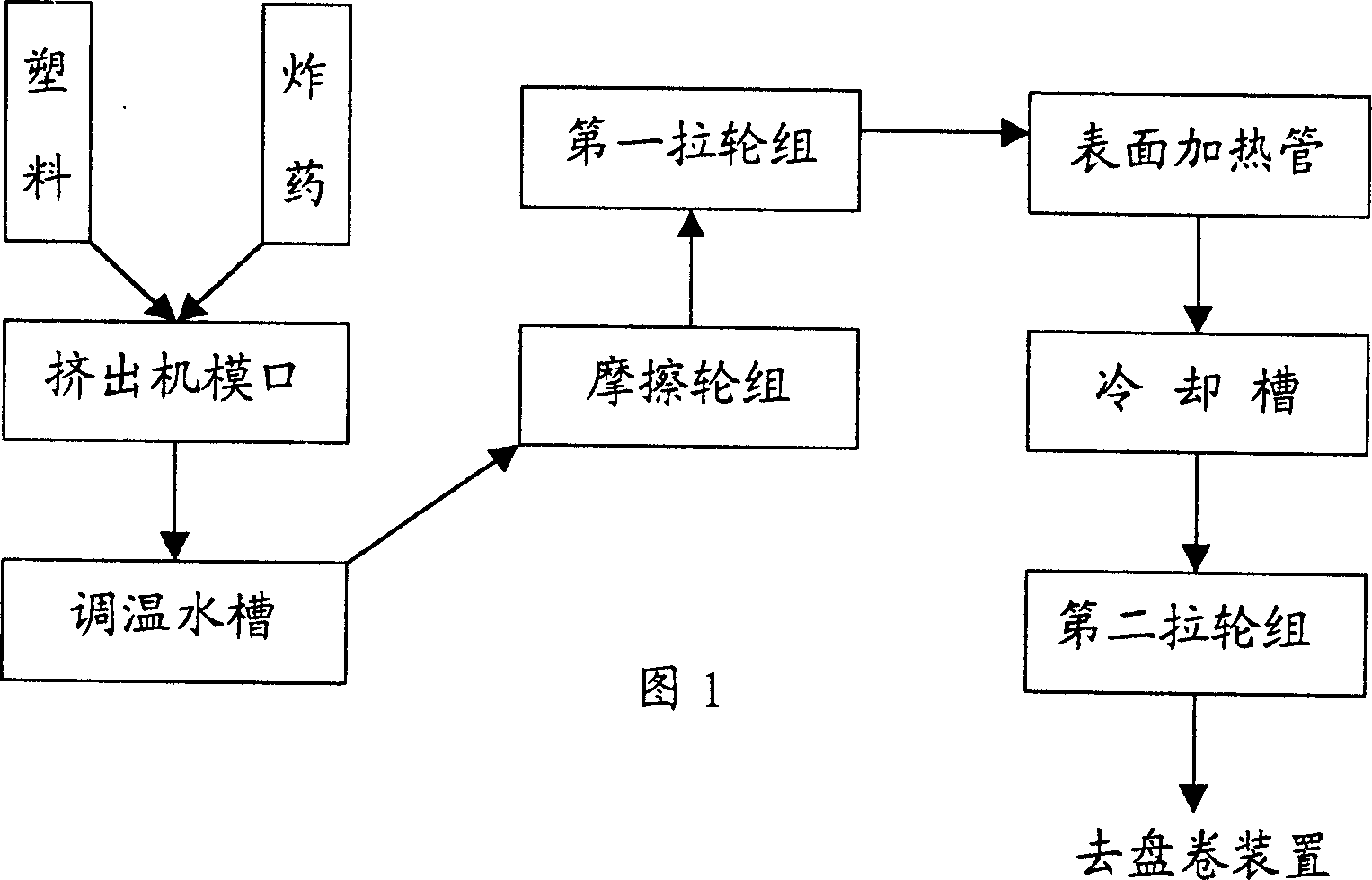

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

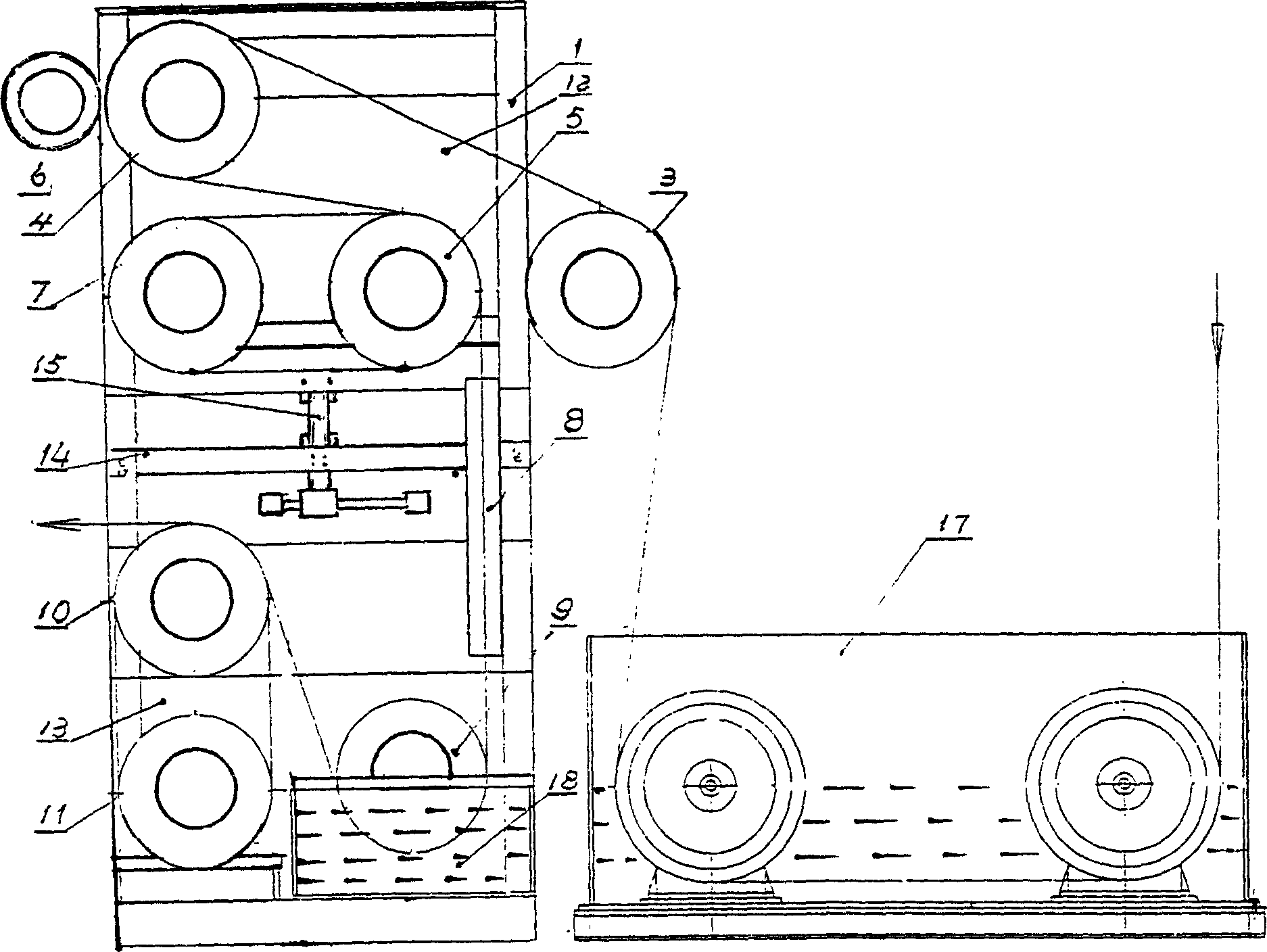

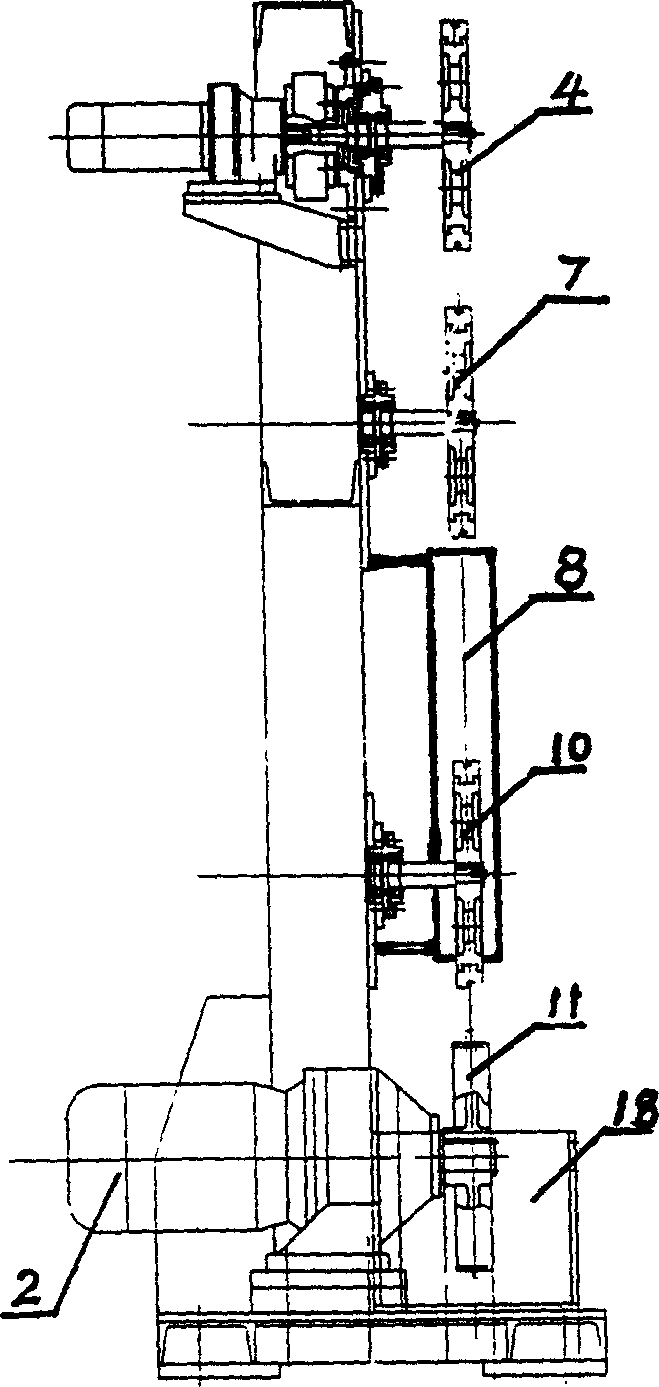

[0018] Such as figure 2 , image 3 As shown, the modified strengthening device of the present invention includes a friction wheel set and a stretching wheel set. The friction wheel set and the stretching wheel are assembled on the frame 1 and driven by a transmission device 2. The friction wheel set consists of a guide wheel 3, a friction wheel The wheel 4 and the pressing wheel 6 are composed of the guide wheel 3 before the friction wheel 4, the friction wheel 4 is tangent to the pressing wheel 6, the temperature regulating water tank 17 is installed in front of the friction wheel group, and two groups of pulleys are installed behind the friction wheel group. The stretching wheel set, the first stretching wheel set is composed of rollers 5 and 7, the second stretching wheel set is composed of rollers 9, 10 and 11, the stretching wheel 5 of the first stretching wheel set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com