Detonating cord machine

A technology of detonating cable machine and frame, which is applied in the manufacture of fuses, etc., and can solve problems such as unstable operation, broken wires, and inability to run parallel at both ends of the trolley.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

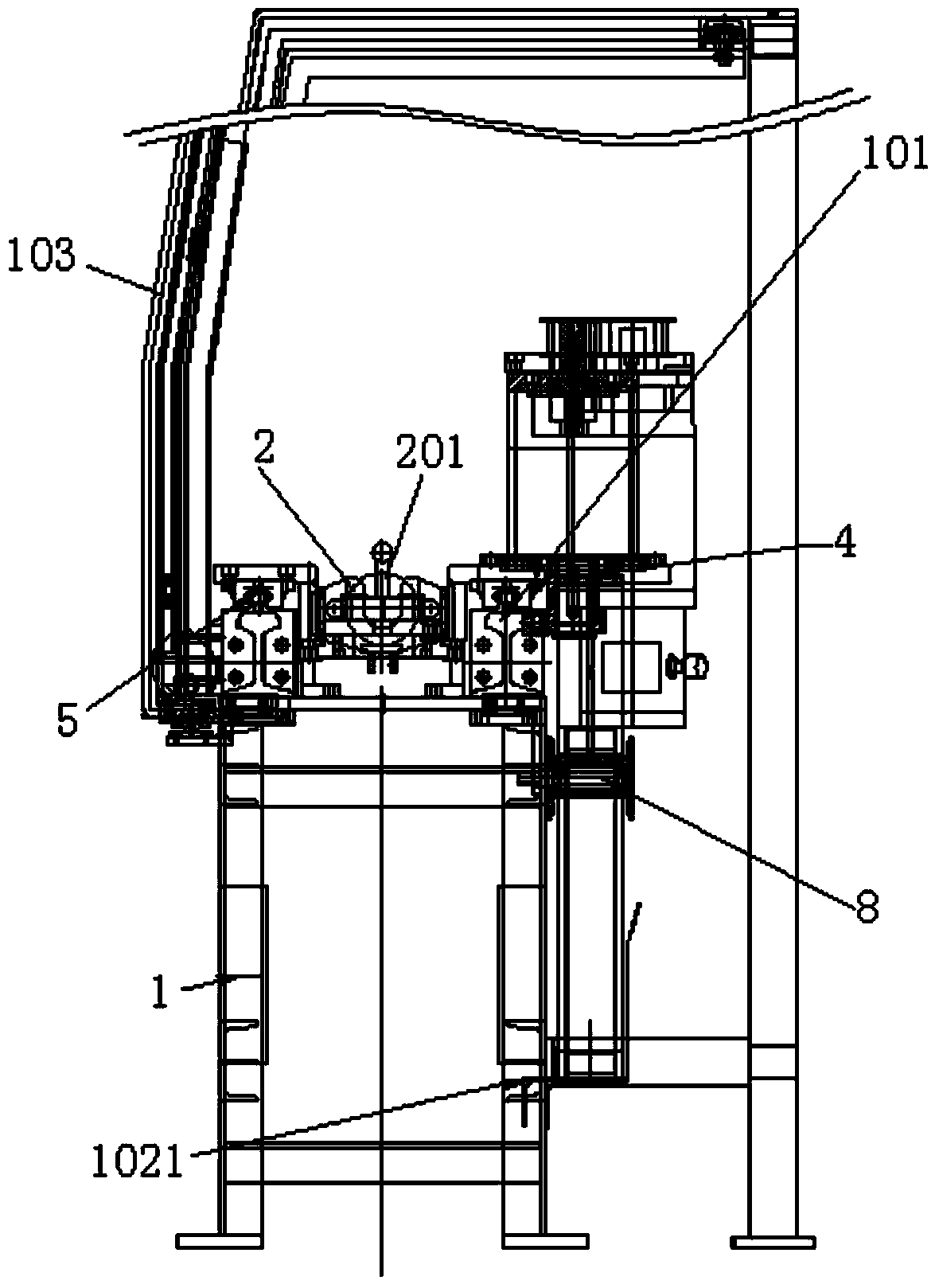

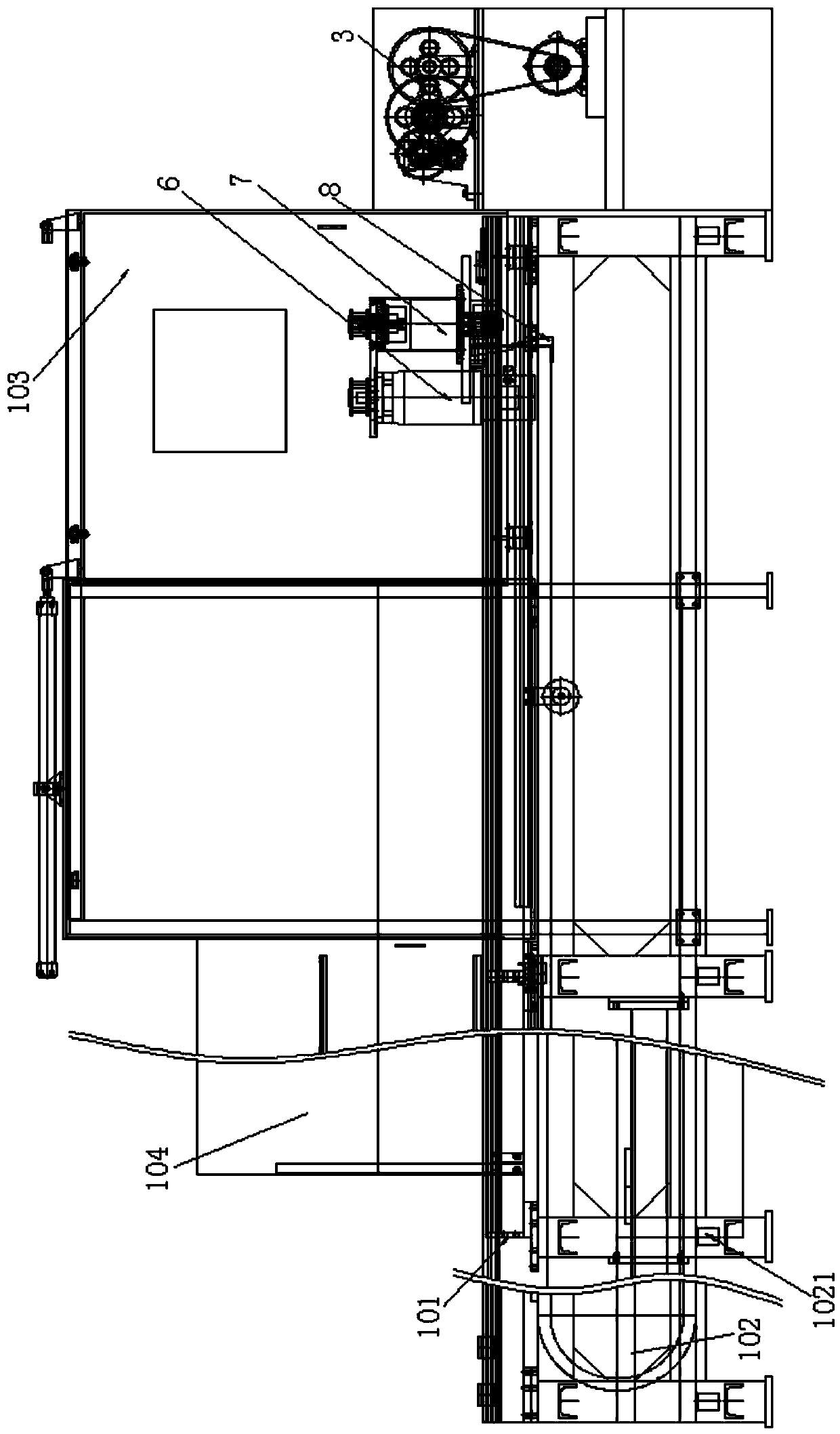

[0012] Referring to the accompanying drawings, a detonating cable machine includes a frame 1, a mobile trolley 2 and a pointing and rolling mechanism 3. The frame 1 is formed by welding channel steel and section steel, and the pointing and rolling mechanism 3 is arranged on the machine. At the operating end of the rack, there are light rails 101 on both sides of the upper end of the rack 1, wherein a rolling support 4 is provided on one side of the light rail, and a linear guide rail 5 is provided on the other side of the light rail, and the rolling support 4 is fixed by a servo motor 6 and a reducer 7. , the lower end is provided with an idler assembly 8, and a mobile trolley 2 is provided between the light rails 1 on both sides. Both ends of the mobile trolley 2 are installed on the light rail 101 through linear slide rails. The lower end of the position is provided with a trunking 102, and the trunking 102 is installed on the frame through the trunking bracket 1021. The tipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com