Combined mold and method for preparing casting type explosives and powders

A technology of combining molds and explosives, used in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of low efficiency, introduced air holes, and large loss, and achieve the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Clamping Mold Casting Manufacturing of Hollow Tablets

[0053] Goal: To manufacture 3mm thick butylated hydroxybutyrate hollow thin slices, the thin slice size is 200mm*165mm, and the central round hole size is Ф120mm.

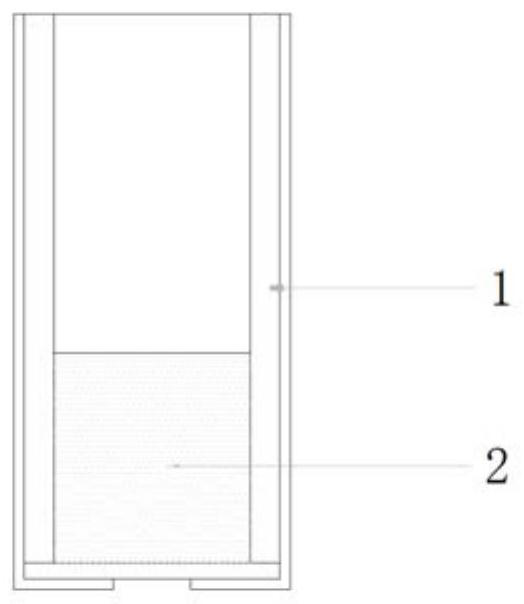

[0054] Step 1, manufacture and degass the hydroxybutylated propellant slurry, use 85% solid content HTPB propellant formula, the basic composition of the formula is HTPB binder system: oxidant AP:Al=15:68:17. The components are weighed according to the general pharmaceutical process of butyl-hydroxyl propellant, and fully mixed with a vertical planetary mixer to obtain pourable butyl-hydroxyl propellant slurry. The general vacuum casting process using composite propellants in e.g. figure 2 Vacuum pour 2kg of slurry in the slurry holding mold 1 to complete the degassing of the slurry;

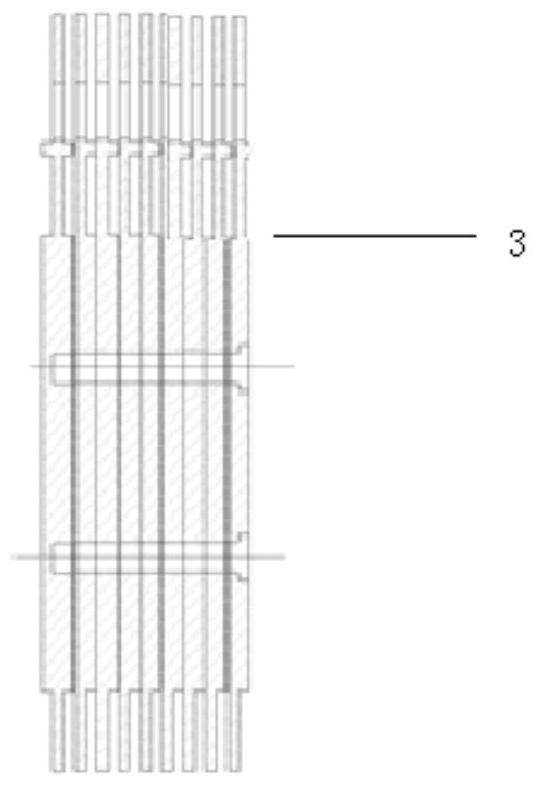

[0055] Step 2, mold clamping and counterflow molding: the figure 1 The counterflow molding die 3 shown is pressed into the figure 2 In the slurry containing mold 1 ...

Embodiment 2

[0058] Pressurized Countercurrent Pouring Manufacturing of Hollow Tablets

[0059] Objective: To manufacture 3mm thick pouring polyether fracturing agent hollow sheets with a size of 180mm*200mm.

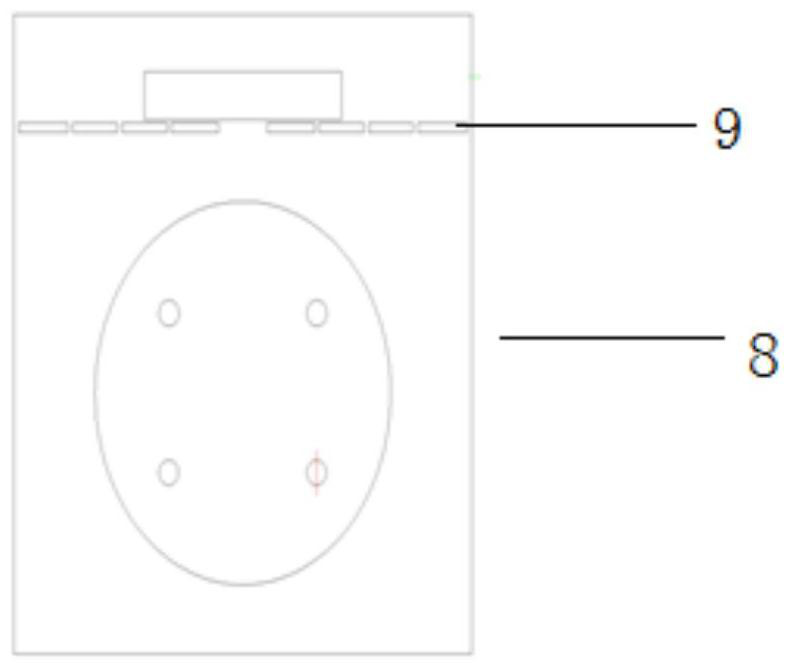

[0060] Step 1, making polyether gas-generating drug slurry and degassing, using 80% solid content polyether gas-generating drug formula, the basic composition of the formula is: polyether adhesive system: mixed nitrate plasticizer: oxidizing agent AP: nitric acid Ammonium = 8:12:55:25. The components are weighed according to the general pharmaceutical process of the composite propellant, and fully mixed with a vertical planetary mixer to obtain a pourable polyether gas-generating drug slurry. The general vacuum casting process using composite propellants in e.g. Figure 5 Vacuum pour 3kg of slurry in the pressurized extrusion pouring tank shown to complete the degassing of the slurry;

[0061] Step 2 pressurized counterflow molding: press Figure 5 The method shown properly conn...

Embodiment 3

[0064] Countercurrent Pouring Manufacturing of Silver-embedded Rods

[0065] Objective: To manufacture high-burning-rate HTPB propellant round bar-shaped silver-embedded medicine rod: the diameter of the medicine rod is Ф7mm, the length is 150mm, and the diameter of the silver-embedded wire is Ф0.3mm.

[0066] Step 1, preset silver wire. similar figure 1 For the counter-flow molding mold shown, the drug mold cavity in the counter-flow molding mold is manufactured as a series of semicircular butt joints with a diameter of 7 mm, and silver wire positioning holes are reserved at both ends of the mold, and the counter-flow molding mold is preset with Ф0.3mm silver wire, and tension the silver wire;

[0067] Step 2: Manufacture high burning rate hydroxybutylene propellant slurry and degas;

[0068] Step 3: Pressurized counterflow molding: press Figure 5 The method shown properly connects the lower opening of the pressurized extrusion pouring tank 4 and the counterflow molding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com