Drying drum and starch guiding machine containing the same

A technology for drying cylinders and cylinders, which is applied in the manufacture of fuses, etc., and can solve the problems of lead wire breakage, lead wire quality influence, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

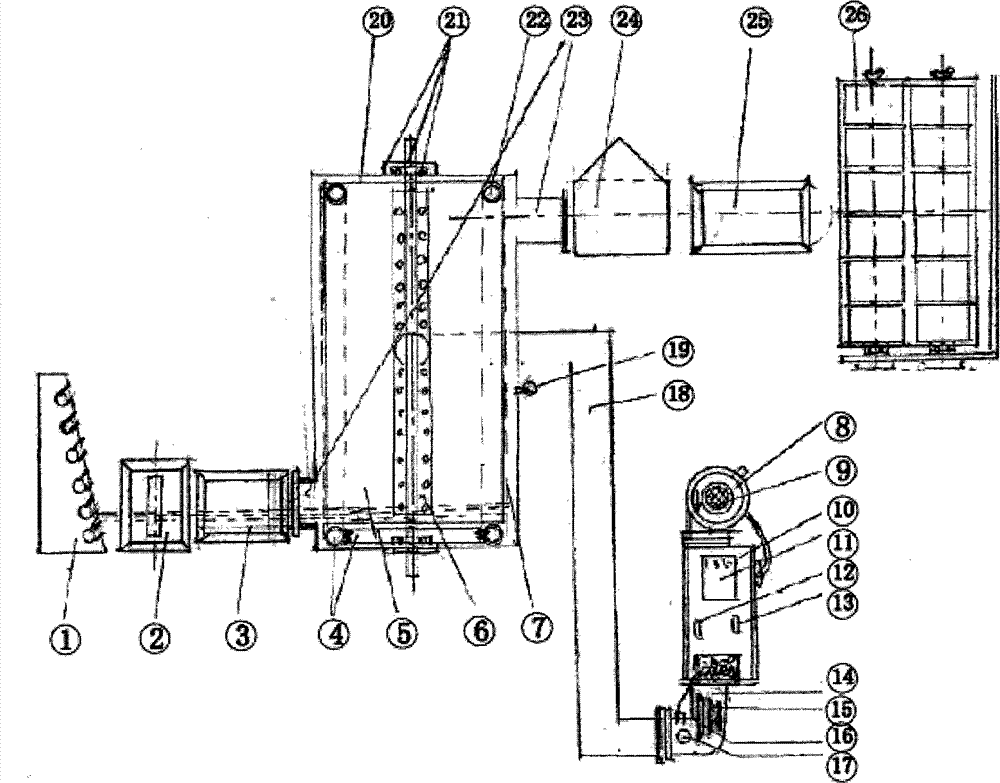

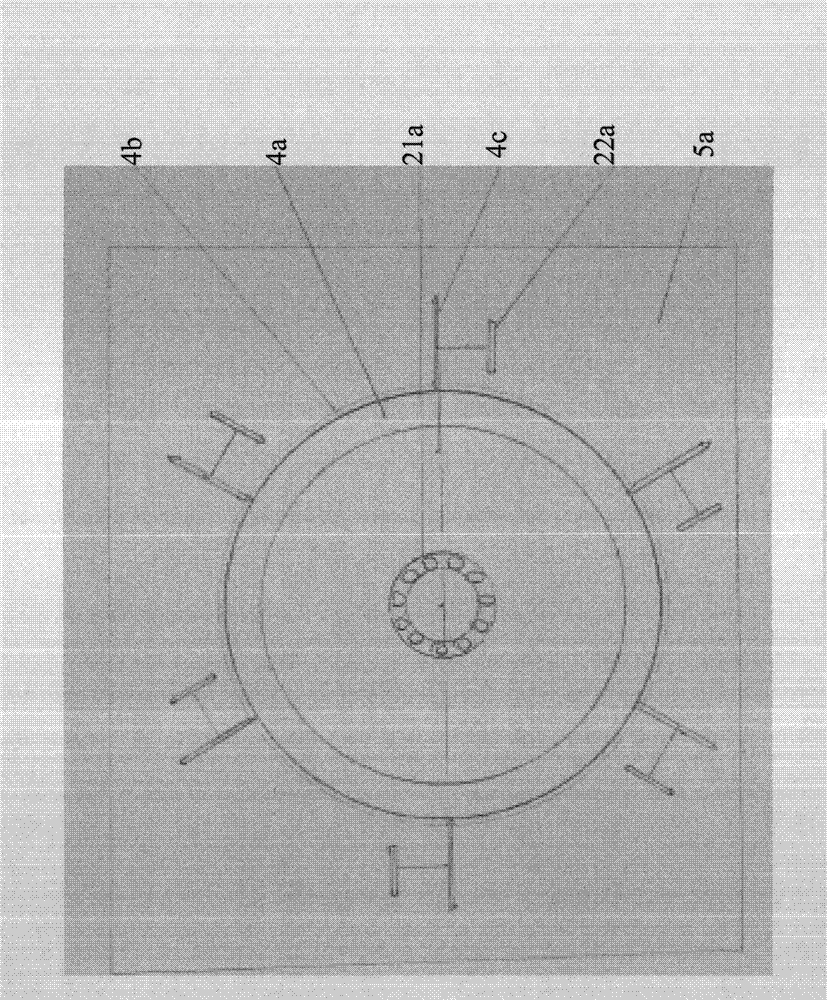

[0059] Such as figure 1 and 2 As shown, the drying cylinder of the present invention includes a cylinder body 5, an inner ring frame 20, a turbine worm 4, a transport belt 7, a pulley 22, a hot air dispersion pipe 6, and a hot air blower 8; the worm 4a is fixed On the bottom surface 5a of the cylinder, a plurality of turbines 4c surround the outer circumference of the worm 4a, and the gears of the worms 4c mesh with the outer helical wire 4b of the worm; since the worm 4a is fixed, each turbine 4c can rotate At the same time, it revolves around the worm 4a along the outer helical wire 4b of the worm; each worm has a pulley 22a coaxial with it, and the pulley 22a will rotate and revolve with the worm 4a; multiple sets of coaxial pulleys 22a and the turbine 4c are fixed on the bottom surface of the inner ring frame 20; the bottom surface of the inner ring frame 20 is circular, located in the sky above the worm rod 4a and parallel to the cylinder bottom surface 5a, the top surfa...

Embodiment 2

[0061] Such as figure 1 and 2 As shown, the structure of the sizing machine according to the present invention mainly includes the sizing box 2 , the drying cylinder described in Embodiment 1, and the winding machine 26 . In the pulp drawing machine of the present invention, the lead wire semi-finished product that has completed the nitration process is taken as the processing object, and the lead wire moves forward under the traction of the winding machine 26 . The lead wire semi-finished product first enters the sizing box 2, and passes between the upper and lower rollers in the sizing box 2, enters the safety water tank 3 after completing the sizing, and then enters the drying cylinder through the drying cylinder inlet 23. In the drying cylinder, the lead wires are wound around the outer sides of a plurality of transport belts 7 on the outer cylindrical surface of the inner ring frame 20; The rotation will drive the turbine 4c fixed on the bottom surface of the inner ring...

Embodiment 3

[0065] Such as figure 1 As shown, the method for preparing a lead wire using the slurry lead machine of embodiment 2 mainly includes the following steps:

[0066] a. Place the lead wire semi-finished product that has been nitrated on the lead wire semi-finished product mounting frame 1;

[0067] b. Pull the lead semi-finished product into the sizing machine described in embodiment 2, pass through the sizing box 2, safety water tank 3, drying cylinder, humidifier 24, and safety water tank 25 successively, and finally wind on the winding machine 26 ; Use the winding machine 26 to pull the semi-finished lead wire to move forward, so that the semi-finished lead wire can be sizing, dried, and humidified in sequence, and finally the finished lead wire can be obtained;

[0068] c. Pack the lead wire finished product in step b, and store it in the finished product transfer room.

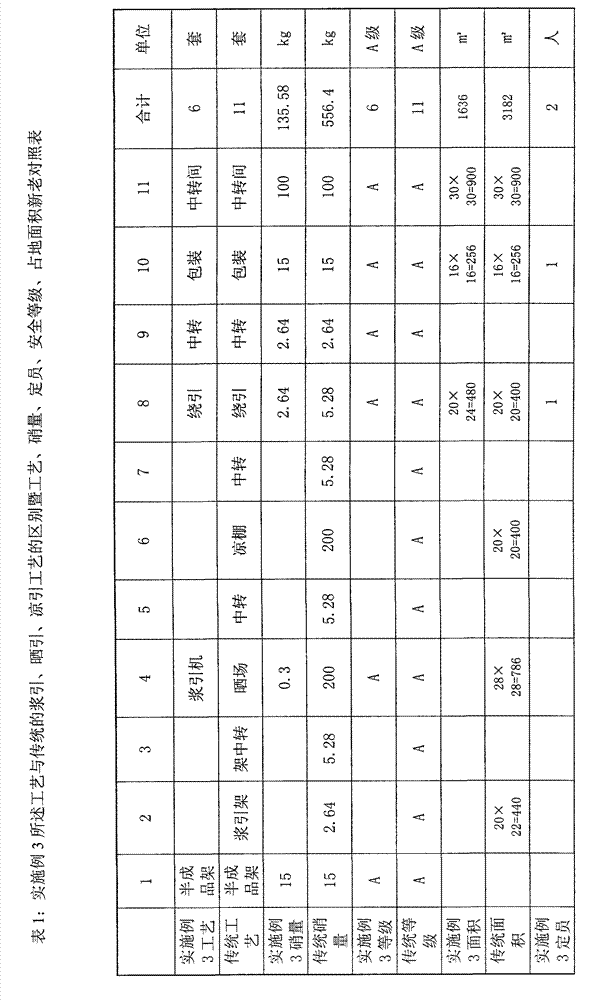

[0069] The process described in embodiment 3 and the traditional slurry drawing, sun-drying and cold-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com