Automatic segmentation sealing and bundling device for plastic detonating tubes

A technology of automatic segmentation and detonating tube, applied in the direction of fuse manufacturing, etc., can solve the problem of no multi-function integrated machine, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

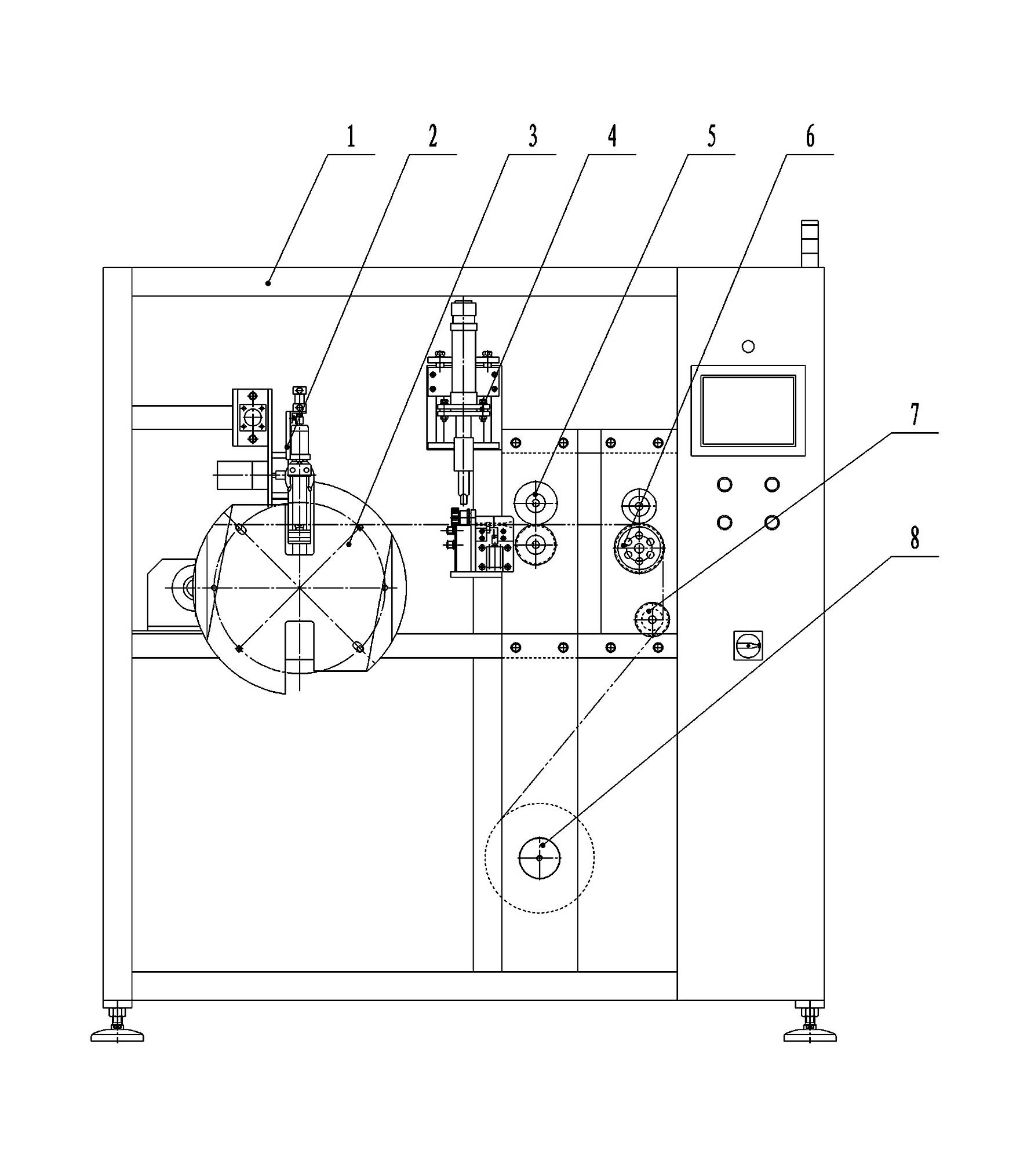

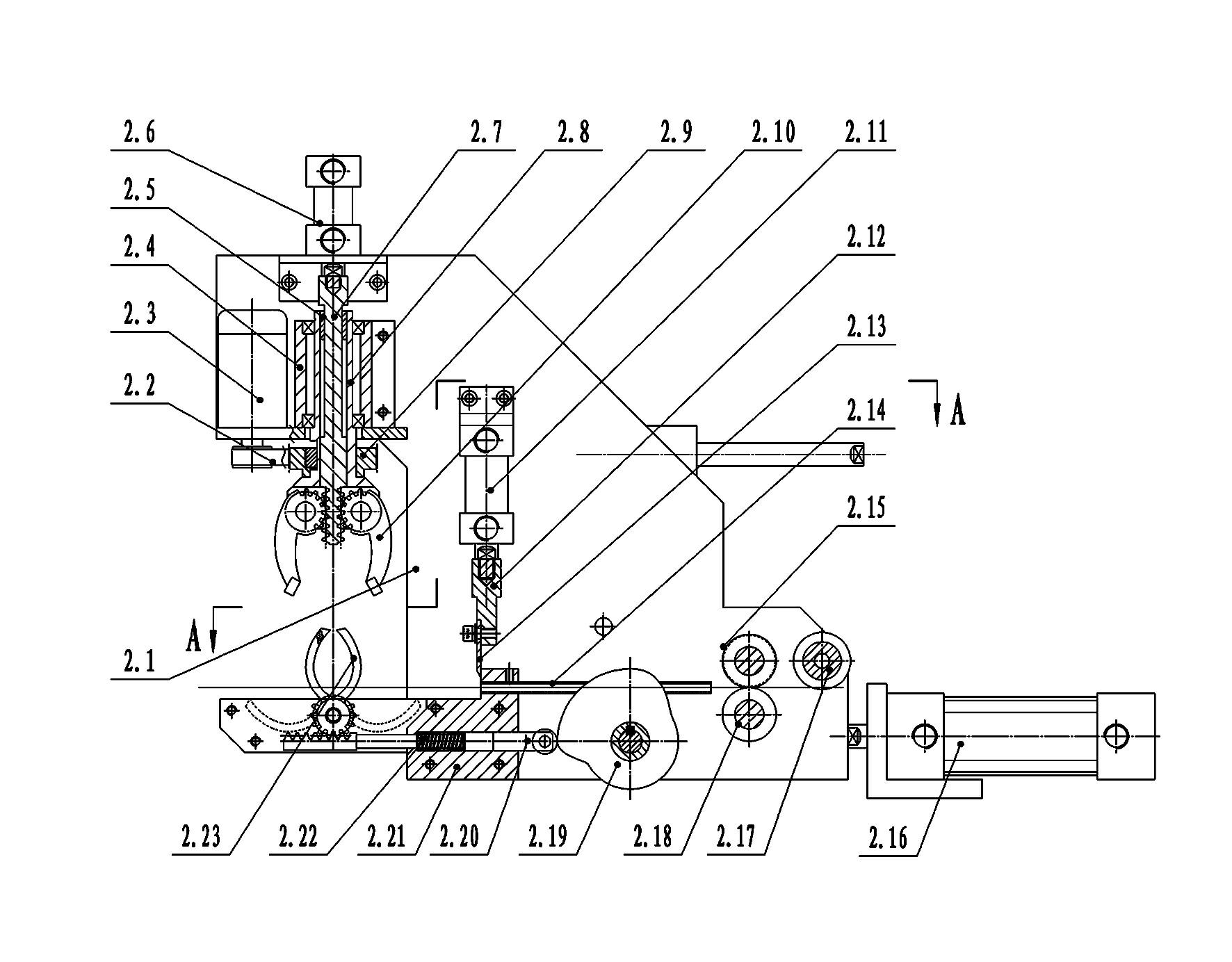

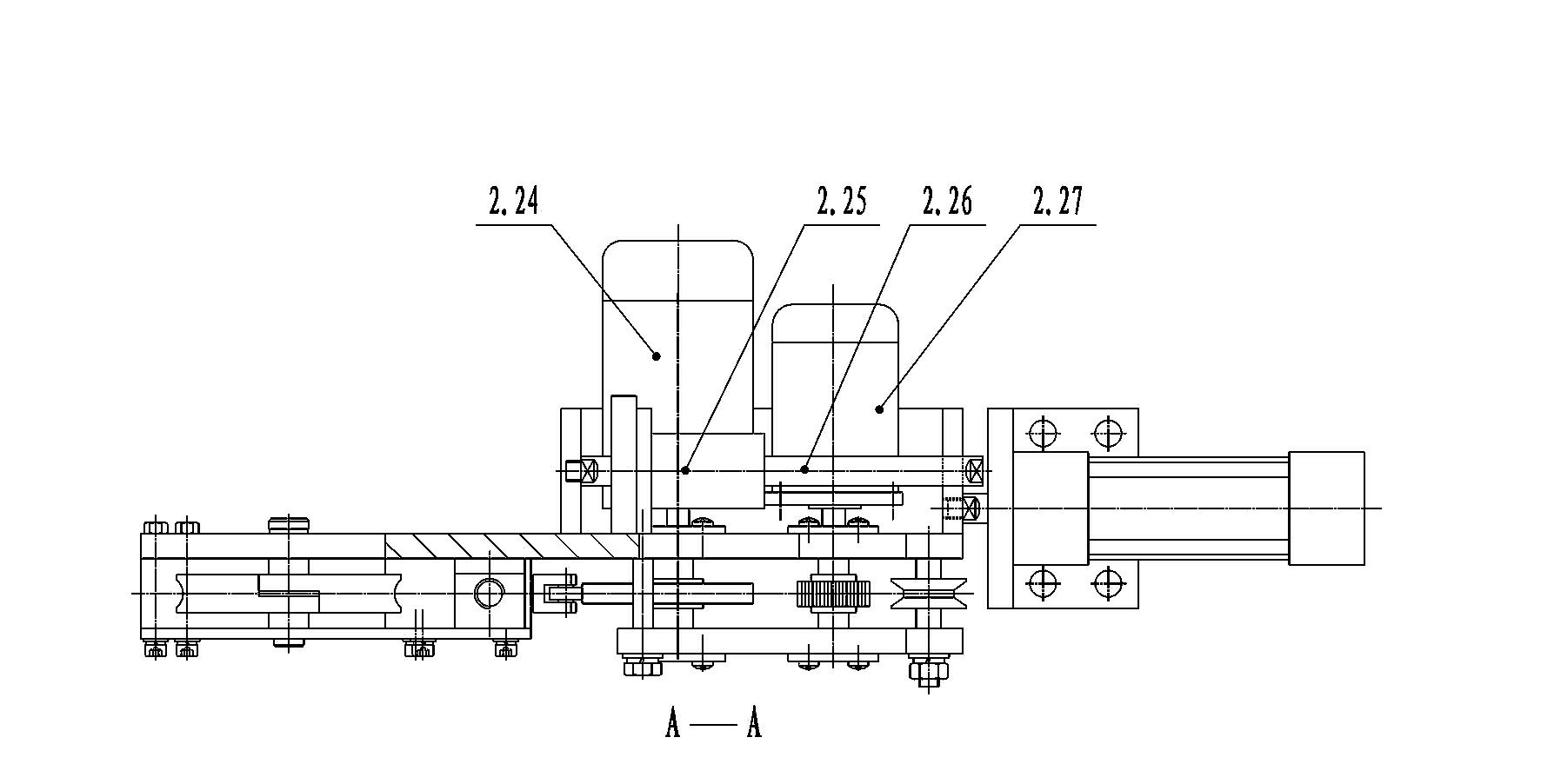

[0022] Such as figure 1 As shown, a plastic detonating tube automatic segmented packaging machine, including a frame 1 and a strapping system 2 installed on the upper part of the frame 1, a winding and retracting system 3, an ultrasonic heat sealing system 4, a wire feeding mechanism 5, a gauge Meter mechanism 6, wire pulley 7, and reel spindle 8 installed at the bottom of frame 1; the binding system 2 is installed above the winding and retracting system 3, ultrasonic heat sealing system 4, wire feeding mechanism 5, meter counting mechanism 6 The installation center is located on the same plane, and the guide wheel 7 is installed below the meter meter mechanism 6; Mechanism 6, wire feeding mechanism 5, and ultrasonic heat-sealing system 4 are sent to the winding and retracting system 3. The winding and retracting system 3 winds the handle first according to the design requirements, and after the winding is completed, the strapping system 2 performs binding. 4. Label and seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com