Nonel tube automatic bander

A detonating tube and baler technology, which is applied in fuse manufacturing and other directions, can solve the problems of high labor intensity, low efficiency and weak knotting, and achieve the effect of improving labor productivity, reducing labor intensity and facilitating knotting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

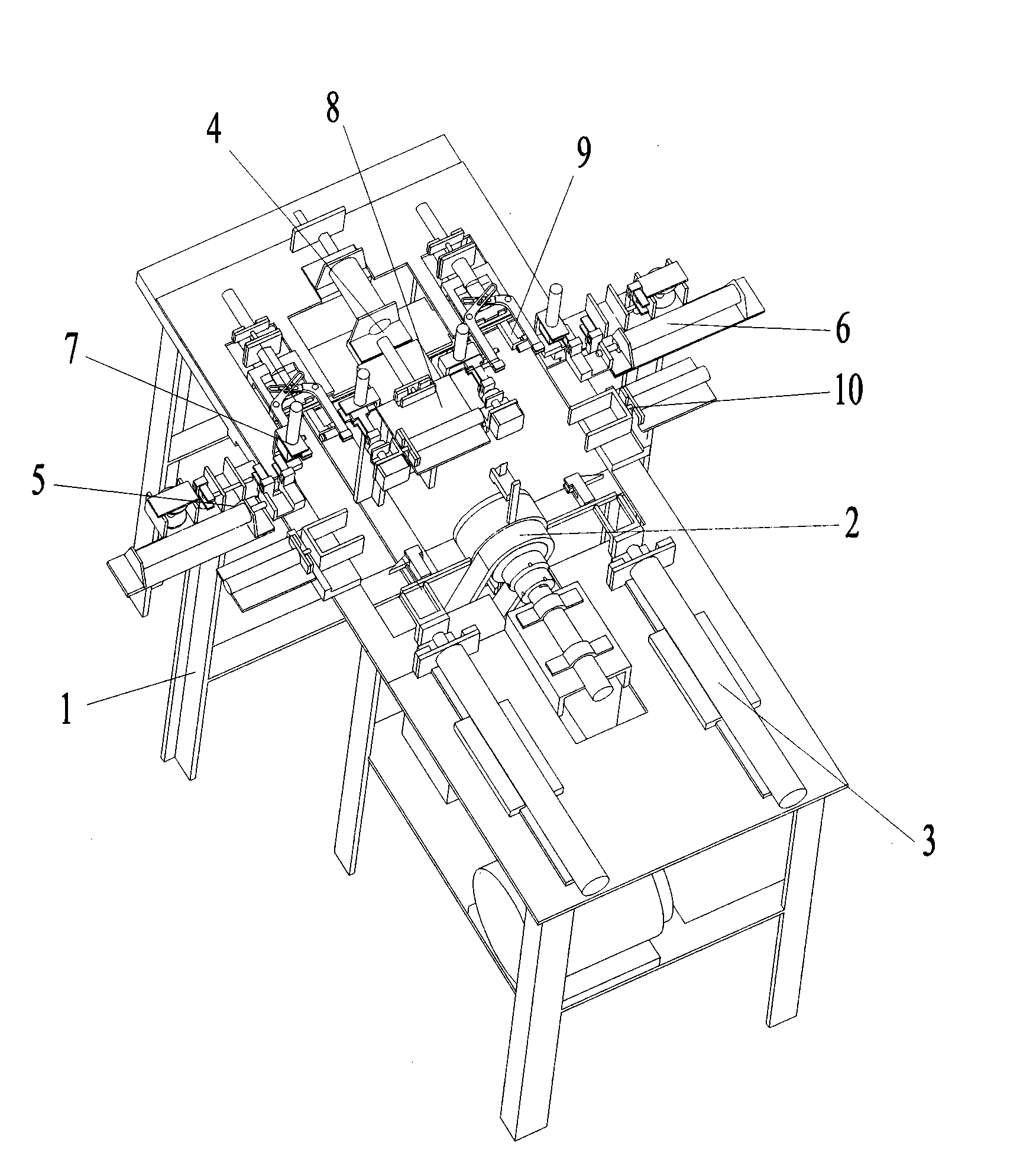

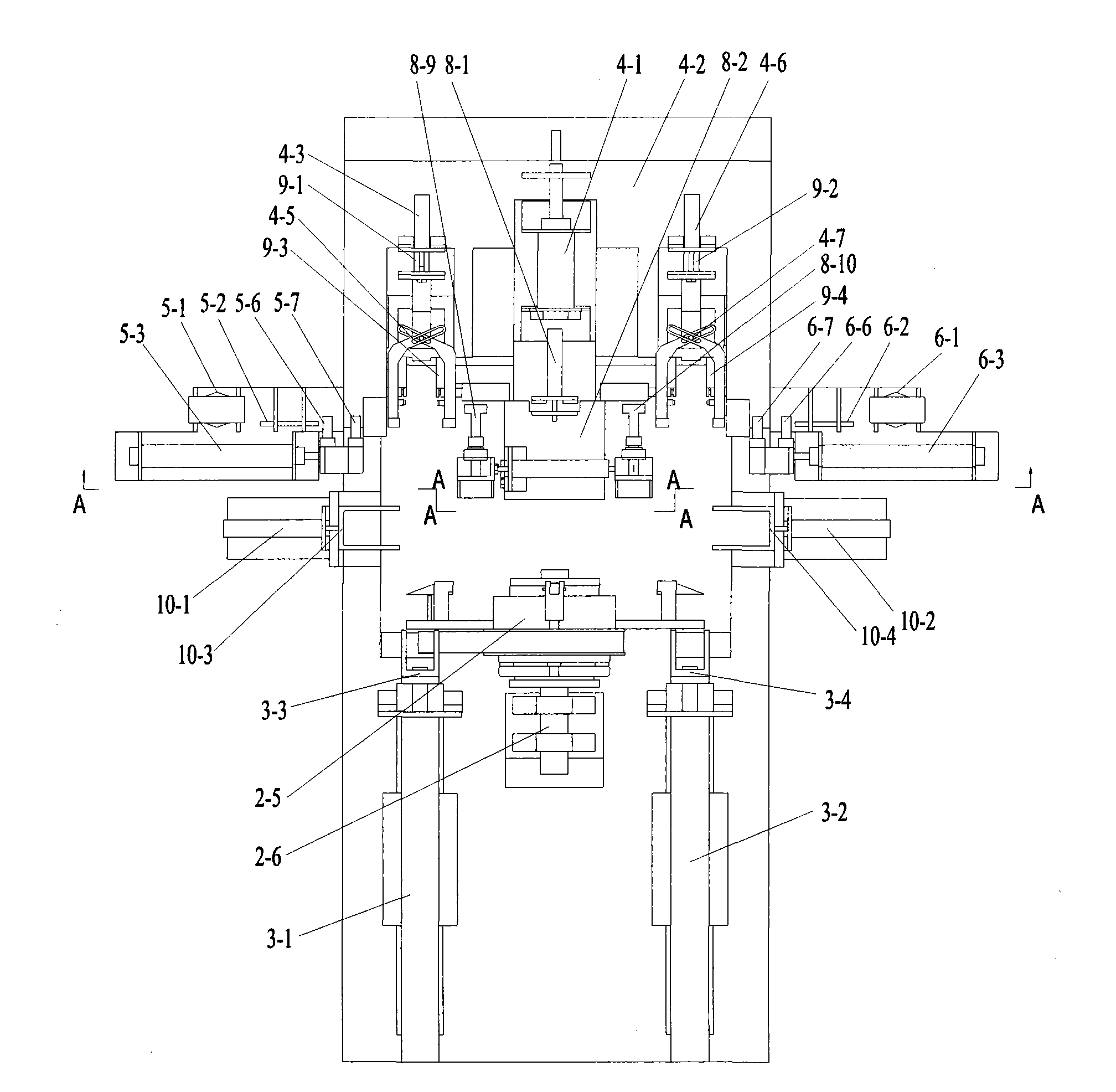

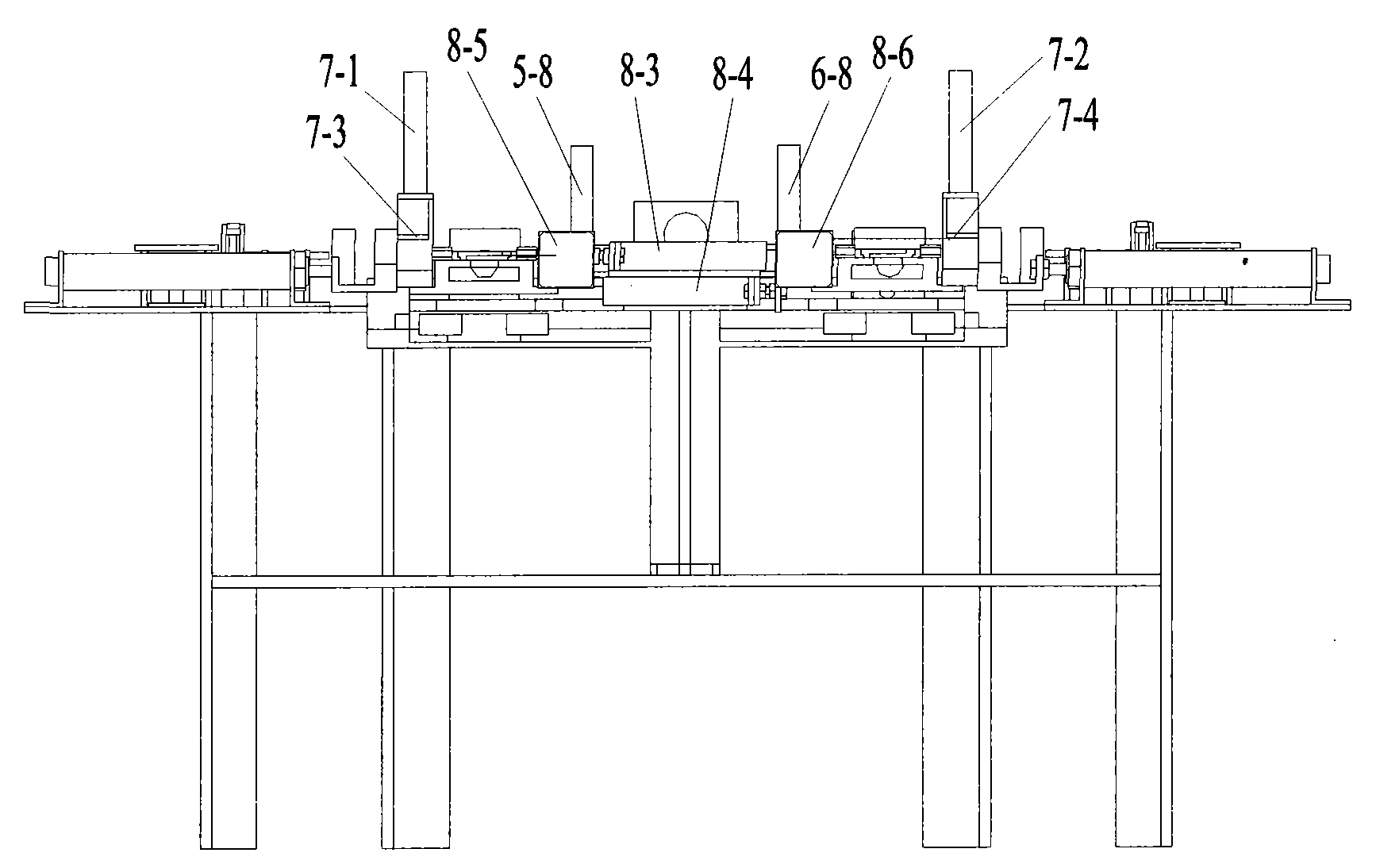

[0033] The plastic nonel automatic bundling machine of the present invention comprises a frame 1, a winding part 2, a pushing part 3, a clamping part 4, wire feeding parts 5 and 6, a cutting part 7, a knotting part 8, and a discharging part 9 , Auxiliary unloading part 10.

[0034] The winding part 2 is mainly composed of a motor 2-1, a V-belt 2-2, a clutch brake reducer 2-3, a synchronous belt 2-4, a winding wheel 2-5, and a shaft 2-6. Motor 2-1, clutch brake reducer 2-3, axle 2-6 are all fixed on the frame 1, and winding wheel 2-5 is installed on axle 2-6 front end, can rotate on axle 2-6. The motor 2-1 drives the clutch brake reducer 2-3 to work through the V belt 2-2, and the clutch brake reducer 2-3 drives the winding wheel 2-5 to rotate on the shaft 2-6 through the synchronous belt 2-4.

[0035] Feeding part 3 is made up of feeding cylinder 3-1,3-2, feeding folder 3-3,3-4. Feeding cylinders 3-1, 3-2 are symmetrically fixed on both sides of shaft 2-6 on frame 1, and fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com