Explosive-proof powder-dust-preventing powder conveying mechanism for automatic metal cord powder loading

A drug delivery and explosion-proof technology, which is applied in the manufacture of fuses, etc., can solve the problems of failure to realize the safety of drugs, the failure to realize the automation of drugs, and the failure to realize the effective explosion-proof of drugs, so as to improve intrinsic safety and safety Sexuality and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

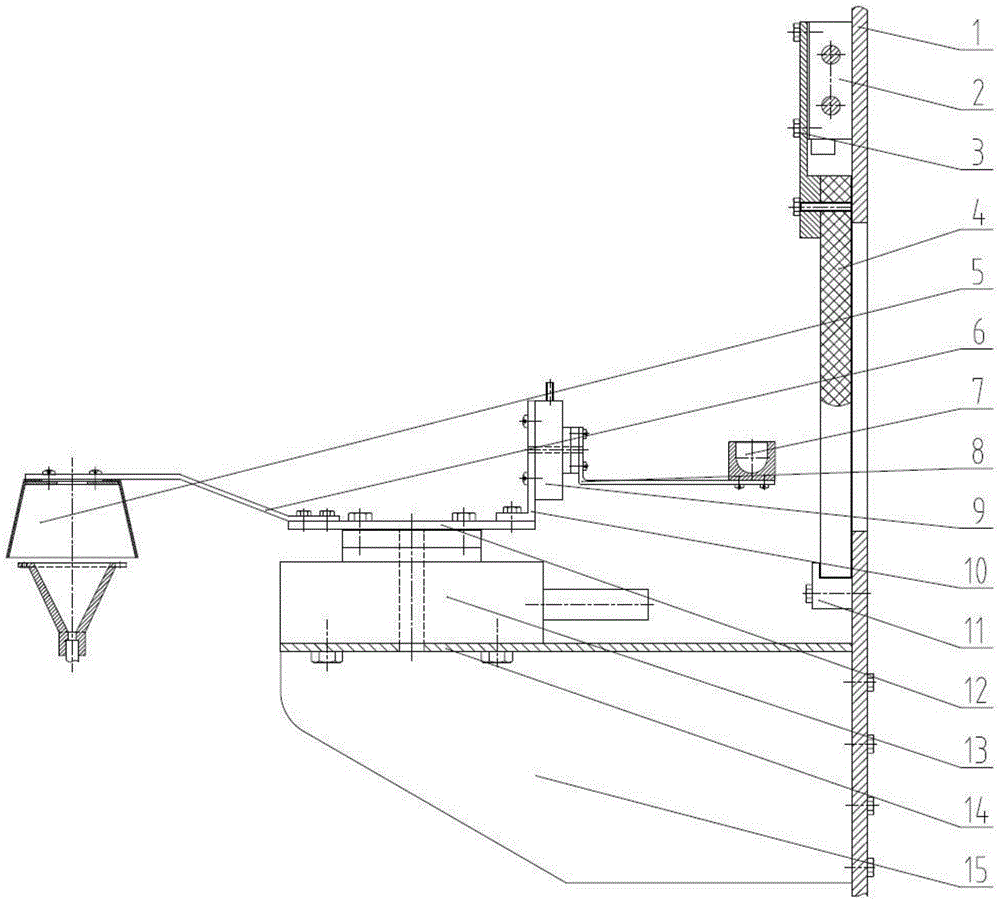

[0010] The invention comprises a flameproof steel plate 1, a protective plate sliding table cylinder 2, a protective plate connecting plate 3, a protective plate 4, a dust cover 5, a dust cover fixing frame 6, a medicine cup 7, a medicine cup bracket 8, and a medicine feeding rotary cylinder 9 , medicine feeding rotary cylinder support 10, protective plate guide bar 11, medicine delivery rotary cylinder cover plate 12, medicine delivery rotary cylinder 13, medicine delivery rotary cylinder mounting plate 14, medicine delivery rotary cylinder mounting plate support 15.

[0011] The relationship and function of each part are as follows: the medicine cup 7 is fixed to the medicine cup bracket 8 by screws; the medicine cup bracket is fixed to the medicine feeding rotary cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com