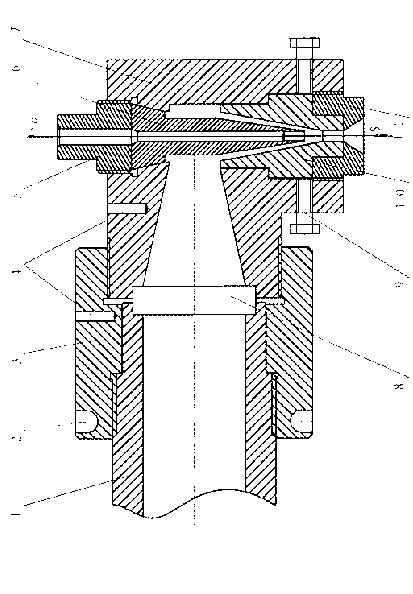

Adjustable nose for plastic detonating cord plastic coating and extruding machine

A technology of extruder head and extruder, which is applied in the manufacture of fuses, etc., to achieve the effects of high production efficiency, compact structure, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described by using the accompanying drawings and examples.

[0009] When assembling the adjustable head of the plastic detonating cord plastic-coated extruder of the present invention, first assemble the end with the annular arc groove on the outer circumference of the extruder head connecting sleeve 3 with the electric heating ring 2, and then assemble the The internal thread at this end is fixedly connected with the external thread on the delivery rod 1 of the extruder, and the filter plate 8 is installed on the internal stop of the delivery end of the delivery rod 1 of the extruder, and then the internal thread at the other end of the extruder head connecting sleeve 3 It is connected with the external thread of the input end on the left side of the extruder mold body 7; in the coaxial four-step hole and a tapered hole made by the extruder mold body 7 from the upper top surface through the lower bottom surface, first from the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com