Compound type decorating thermal insulation panel with cement polymer at double surfaces and preparation method thereof

A polymer and thermal insulation board technology, applied in chemical instruments and methods, hydraulic material layered products, building structures, etc., can solve the problem of not being affected by weather, achieve quality assurance, reduce cost, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 (full side upper limit example):

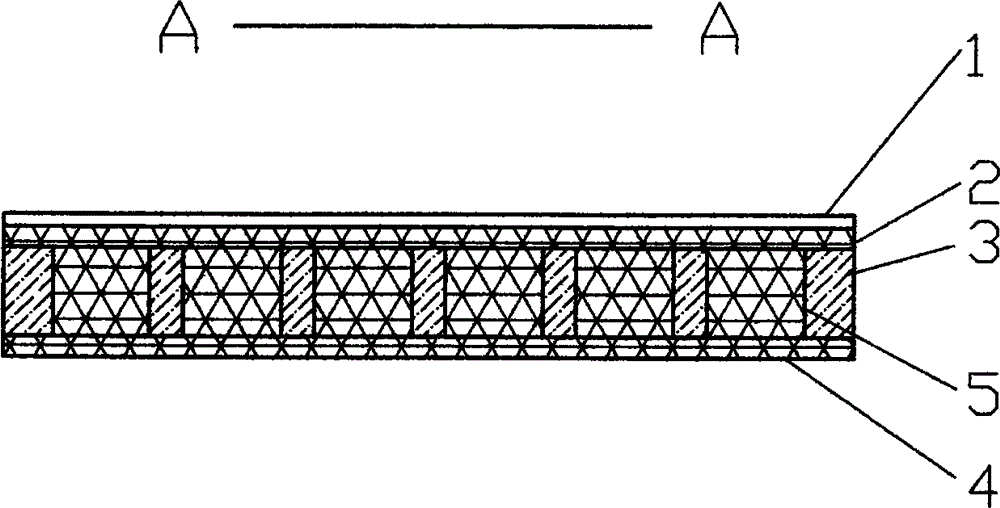

[0063] This example makes iron red imitation aluminum-plastic flat insulation board, and it comprises surface layer 2, the cover layer 1 that is coated on the surface layer 2 surface, bottom layer 4, the heat insulation layer 3 that is sandwiched between surface layer 2 and bottom layer 4, The surface layer 2 and the bottom layer 4 are connected together by connecting columns 5 . The preparation method is that the surface layer and the bottom layer are mixed firstly, and then formed in a mould.

[0064] Materials for surface layer 2: 80 kg of rapid hardening Portland cement, 100 kg of quartz powder, 50 kg of acrylic elastic emulsion, 2 kg of wetting and dispersing agent, 1 kg of defoamer, 5 kg of ethylene glycol, silicone waterproof 5 kg of agent, 1 kg of lignin, 20 kg of iron oxide red powder.

[0065] Materials for making the bottom layer 4 and connecting column 5: 80 kg of 42.5 cement, 100 kg of river sand, 2 kg of po...

Embodiment 2

[0075] Embodiment 2 (full square lower limit example):

[0076] This example makes yellow cultural stone-shaped insulation board, which includes surface layer 2, overcoat layer 1 coated on surface layer 2, bottom layer 4, heat insulation layer 3 sandwiched between surface layer 2 and bottom layer 4, surface layer 2 and the bottom layer 4 are connected together by connecting columns 5 . The preparation method is that the surface layer and the bottom layer are mixed firstly, and then formed in a mould.

[0077] Materials for making surface layer 2 and connecting column 5: 30 kilograms of rapid hardening yellow cement, 40 kilograms of wollastonite powder, 10 kilograms of acrylic elastic emulsion, 0.1 kilogram of wetting and dispersing agent, 0.1 kilogram of defoaming agent, 1 kilogram of ethylene glycol, 1 kg of silicone waterproofing agent, 0.1 kg of lignin,

[0078] The material for making the bottom layer 4: 30 kilograms of rapid hardening Portland cement, 40 kilograms of st...

Embodiment 3

[0089] Embodiment 3 (principal preferred example)

[0090] In this example, imitation granite insulation board is made, which includes surface layer 2, overcoat layer 1 coated on surface layer 2, bottom layer 4, heat insulation layer 3 sandwiched between surface layer 2 and bottom layer 4, and surface layer 2 and the bottom layer 4 are connected together by connecting columns 5 . The preparation method is that the surface layer and the bottom layer are mixed firstly, and then formed in a mould.

[0091] Materials for surface layer 2: 50 kg of sulphoaluminate cement, 20 kg of mica powder, 40 kg of quartz powder, and 30 kg of epoxy resin emulsion.

[0092] Materials for the bottom layer 4 and connecting column 5: 60 kg of 52.5 Portland cement, 20 kg of heavy calcium, and 40 kg of stone powder.

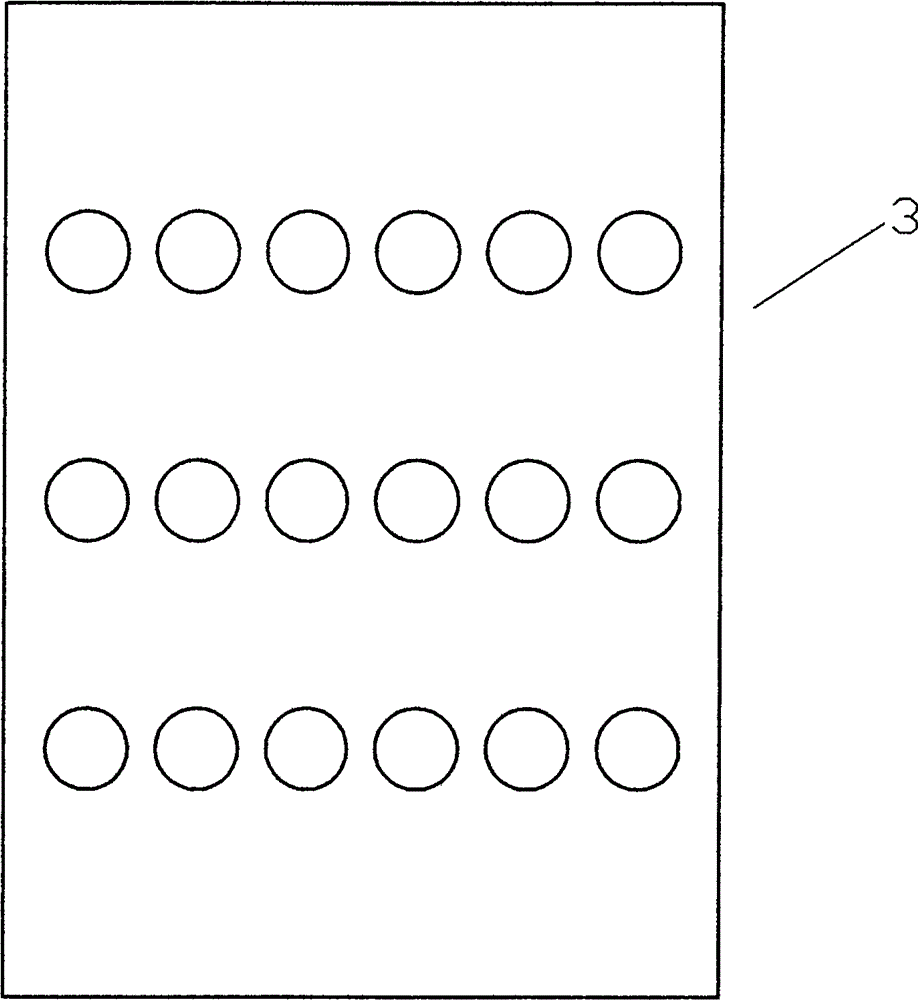

[0093] The insulation layer 3 is a rock wool board.

[0094] The overcoat layer 1 uses imitation granite paint as primer, and the overcoat with fluorocarbon varnish.

[0095] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com