Thin plaster, plaster thinning making method and apparatus

A technology of black plaster and preparation method, which is applied in the direction of ointment delivery, making medicine into a special physical or taking form device, emulsion delivery, etc. It can solve the problem of uniform spreading of plaster layers, fast release speed, and obstruction of sweat excretion, etc. problems, to avoid affecting health, improve production efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

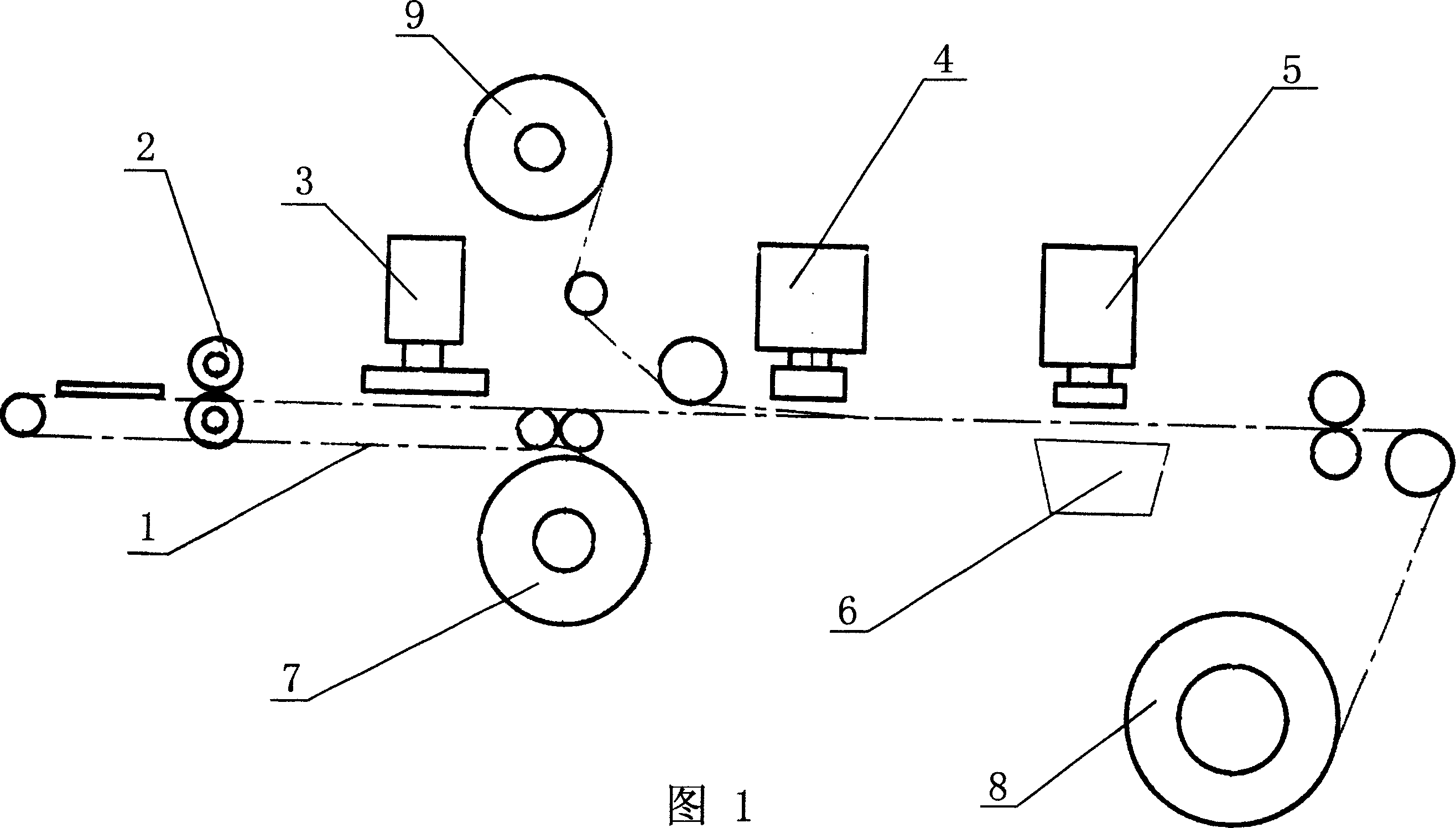

[0018] The black plaster of the present invention is prepared using the black plaster molding machine shown in Fig. 1:

[0019] 1) Take a moderately old and deodorized paste and place it on the backing material 1 of the black plaster thinning equipment shown in Figure 1, and then the paste is transferred to the temperature-controlled tableting device 2 at the front end of the backing material 1 , And heated and pressed into a sheet by the temperature control tablet pressing device 2;

[0020] 2) The paste compressed into a sheet is conveyed to the blank forming device 3 by the backing material 1 and punched by the blank forming device 3 into a paste blank of uniform size and uniform thickness;

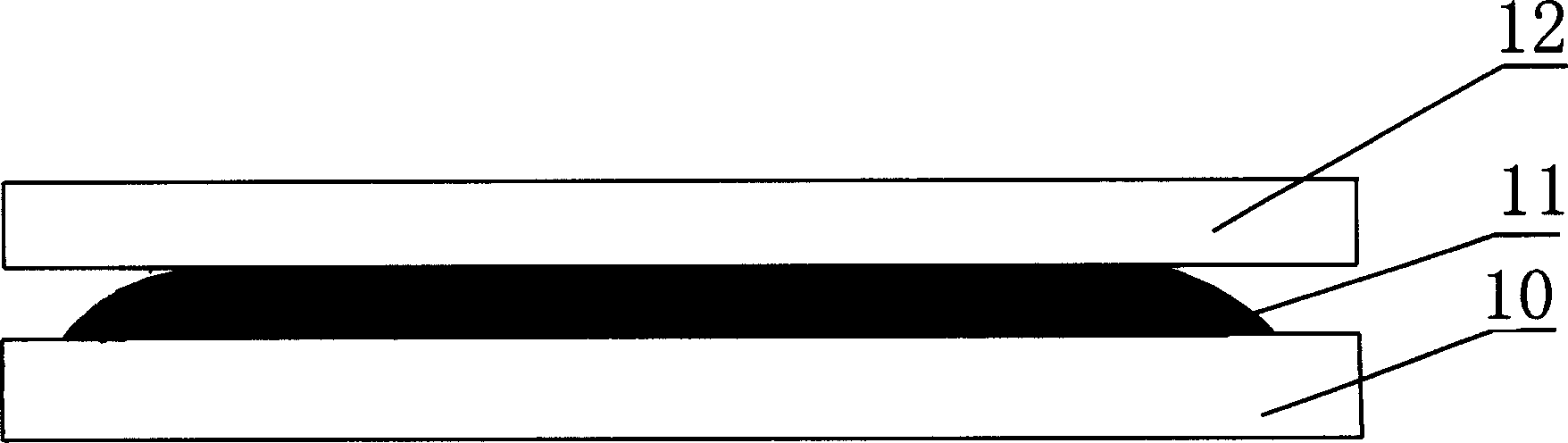

[0021] 3) Cover the plaster blank with the film so that the plaster blank is between the backing material and the cover, and then heat and stamp through the thinning device 4 to obtain a plaster layer thickness of 0.9 mm;

[0022] 4) The resulting round flake-shaped black plaster is transf...

Embodiment 2

[0024] 1) Take a moderately old and deodorized paste and place it on the backing material 1 of the black plaster thinning equipment shown in Figure 1, and then the paste is transferred to the temperature-controlled tableting device 2 at the front end of the backing material 1 , And heated and pressed into a sheet by the temperature control tablet pressing device 2;

[0025] 2) The paste compressed into a sheet is conveyed to the blank forming device 3 by the backing material 1 and punched by the blank forming device 3 into a paste blank of uniform size and uniform thickness;

[0026] 3) Cover the plaster blank with the film so that the plaster blank is between the backing material and the cover, and then heat and stamp through the thinning device 4 to obtain a plaster layer with a thickness of 0.1 mm;

[0027] 4) The resulting round flake-shaped black plaster is transferred to the punching and shearing device 5 for shearing. The cut black plaster drops to the falling hopper 6 belo...

Embodiment 3

[0029] 1) Take a moderately old and deodorized paste and place it on the backing material 1 of the black plaster thinning equipment shown in Figure 1, and then the paste is transferred to the temperature-controlled tableting device 2 at the front end of the backing material 1 , And heated and pressed into a sheet by the temperature control tablet pressing device 2;

[0030] 2) The paste compressed into a sheet is conveyed to the blank forming device 3 by the backing material 1 and punched by the blank forming device 3 into a paste blank of uniform size and uniform thickness;

[0031] 3) Cover the plaster blank with the film so that the plaster blank is between the backing material and the cover, and then heat and stamp through the thinning device 4 to obtain a plaster layer thickness of 0.3 mm;

[0032] 4) The resulting round flake-shaped black plaster is transferred to the punching and shearing device 5 for shearing. The cut black plaster drops to the falling hopper 6 below the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com