Telescopic steel frame joint suitable for large tunnel deformation

A large deformation, steel frame technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as reducing the initial support bearing capacity, large safety risks, and inability to effectively control the range of expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the structure of the present invention will be further described in detail in conjunction with the drawings and embodiments.

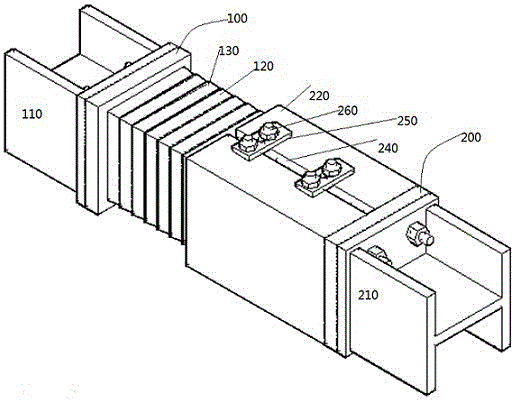

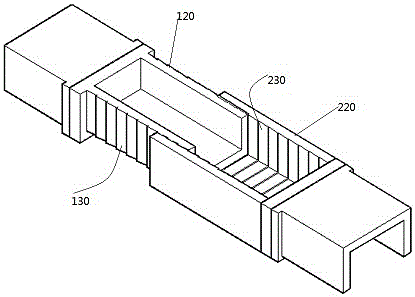

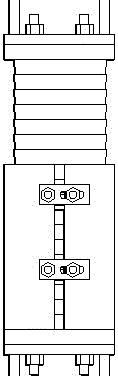

[0015] Depend on Figure 1 ~ Figure 3 It can be seen that the telescopic steel frame joint suitable for the large deformation of the tunnel in the present invention is composed of two coupled parts, the upper part 100 and the lower part 200. Both the upper part 100 and the lower part 200 have a joint for connecting with the steel frame, that is, the upper joint 110 and the lower coupling head 210; the upper part 100 has a convex body end 120, and the outer surface of the convex body end has a barb-shaped barb 130; the lower part 200 has a fitting cavity 220 that can fit with the upper convex body end 120, and the fitting cavity The inner surface also has barb-shaped reverse barbed teeth 230; the fitting cavity 220 is provided with a slit 240; the connecting steel plate 250 spans both sides of the slit and is connected with the fitting cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com