Launch canister based on carbon fiber composite base material and manufacturing method

A launch tube, carbon fiber technology, applied in the direction of launch devices, etc., can solve the problems of discontinuous manufacturing and material properties, cumbersome process implementation, low production efficiency, etc., to achieve good interface continuity, strong process operability, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

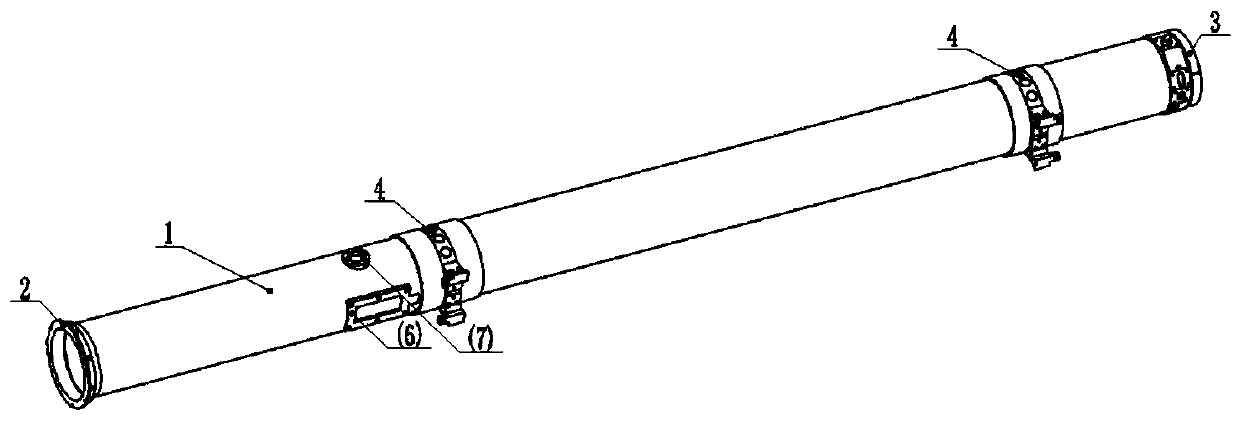

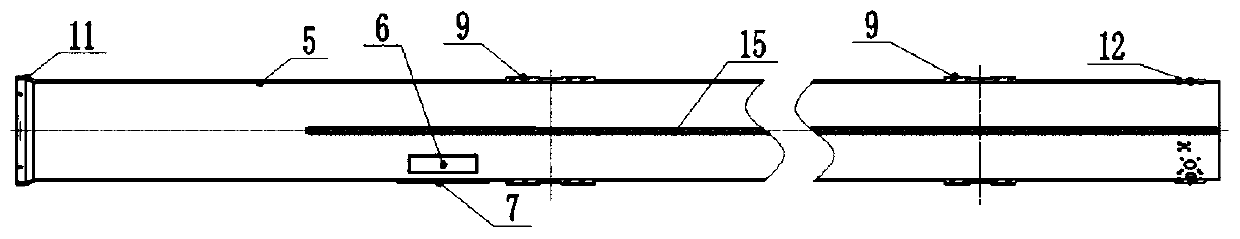

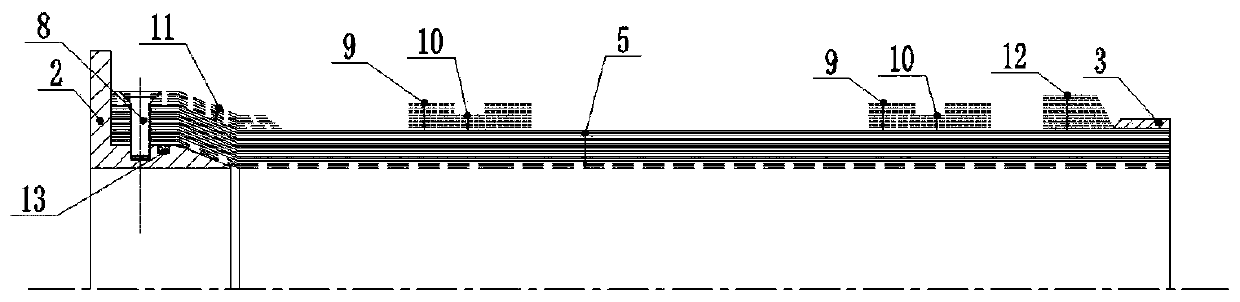

[0033] Example 1, such as Figure 1-6 The launch tube designed and manufactured by the present invention shown has a main structure launch tube 1 comprising an ablation-resistant prepreg layer 14, an ablation-resistant layer 16, a first flame-retardant and toughened layer 17, and a second Two flame retardant and toughening layers 18 , between the ablation-resistant prepreg layer 14 and the ablation-resistant layer 16 , there is also a guide plate 15 laid along the length direction of the emitting cylinder 1 .

[0034] The ablation-resistant prepreg layer 14 is a phenolic resin prepreg layer, and the ablation-resistant layer 16, the first flame-retardant and toughened layer 17 and the second flame-retardant and toughened layer 18 are made by adopting carbon fiber wet winding method Manufactured, the ablation-resistant layer 16 and the first flame-retardant and toughened layer 17 are spirally wound at an angle of ±23°, and the inside of the second flame-resistant and toughened l...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that the helical winding angle of the cylinder is increased, thereby reducing the thickness ratio of the helical winding, the weight remains unchanged, the strength of the cylinder is enhanced, and the ability to resist internal pressure is increased.

[0061] A method for making a launch tube, comprising the steps of:

[0062] Step 1: Use the TF1726 / HFW196PA-D6 / 50 phenolic prepreg of Jiangsu Hengshen Co., Ltd. as the ablation-resistant prepreg layer 14 located in the innermost layer of the cylinder. After pre-compaction, use phenolic prepreg TF1726 / HFW196PA-D6 / 50 to lay out the guide plate 15 along the length direction of the barrel. After that, the ablation-resistant layer 16 of the cylinder is formed by carbon fiber wet winding technology. The resin is selected from the TF1726 phenolic resin of Jiangsu Hengshen Co., Ltd., and the carbon fiber is selected from the HF30S type (equivalent to Toray T700S) fiber o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com