Polyethylene fabric composite concrete guniting pipe

A polyethylene and concrete technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as short service life, high price, and increased cost of reinforcement layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

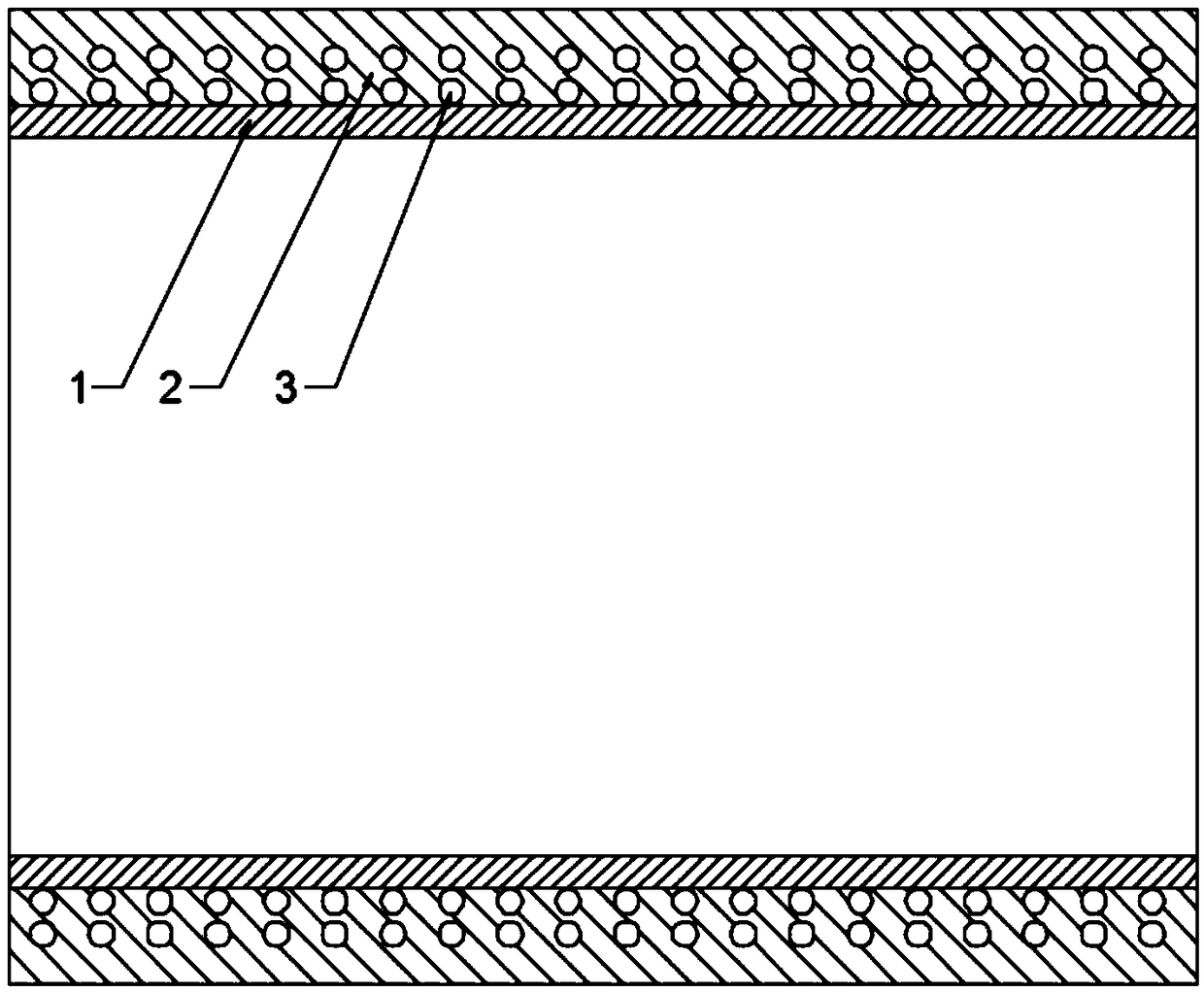

[0017] Embodiment 1; (as figure 1 shown)

[0018] The polyethylene fabric composite concrete spraying pipe includes a pipe body and a wear-resistant layer 1 located on the inner wall of the pipe. The pipe body 2 is compounded with at least two layers of reinforced fiber fabric winding layers 3, and the winding direction of the adjacent reinforcing fiber fabric winding layers 3 On the contrary; the wear-resistant layer 1 is made of materials with good wear resistance, which can be made of polyethylene modified materials, polyethylene nanomaterials, and wear-resistant rubber. One or more materials can be mixed in any proportion, or can be made of The main function of the wear-resistant layer 1 is to resist the wear of the solid-liquid mixture on the pipe wall when the concrete is conveyed. First, put the wear-resistant material mixture into the plastic extruder to heat and plasticize, and then continuously extrude through the inner extrusion die of the spray tube to form a tube...

Embodiment 2

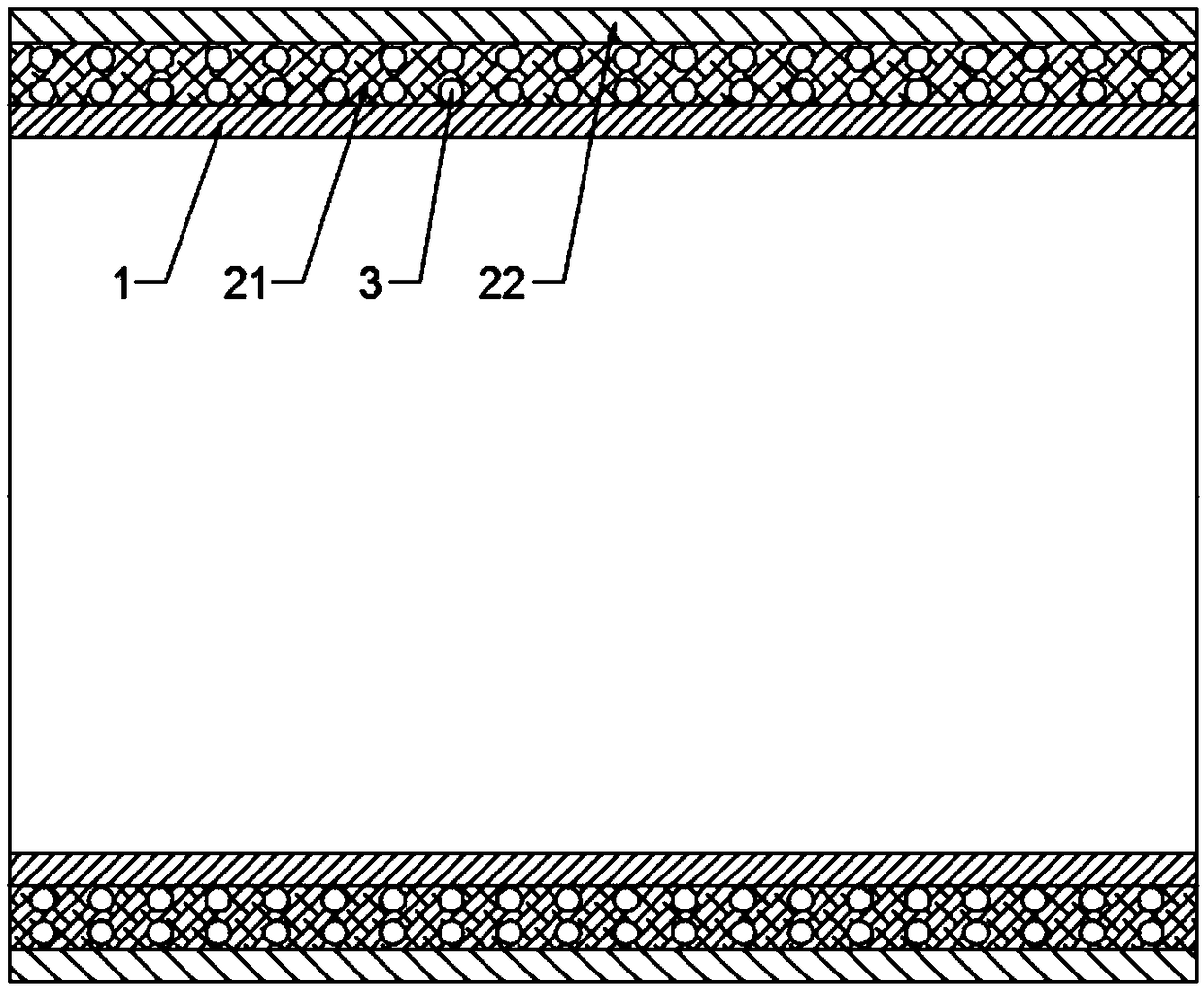

[0019] Embodiment 2: (as figure 2 shown)

[0020] The basic structure and principle of this embodiment are the same as the product shown in Embodiment 1, and figure 1 The structural difference of the sprayed pipe shown is that the pipe body 2 includes a hot melt adhesive layer 21 and a protective layer 22 , the protective layer 22 is made of common polyethylene material, and the reinforcing fiber fabric winding layer 3 is located in the hot melt adhesive layer 21 . figure 2 In the product shown, after the reinforced fiber fabric is wound on the surface of the wear-resistant layer 1 to form a winding net, the hot melt adhesive is extruded by a plastic extruder to fill the mesh of the mesh reinforcement structure to form a hot melt adhesive layer 21. Viscosity makes the wear-resistant layer 1 and the reinforced fiber fabric winding layer 3 bonded to form a more firm composite body, and the plastic of the protective layer 22 of the pipe body 2 is also bonded with the hot melt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com