Steel reinforced poly ethylene (PE) corrugated pipe and manufacturing equipment thereof

A corrugated pipe and equipment technology, which is applied in the field of equipment for manufacturing the PE corrugated pipe, can solve the problems of high power extrusion equipment, expensive processing equipment, and low yield, and achieve reduced energy consumption, low production cost, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

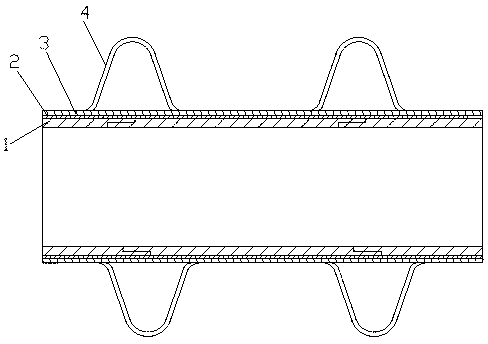

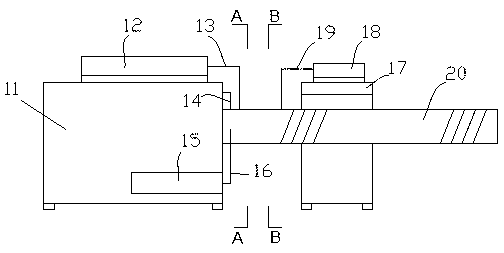

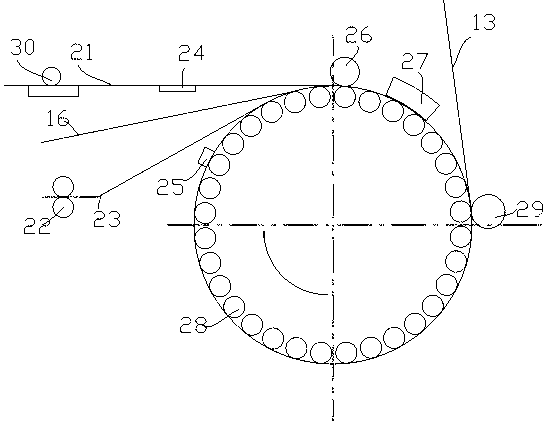

[0021] Specific embodiments of the present invention, such as figure 1 with figure 2 As shown, a steel-reinforced PE corrugated pipe includes a pipe inner wall spirally rolled by a plastic plate strip 1, a layer of steel mesh 2 is wrapped on the outside of the pipe inner wall 1, and a pipe wall polyethylene layer 3 is wrapped on the outside of the steel mesh. The belt 4 is fastened to the polyethylene layer 3 and the steel belt is covered with the polyethylene layer. According to the different requirements for the strength of the pipeline, it is also possible to wrap more layers of steel mesh on the outside of the inner wall of the pipeline, such as two or three layers and so on. In order to make the steel mesh and the steel strip fit better with the plastic and increase the corrosion resistance of the steel strip, the steel mesh and the steel strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com