Tube-framework strengthened plastic composite tube and producing process thereof

A technology of reinforced plastics and composite pipes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of limited pressure, low production efficiency, high product cost, etc., and achieve pressure-bearing capacity Improvement, production efficiency High and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

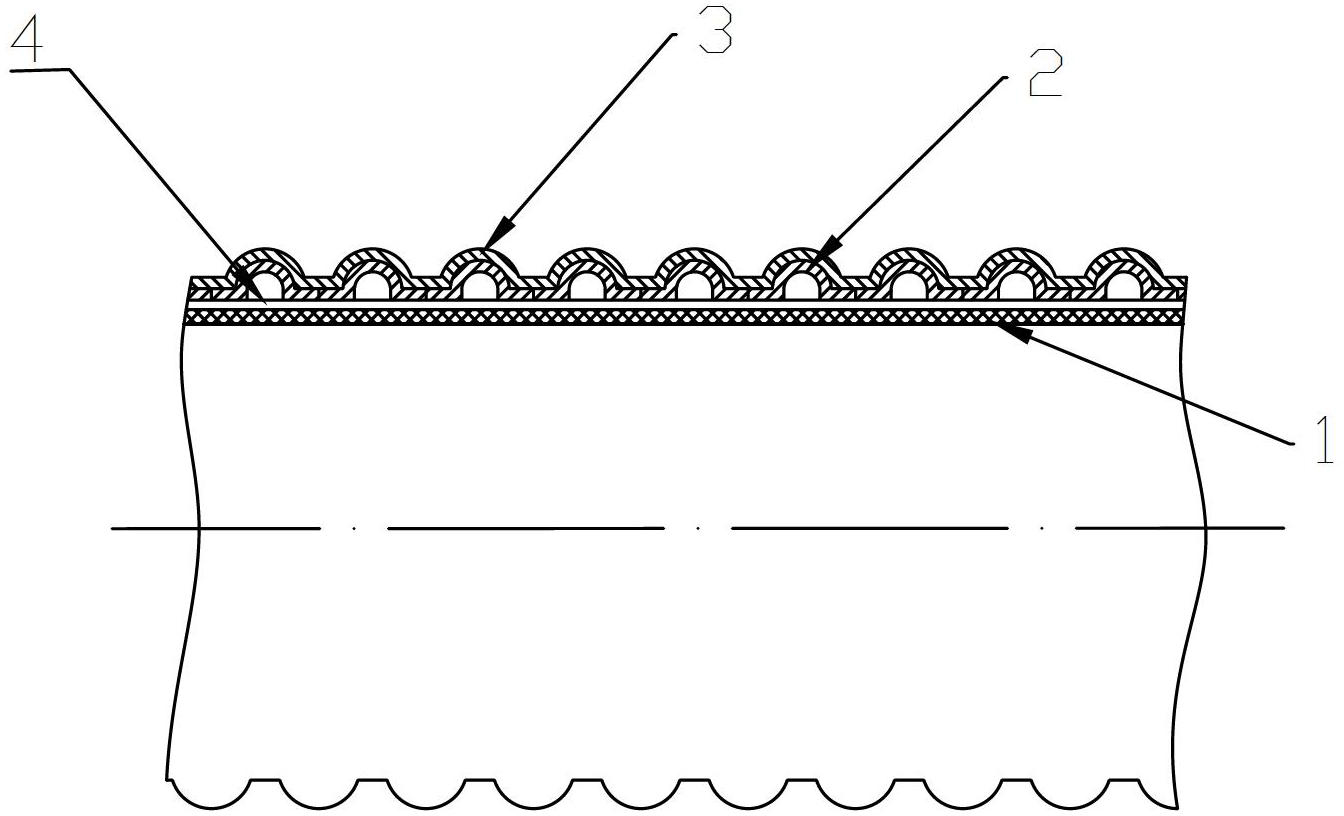

[0030] Such as figure 1 As shown, the winding structure wall 2 is a strip-shaped profile.

Embodiment 2

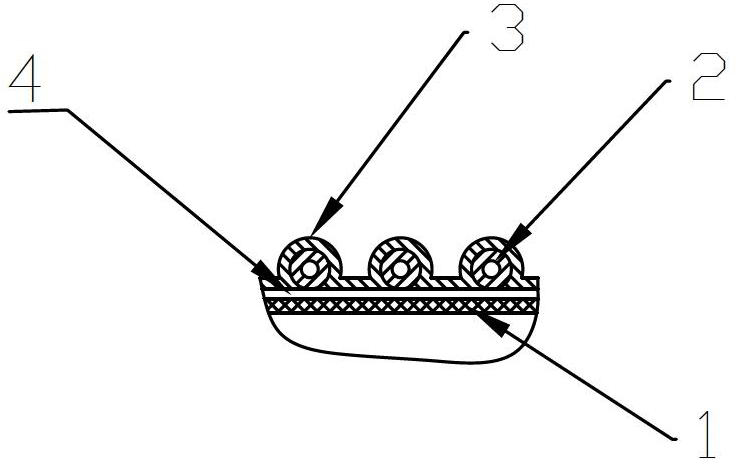

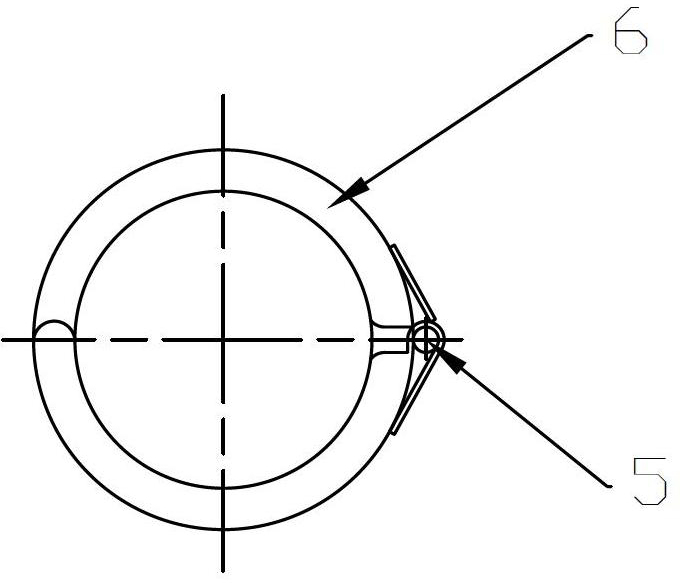

[0032] Such as figure 2 As shown, the winding structure wall 2 is a hollow tubular profile made of metal or non-metal.

[0033] Such as Figure 4 As shown, the production process of the pipe skeleton reinforced plastic composite pipe of the present invention is characterized in that it comprises the following steps:

[0034] ①The extruder extrudes the integrally formed thin-walled tube, which is vacuum shaped and cooled to form the internal pressure tube 1;

[0035] ② Use a mold to support the tube body of the internal pressure tube 1 into a circle, and its out-of-roundness is controlled within 1.5%, and a layer of reinforcing mesh or reinforcing wire coated with glue inside and outside is wound on the outer surface of the internal pressure tube 1;

[0036] ③The winding structure wall 2 is spirally wound on the outside of the reinforcement mesh or reinforcement wire according to a certain pitch;

[0037] ④ extruder extruding plastic material in molten state, the plastic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com