Prestressed rail beam and its manufacture

A manufacturing method, technology of track beams, applied in the field of running tracks of rail vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

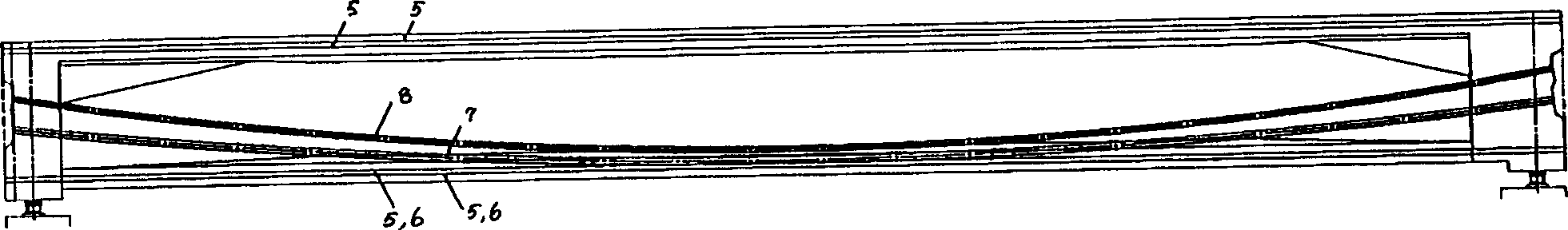

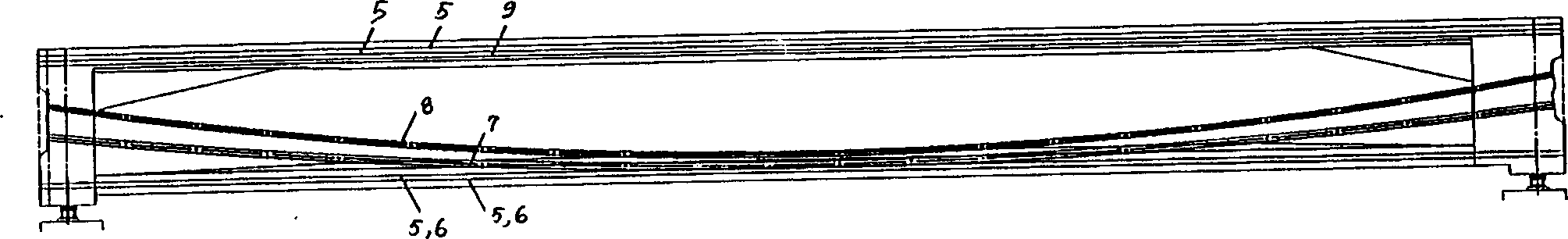

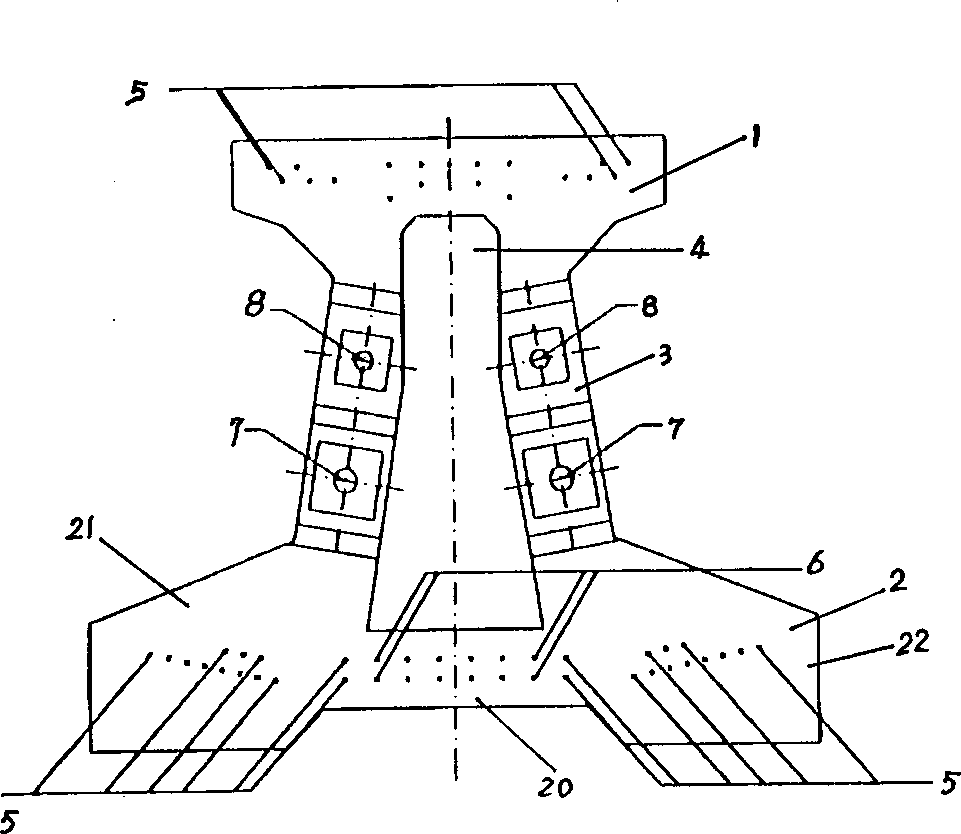

[0040] see figure 1 , figure 2 and image 3 , the prestressed track beam of the present invention comprises a beam top plate 1, a beam bottom plate 2, and a beam web 3, and is characterized in that: a number of beams are arranged in the track beam top plate 1 and the left part 21 and the right part 22 of the beam bottom plate 2. Eccentric pretensioning method prestressing beams 5, a number of eccentric pretensioning method prestressing beams 6 are arranged in the middle part 20 of the track beam bottom plate 2; a first posttensioning method is respectively arranged on the two webs 3 of the track beam according to the quadratic parabola shape The prestressing beams 7 are each configured with a second post-tensioning prestressing beam 8 in the shape of a quadratic parabola.

[0041] For curved track beams, in addition to the prestressed beams configured as described above, transverse eccentric pretensioned prestressed beams 9 should also be arranged in the top and bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com