Ultra-low carbon steel, and preparation method and application thereof

A technology of ultra-low carbon steel and chemical composition, which is applied in the field of ultra-low carbon steel wire production for copper-clad steel, and can solve the problems of poor comprehensive performance, high strength of steel wire, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

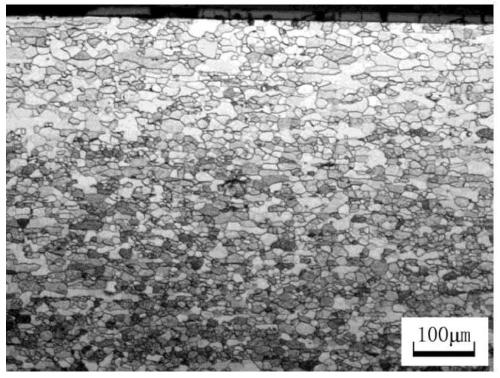

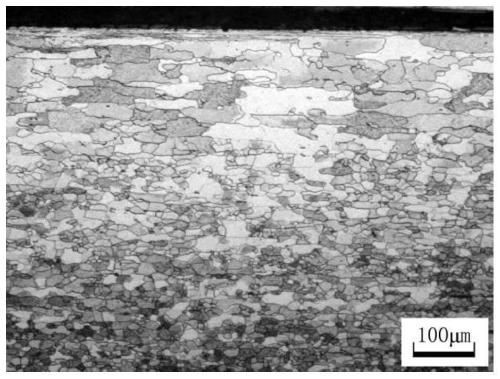

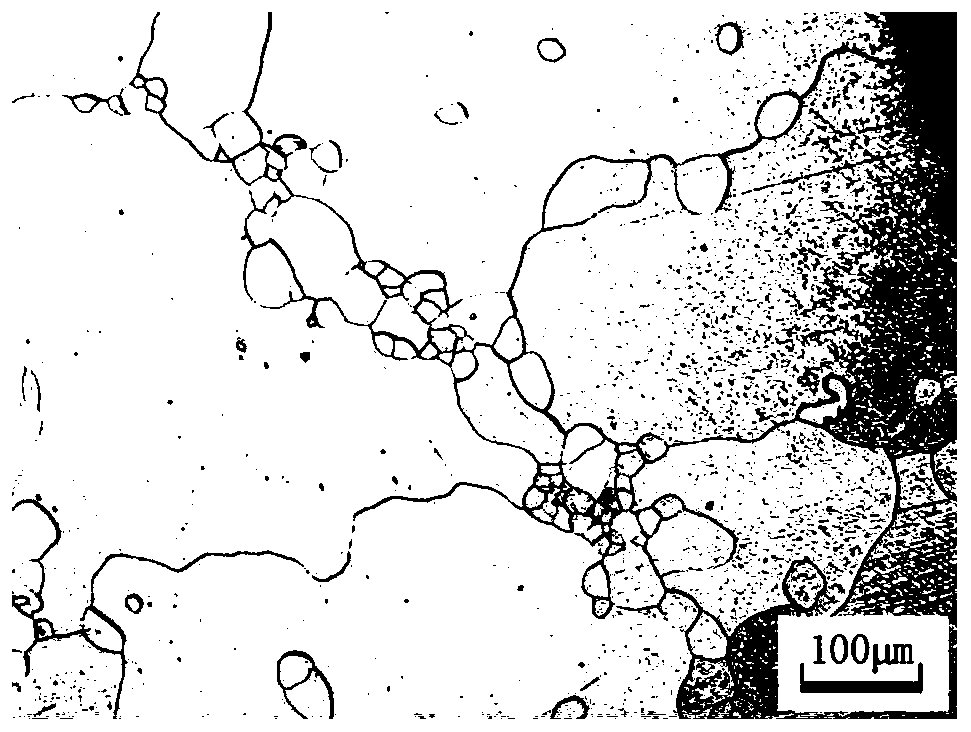

Image

Examples

Embodiment 1 to Embodiment 8

[0064] Embodiment 1 to embodiment 8 provide a kind of preparation method of low carbon steel wire, specifically as follows:

[0065] (1) Dry drawing: The hot-rolled wire rod with the chemical composition shown in Table 1 (the rest is Fe and unavoidable impurities) is mechanically descaled by a roller sheller, then phosphating and drying, and lubricated into Continuous wire drawing machine, after 5 times of continuous drawing and deformation into 2.5-3.0mm steel wire, the wire is collected and rolled. The total drawing deformation reduction rate is 80-90%, and the drawing reduction rate per pass is 26- 36%.

[0066] (2) Wet drawing: After dry drawing, the steel wire is phosphated and lubricated, and then drawn into the water tank for drawing, and drawn into 1.2-1.6mm filaments after 5 passes, and the total drawing deformation reduction rate is 70-80 %. The area reduction rate of each drawing is 20-30%.

[0067] (3) Recrystallization annealing: The coils drawn into filaments ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com