Deformation joint structure for light rail elevated station and construction method thereof

A construction method and deformation joint technology are applied in the field of deformation joint structure, which can solve the problems of fire prevention, waterproofing, moisture resistance and heat preservation, and achieve the effect of simple structure and construction technology, convenient construction, and protection of concrete structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the deformation joint structure for a light rail elevated station of the present invention will be described in detail with reference to the accompanying drawings and specific embodiments.

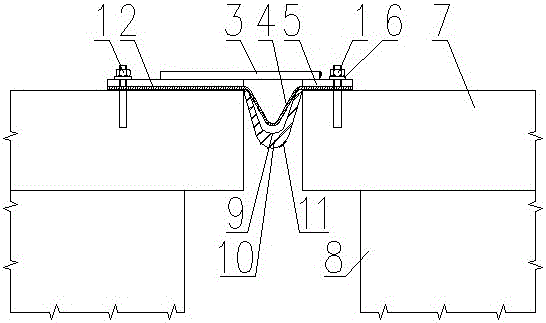

[0031] figure 1 It is a structural schematic diagram of the deformation joint structure used for the light rail elevated station of the present invention. like figure 1 As shown, the deformation joint structure for the light rail elevated station of the present invention is arranged between the floor plates 7 on both sides of the deformation joint. The deformation joint structure includes a water stop 4, a fire-stop plate and a plurality of stainless steel plates. By pressing the stainless steel plates, the fire-stop plate and the water stop 4 are fixed on the floor plates 7 on both sides by bolts 1 arranged at intervals. Floor slabs 7 are supported by support beams 8 . The spacing of the bolts 1 is not more than 350mm. A bolt washer 6 is provided below the bolt 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com