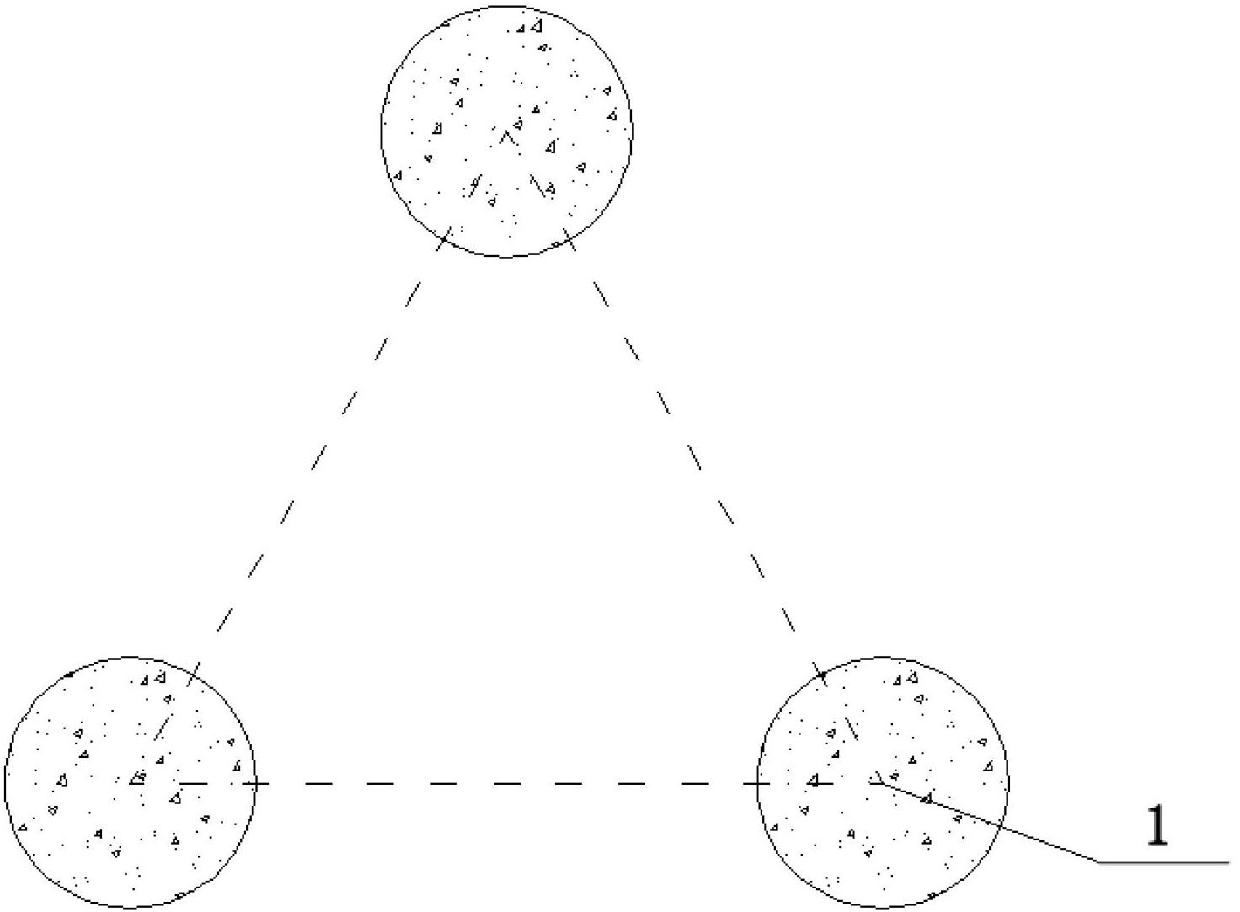

Reinforcement method for foundation of silt soft-based cast-in-place box girder support

A foundation reinforcement and silt technology, applied in foundation structure engineering, soil protection, sheet pile wall, etc., can solve the problems of long construction period, heavy workload and high cost, achieve simple and fast construction, save subsequent investment and safety risks small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

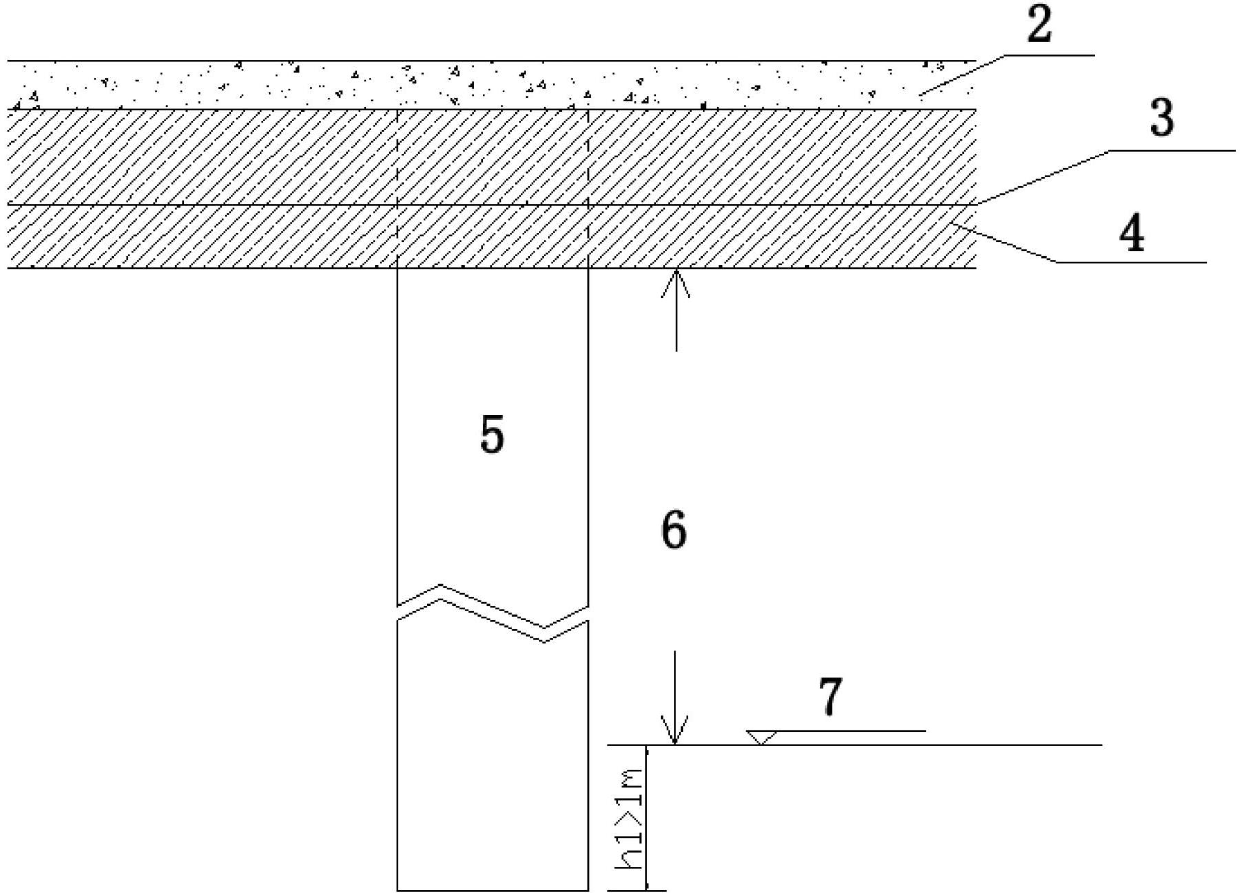

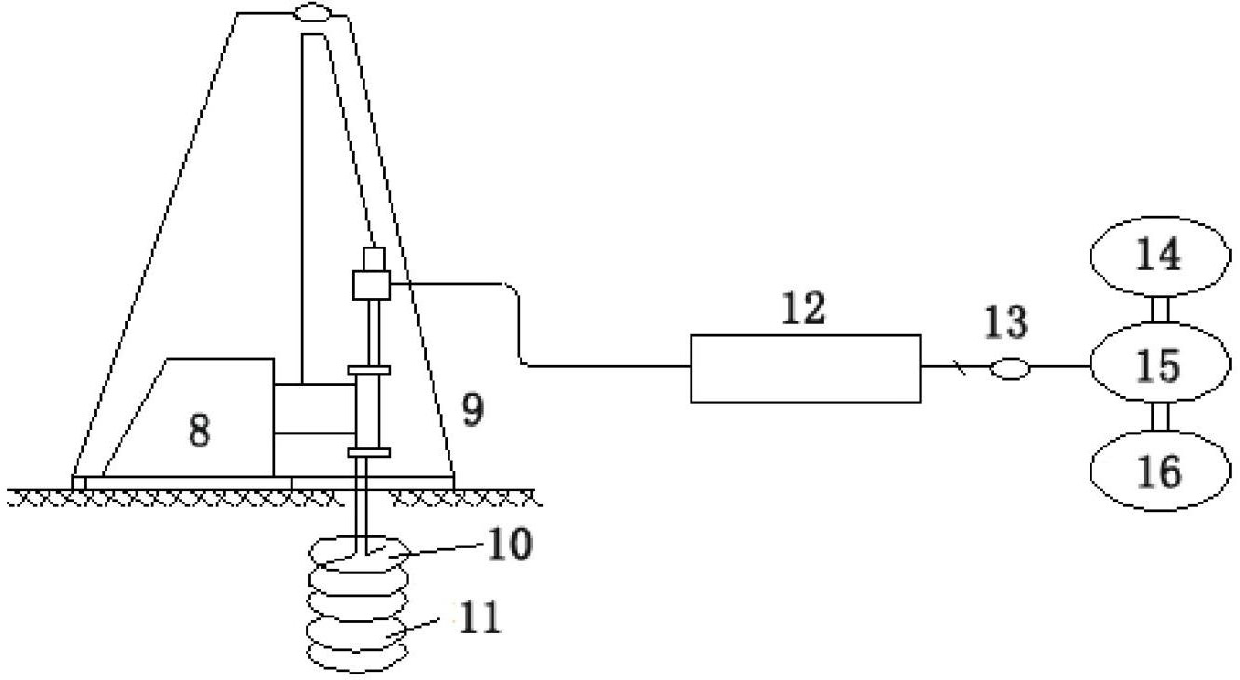

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing, and the principle of this method is very clear to those skilled in the art.

[0047] The present invention has a specific application embodiment, which is an interchange project. The main bridge of the interchange runs from east to west, spans the Haibin Avenue and the secondary seawall, and the east section of the secondary seawall is a land area that was pumped and filled in 2009. The 6m is pumped filling soil layer plus artificial miscellaneous filling soil, which has high porosity, high water content, small water permeability coefficient, and poor self-support. After the surface layer is exposed to the sun, it forms a closed dry and hard layer with a thickness of 30cm. The pore water in the underlying soil layer is not easy to evaporate. According to surface observation, the annual natural consolidation settlement is about 100mm. The bridge is the main road connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com