Supporting and retaining structure of existing retaining wall straight penetrated by large-span tunnel and construction method thereof

A technology of retaining structure and construction method, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of increasing sliding force, affecting the appearance, and limited tension of anchor cables, etc., and achieves reducing deformation and strengthening reinforcement Good effect and load-bearing capacity, reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

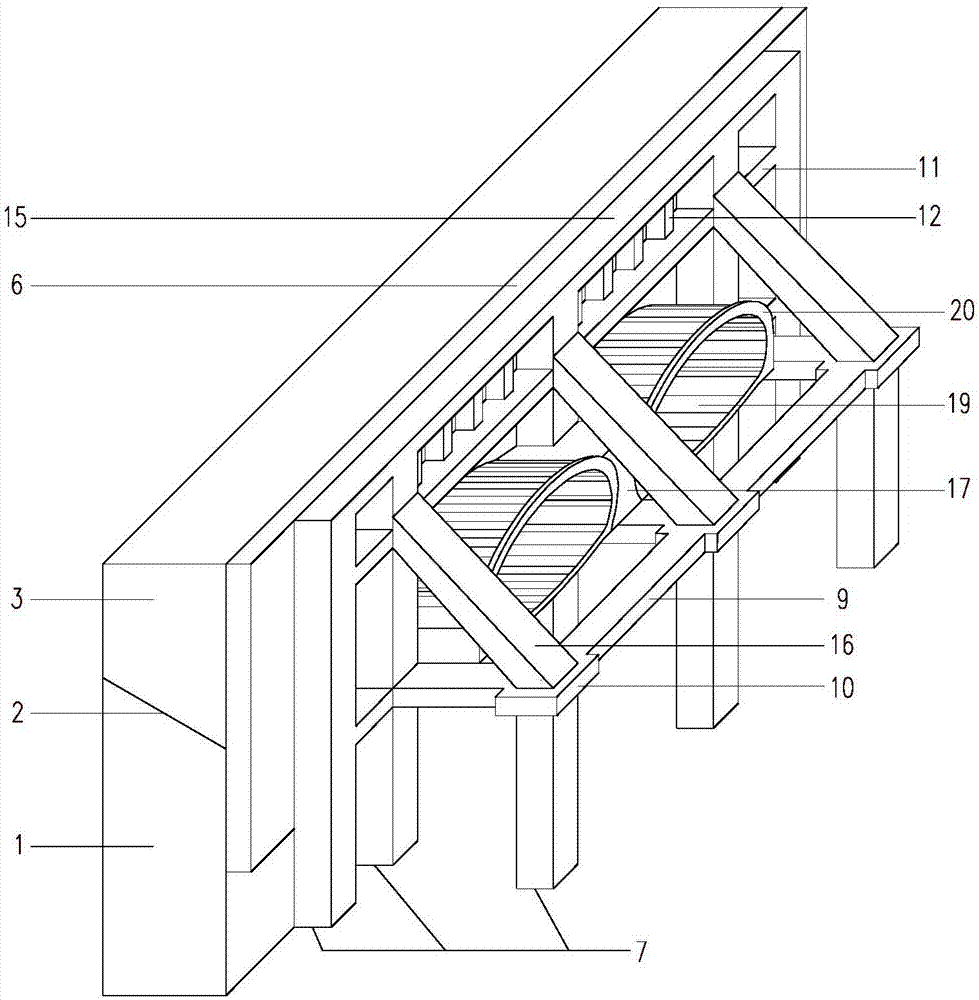

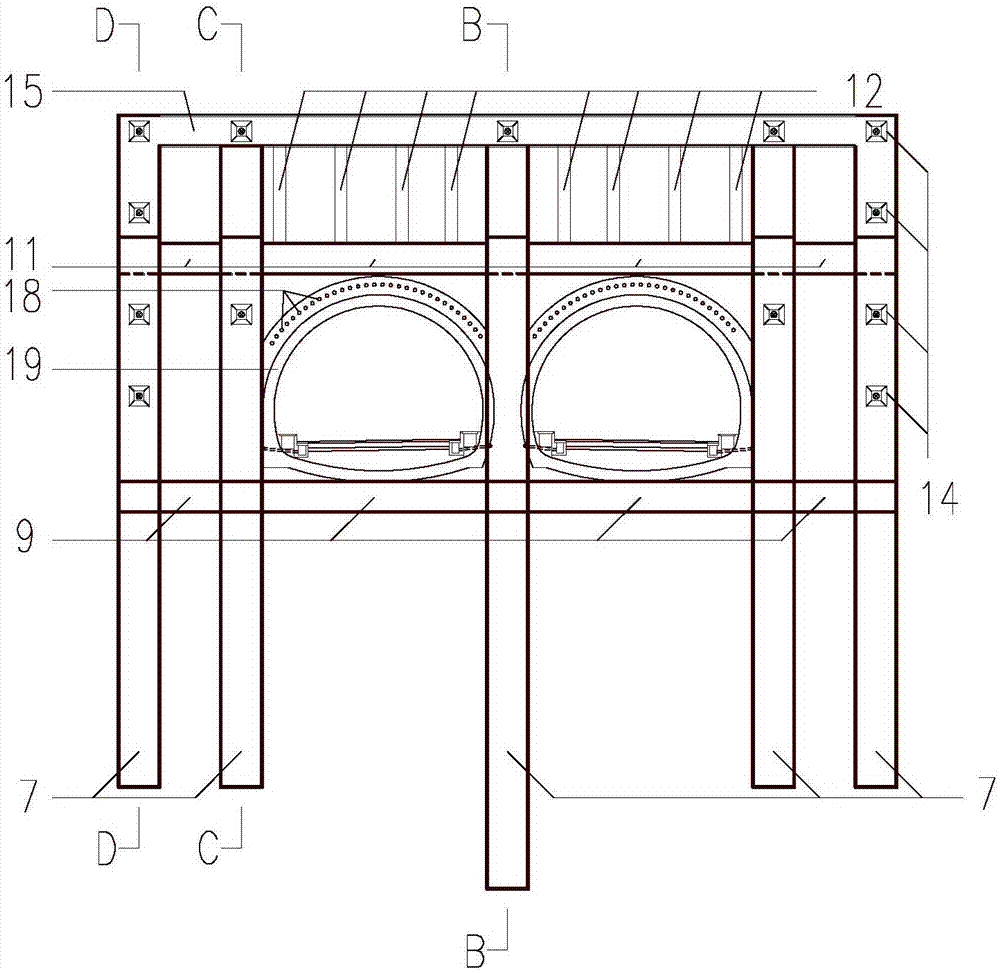

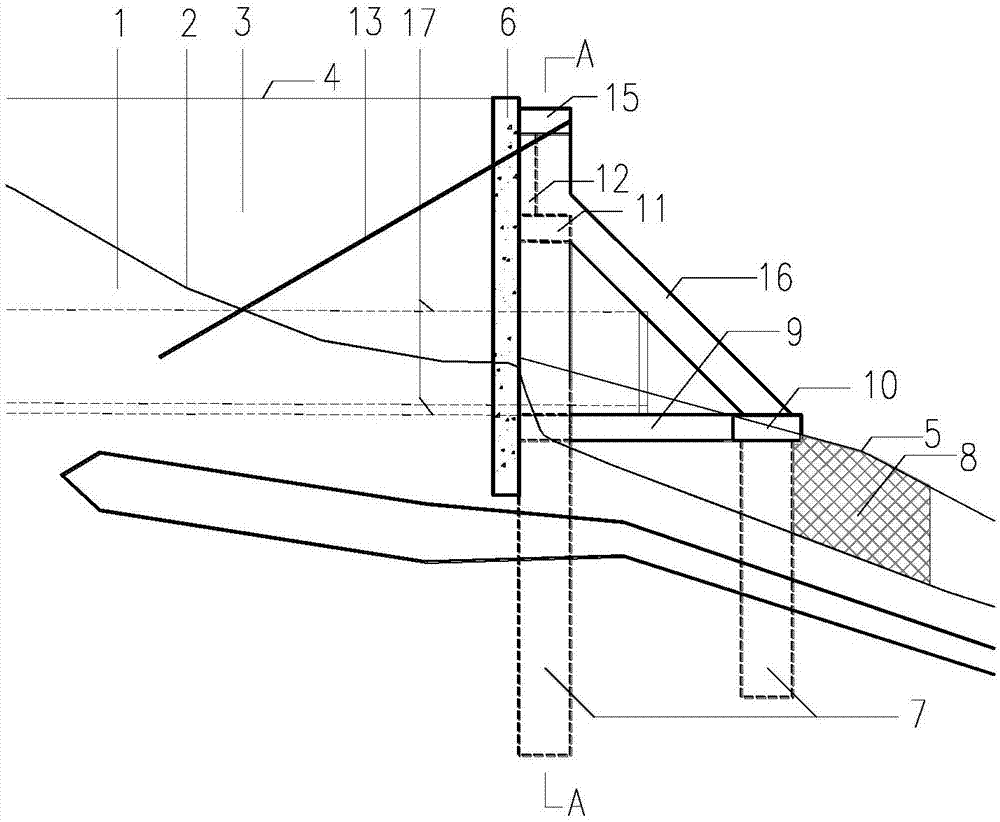

[0054] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0055] The reference signs in the drawings of the specification include:

[0056] Bedrock bearing body 1, potential slip surface 2, sliding body 3, slope top road surface 4, ground line 5, supporting structure 6, anti-slide pile 7, grouting reinforcement 8, ground connecting beam 9, pile end cap 10. Coupling beam 11, rib column 12, anchor cable 13, anchor pull head 14, crown beam 15, diagonal brace 16, multi-arch tunnel partition wall 17, advanced small conduit 18, tunnel lining structure 19, tunnel opening 20.

[0057] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The large-span tunnel shown is passing through the retaining structure of the existing retaining wall. This example is the exit section of a multi-arch tunnel. The tunnel goes under a municipal road with heavy traffic. The entrance mileage is ZK5+494.461 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com