Upper-and-down two-point type connecting joint of steel structure and polycarbonate (PC) outer wall

A technology for connecting nodes and steel structures, which is applied in the direction of building construction and construction, and can solve problems such as loose installation of wall panels and structures, inability to assemble panels accurately, and complex on-site construction, so as to avoid overall calculation and promote promotion and application , the effect of convenient calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

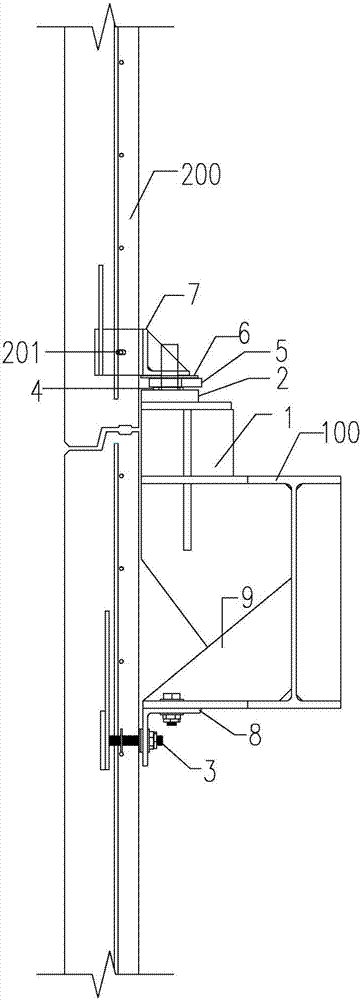

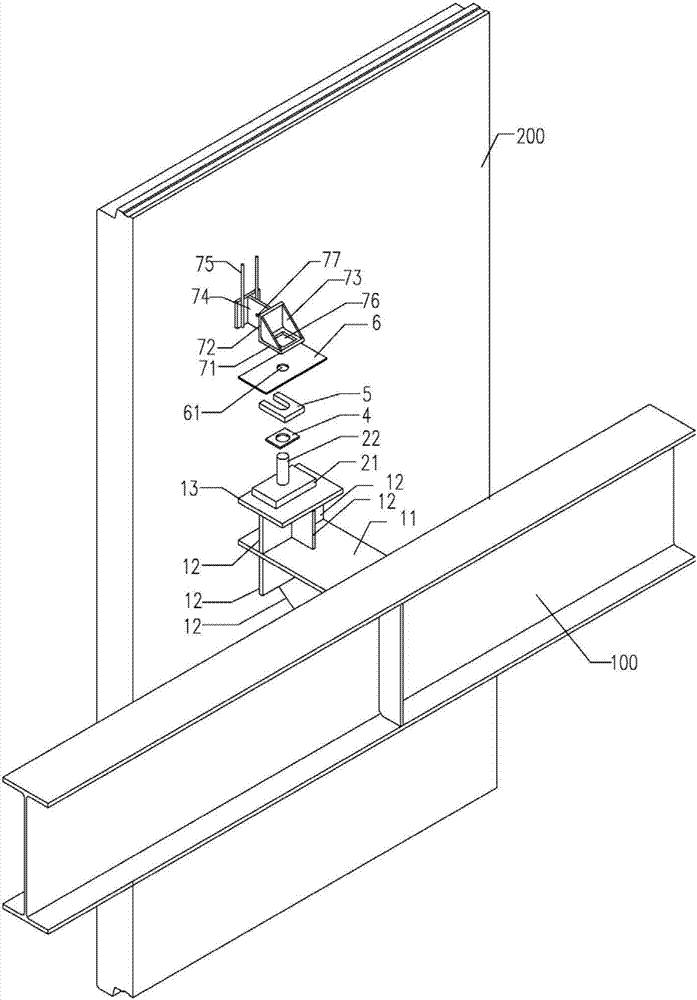

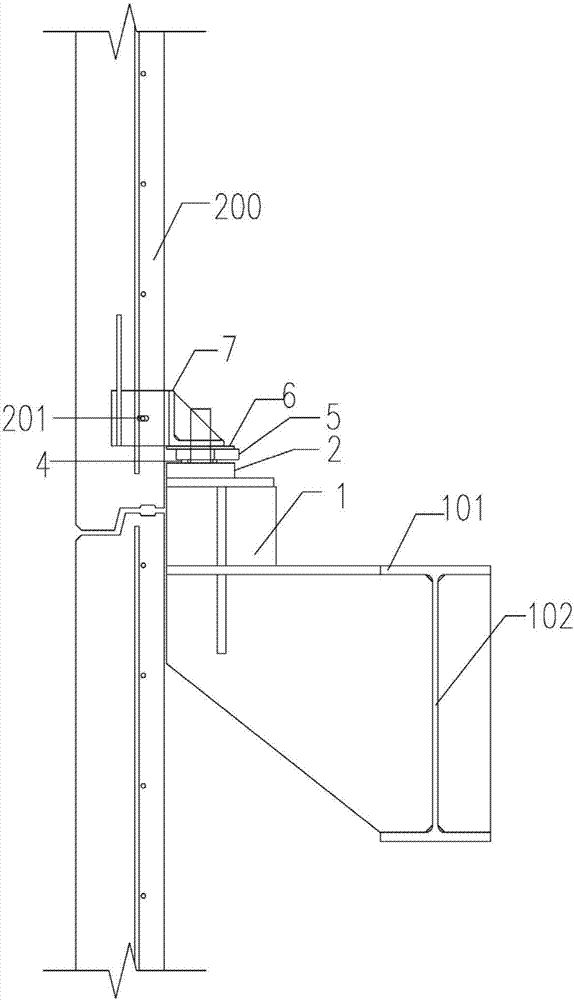

[0030] Please refer to the attached figure 1 To attach Figure 5 As shown, the present invention is a connection node between an upper and lower two-point steel structure and a PC exterior wall, which is composed of a PC exterior wall 200, a steel structure side beam 100, a first bracket 1, a connection base 2, embedded bolts 3, a resistance The welding plate 4, the spacer 5, the positioning plate 6, the embedded part 7, the connecting angle steel 8 and the second bracket 9 are composed of several parts.

[0031] Wherein, the PC exterior wall 200 is spliced up and down, and is divided into an upper PC exterior wall and a lower PC exterior wall. The PC exterior wall 200 is a single-layer wallboard, double-layer wallboard, single-layer insulation board or double-layer composite insulation board with core.

[0032] The steel structure edge beam 100 is arranged on one side of the PC exterior wall 200 below, and it can be an H-shaped steel beam.

[0033] The bracket 1 is welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com