Purlin support structure of a curved roof

A purlin bracket and curved surface technology, which is applied to roofs, building components, building structures, etc., can solve the problems of difficult purlin bracket installation, errors, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

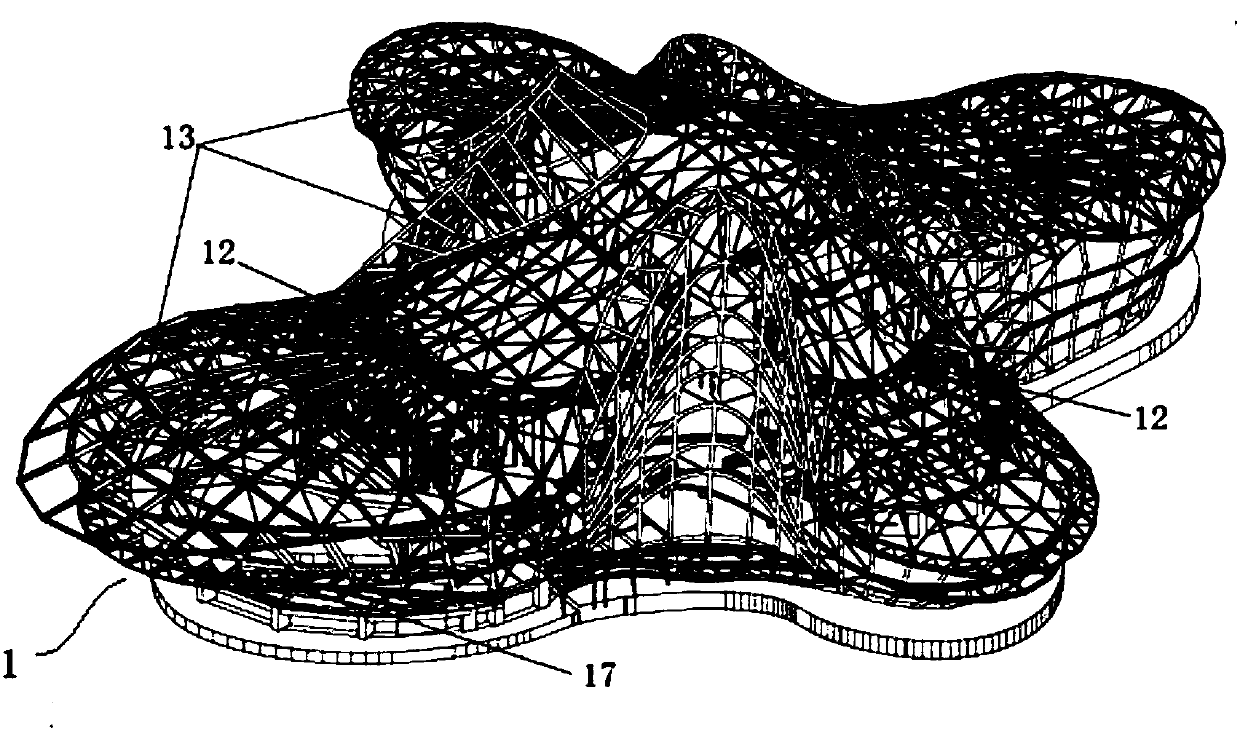

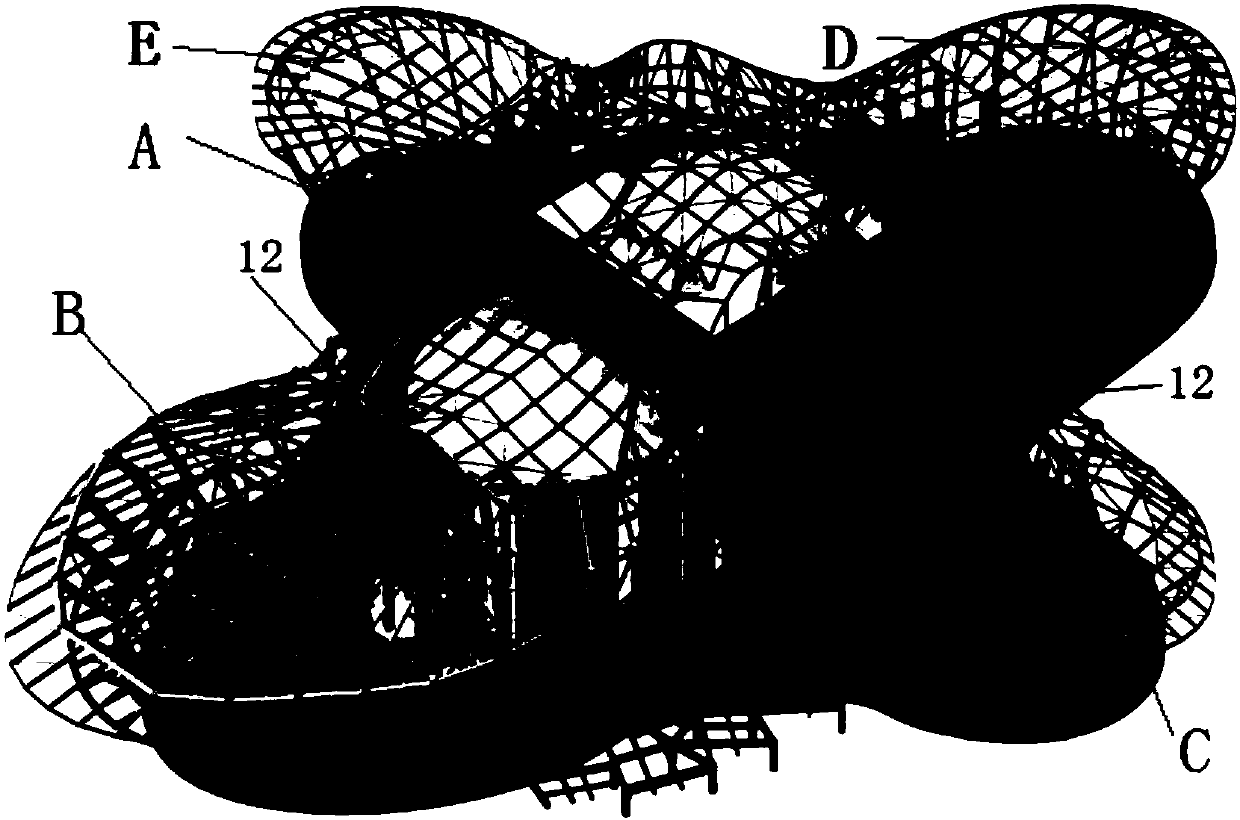

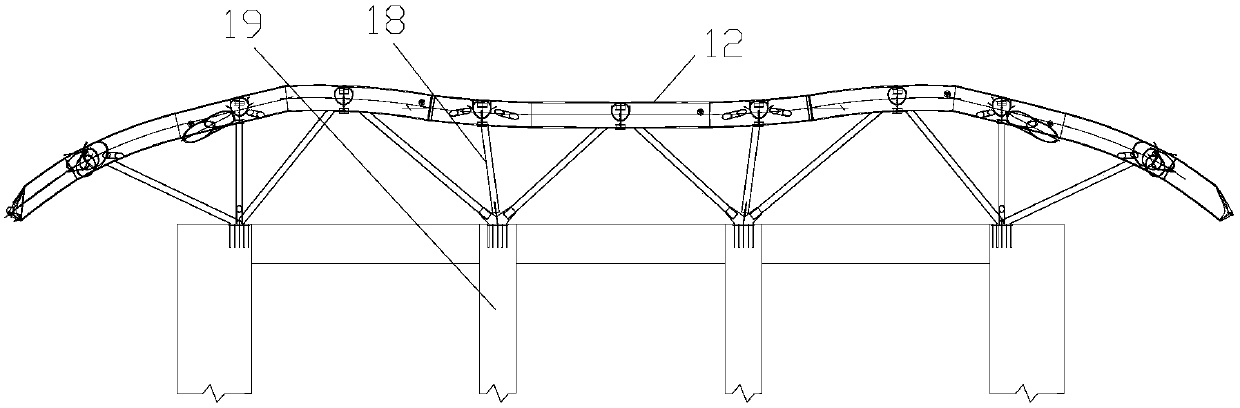

[0037] like figure 1 and figure 2 As shown, the steel structure 1 of a large theater is very urgent when constructing the theater. In order to reduce the impact of removing the membrane on the construction period, it is necessary to carry out partition construction. However, since the whole theater is designed as a whole, it is divided into complete If construction is carried out in an independent area, the deformation of the steel structure 1 during the dismantling process will cause the areas to fail to close together. In order to solve the above problems, the designers creatively divided the theater into area A in the middle, and four side areas B, C, D, and E around it. A shared boundary 12 is set at the boundary of adjacent areas, and the shared boundary 12 fixes the purlins 13 of each area. In order to make the structure of the common boundary 12 have a certain degree of elasticity, so as to be able to adapt to the overall deformation of the steel structure after the ...

Embodiment 2

[0045] On the basis of the above-mentioned patent, a curved roof is built above the steel structure. like Figure 8 and Figure 9 As shown, in order to solve the functions of waterproofing, heat preservation, and sound insulation of the building, the structure of the curved roof is as follows: it includes a profiled plate 201, and the lower part of the profiled plate 201 is connected and fixed with the steel structure through a galvanized folding part 208; There is a waterproof and gas-insulating membrane 202, and above the waterproof and gas-insulating membrane 202 is the first thermal insulation layer formed by the first centrifugal glass wool 217; above the first centrifugal glass wool 217, there is a single-sided aluminum foil thermal insulation rock wool 203; single-sided aluminum foil thermal insulation rock wool The main purlin 204 is fixed above the 203, and the main purlin 204 is fixed with a connecting plate 205. The connecting plate 205 is provided with two upper a...

Embodiment 3

[0051] Outside the building, curtain wall panels are generally installed as a decorative layer. The decorative layer needs to be lapped on the fixed support rods, and then the decorative layer is fixed. In order to ensure the stability of the fixation, the support points of the decorative layer need to be set on the steel structure. That is to weld and fix the purlin support structure 3 on the steel structure,

[0052] like Figure 10 As shown, the purlin support structure 3 includes a copper sleeve 301 welded on the steel structure 1, the copper sleeve 301 is provided with an internal thread, the copper sleeve 301 is threaded with a purlin support 302, and both ends of the fixed pole 303 are connected to the The purlin support 302 is connected and fixed. Then the fixing rod 303 fixes the decoration layer. However, the purlin support structure 3 will pass through the roof, thereby breaking through the waterproof layer of the roof, resulting in failure of the waterproof laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com