A Prism Pose Adjustment Mechanism

A pose adjustment and prism technology, applied in installation, optics, instruments, etc., can solve the problem that the final product is difficult to fully satisfy, and achieve the effect of reliable locking, precise adjustment and high rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

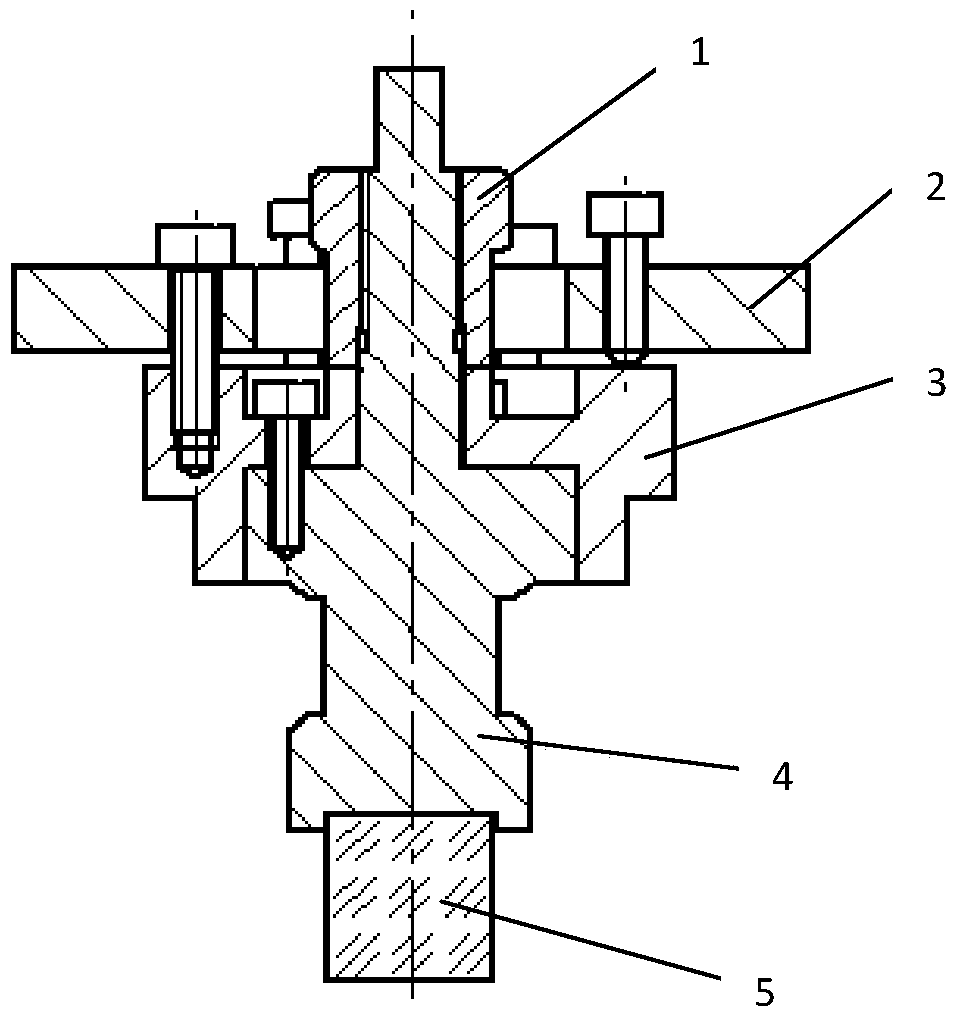

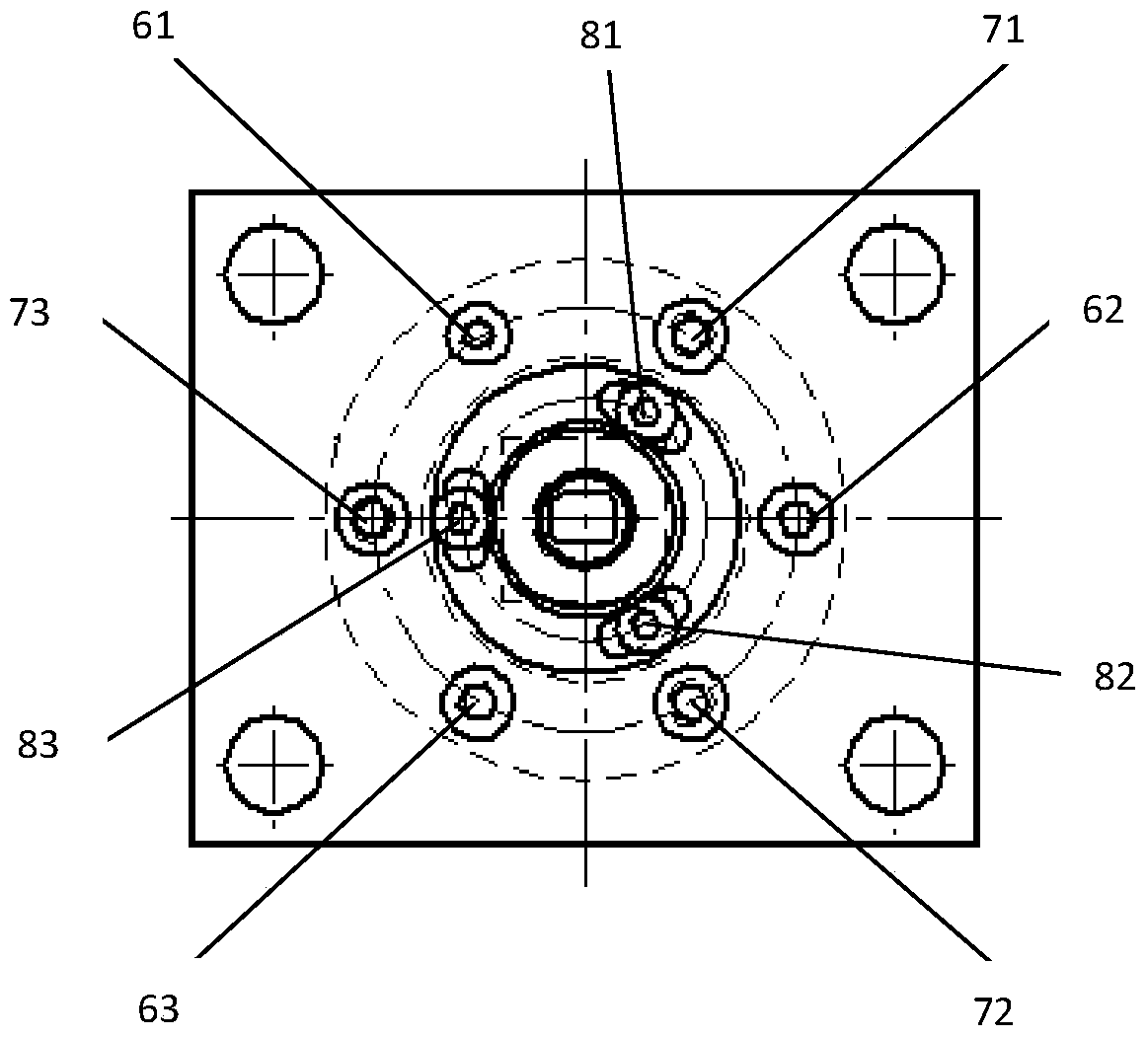

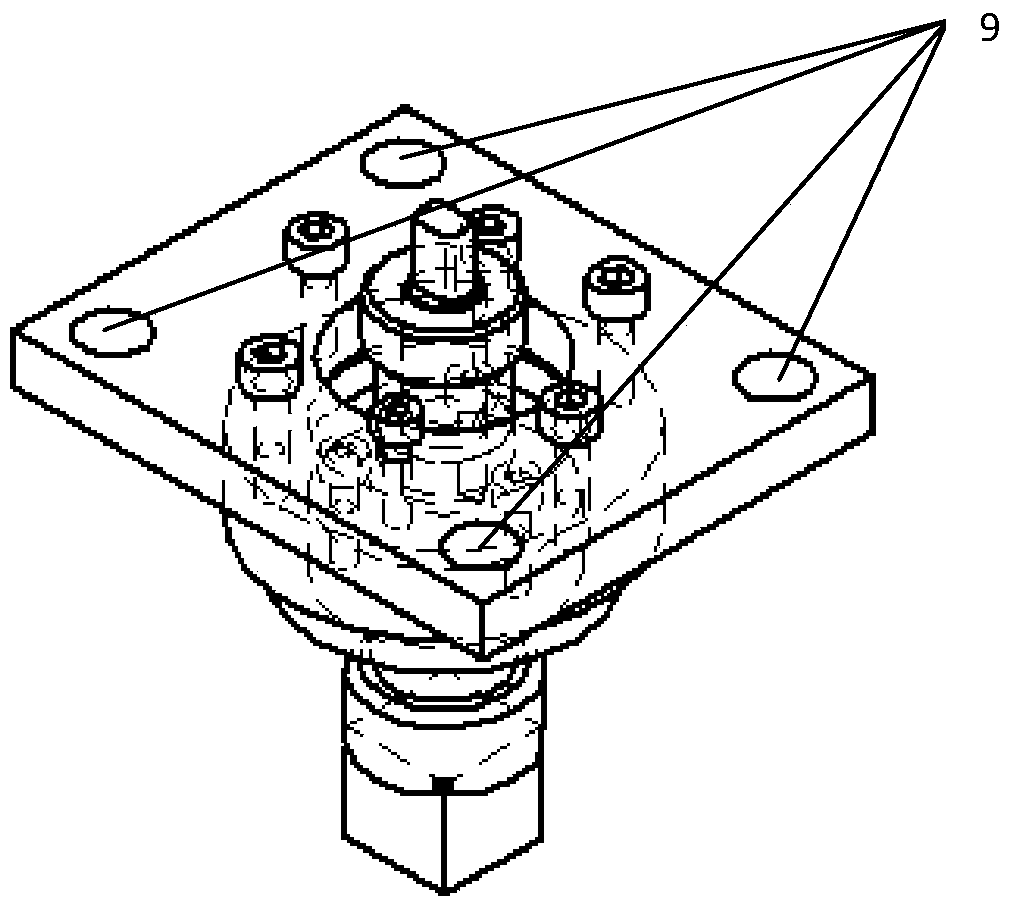

[0028] See figure 1 ‐5, a prism posture adjustment mechanism, including a stationary seat 2, a locking screw sleeve 1, a movable seat 3, a prism shaft 4, and a cubic prism 5; the prism shaft 4 penetrates the locking screw sleeve 1 and the movable seat 3; the locking screw A movable seat 3 is arranged in the vertical direction between the sleeve 1 and the prism shaft 4; the lower end of the prism shaft 4 is bonded with a cubic prism 5 through a structural adhesive; the prism shaft 4 and the movable seat are axially pre-tightened by a pre-tightening screw set; The locking screw sleeve 1 is arranged in an opening in the middle of the stationary seat 2 and there is a gap between the stationary seat 2; the contact surface of the prism shaft 4 and the movable seat 3 is evenly provided with at least two screw holes for installing the pre-tightening screw set; The contact surface of the movable base 3 and the prism shaft 4 is provided with an annular sink groove; the bottom of the sink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com