Non-pillar mining roadway sidewall closing device and construction method thereof

A technology without coal pillars and road gangs, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve the problems of poor material performance, poor sealing effect, time-consuming and labor-intensive, etc., to achieve strong overall plasticity, improve labor efficiency, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

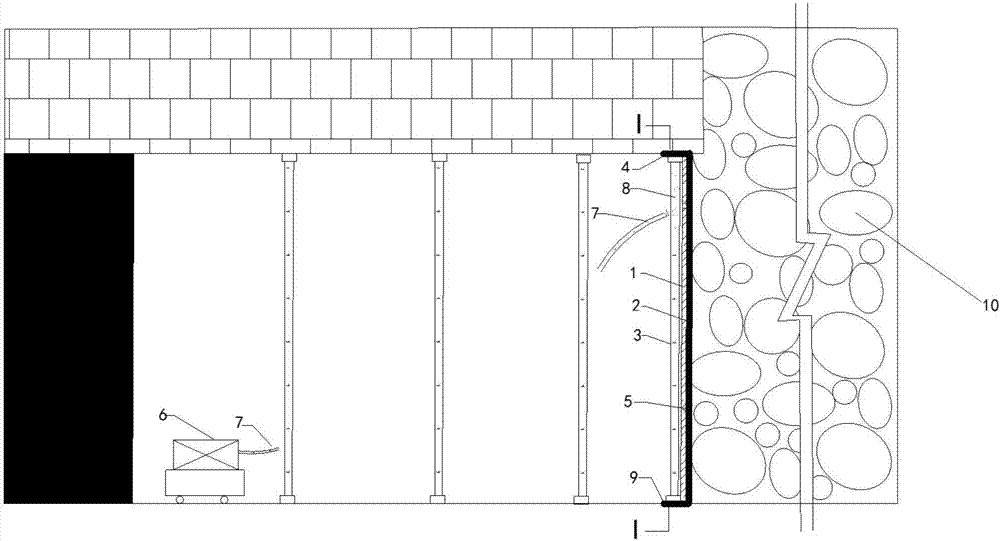

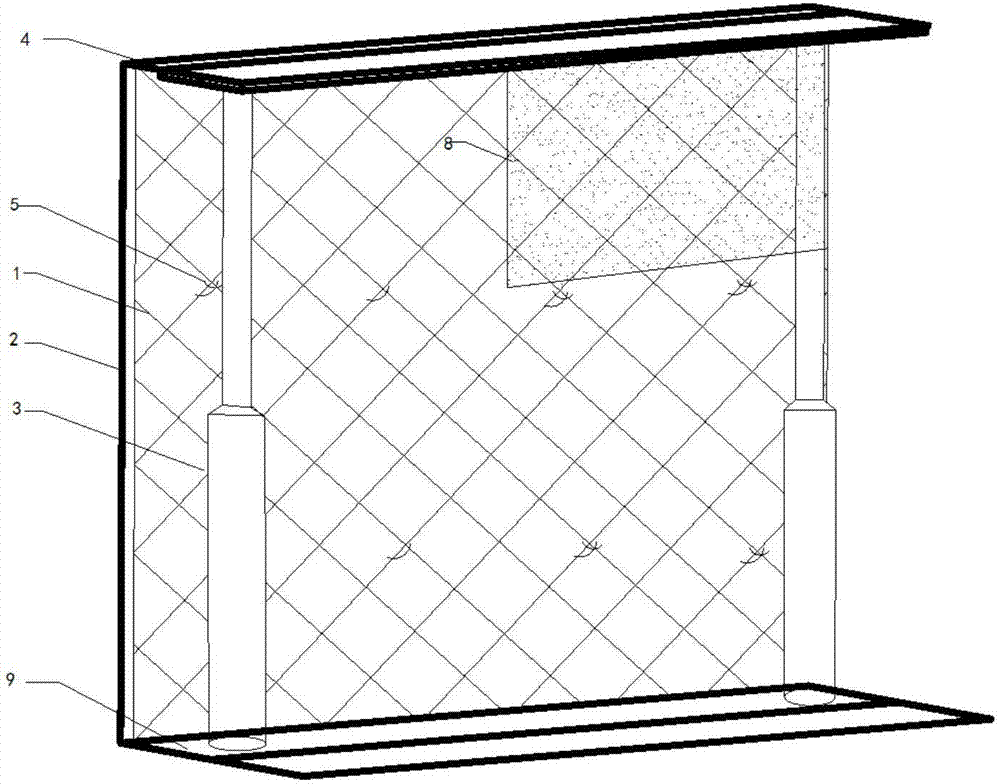

[0024] see figure 1 and figure 2 , the invention discloses a coal pillar-free mining roadside sealing device, which includes a plurality of gangue retaining pillars 3 arranged at intervals. The gangue-retaining pillar 3 is provided with a gangue-retaining net 1 on the side close to the goaf 10, and a flexible cloth 2 is attached and fixed on the gangue-retaining net 1 through a cable tie 5, and the upper end of the flexible cloth 2 passes through the gangue-retaining net 1. The column 3 and the upper steel beam 4 are fixed with the top plate along the groove, and the lower end of the flexible cloth 2 is fixed with the bottom plate along the groove through the gangue retaining column 3 and the lower steel belt 9 .

[0025] One side of the flexible cloth 2 faces the goaf 10 , and the surface of the gangue retaining net 1 is sprayed with a closed flexible material 8 by a spraying machine 6 and a slurry delivery pipe 7 .

[0026] The airtight flexible material 8 is an inorganic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com