Anode-cathode connector and connector device for battery or capacitor

A technology of connectors and positive and negative poles, which is applied in the field of electronic component testing, can solve the problems of inaccurate battery or capacitor results, damage to the positive and negative poles of batteries or capacitors, and achieve the effects of ensuring product quality, preventing damage, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

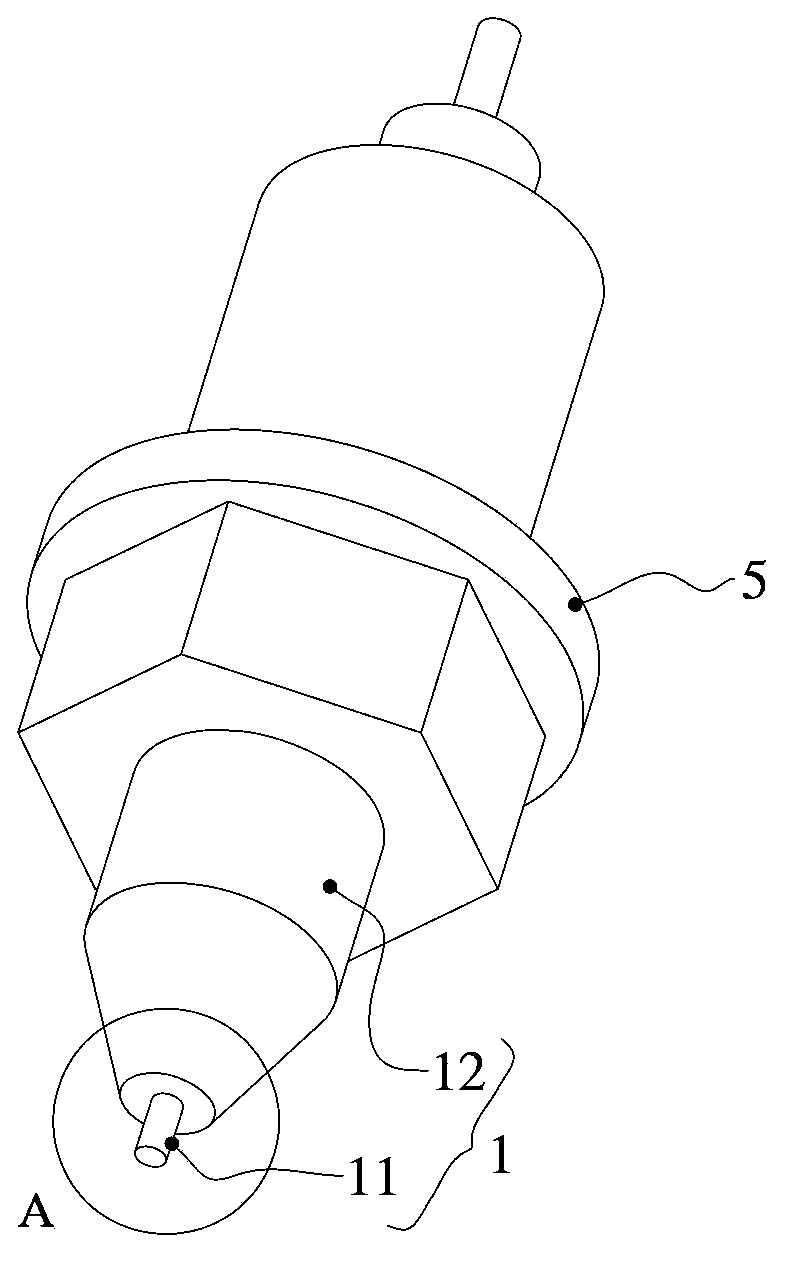

[0041] Such as Figure 1-8 Shown is a preferred embodiment provided by the present invention.

[0042] The present invention is achieved in this way, a connecting piece 1 for the positive and negative poles of a battery or capacitor, the connecting piece 1 has a metal part for conduction detection of the positive and negative poles of the battery or capacitor, and the metal part is provided with a connecting piece for detecting Heat sensor 2 for heating temperature. The thermal sensor 2 has high sensitivity. By setting the thermal sensor 2 on the connector 1, when testing the battery or capacitor 100, the temperature on the connector 1 of the positive and negative poles of the battery or capacitor can be monitored in real time. Calorific value, when the calorific value of the positive and negative connectors 1 of the battery or capacitor exceeds the safe value, the test equipment will cut off the voltage loop and current loop of the test battery or capacitor, and the device w...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the thermal sensor 2 and the connecting piece 1 are arranged separately. Such as Figure 12 As shown, one end of the connector 1 is connected with a connection wire 13 for connecting to an external testing device, and the thermal sensor 2 is sandwiched on the connector 1 by a fastener 14 . In this way, when testing a battery or a capacitor, the heat generated by the connection of the thermal sensor 2 can be detected, thereby avoiding damage to the battery or capacitor due to overheating.

Embodiment 3

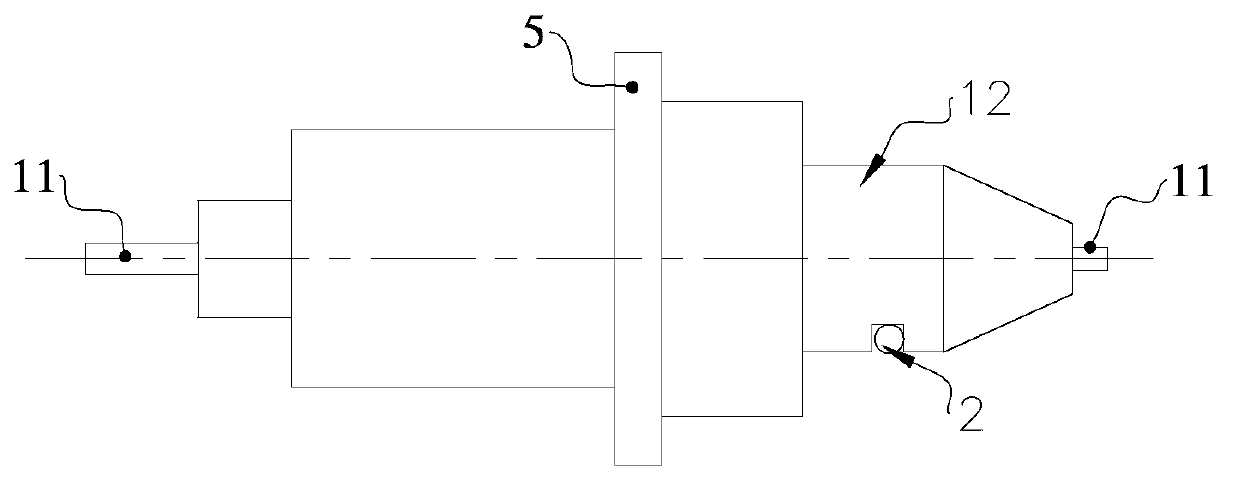

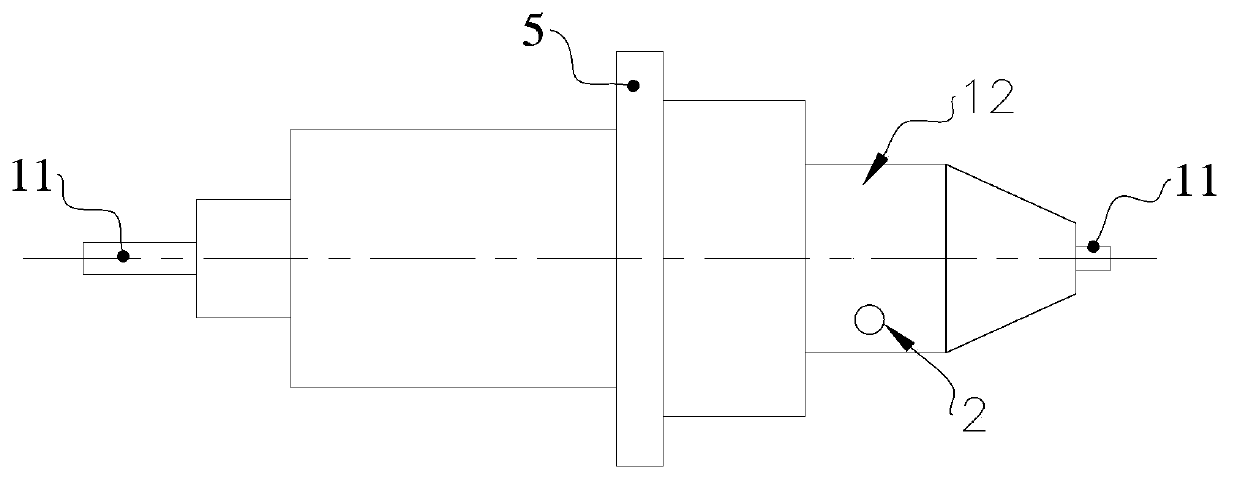

[0060] Such as Figure 13 with Figure 14 As shown, the connector 1 in this embodiment includes a first connector 11 and a second connector 12 hinged to each other, and a first elastic member is sandwiched between the first connector 11 and the second connector 12 3. In this embodiment, the first elastic member 3 is a torsion spring. The thermal sensor 2 is pasted or embedded or fused on the metal part of the second connecting member 12 .

[0061] In this way, the positive and negative poles of the battery or capacitor 100 are clamped by the first connecting piece 11 and the second connecting piece 12, and while the electrical signal in the battery or capacitor 100 is turned on, the electrical signal on the connecting piece 1 is detected. The heat keeps the battery or capacitor 100 in a good testing environment all the time, ensuring the stability and accuracy of testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com