Patents

Literature

40results about How to "Real-time monitoring of heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

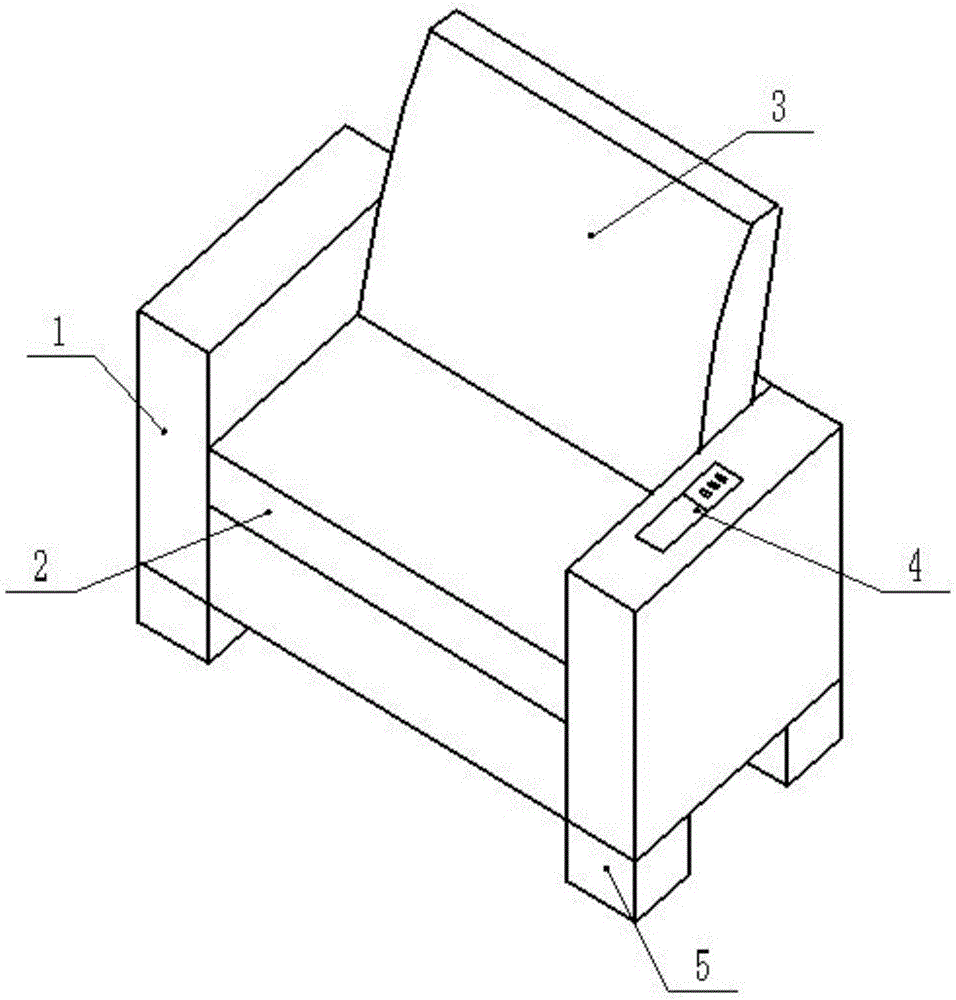

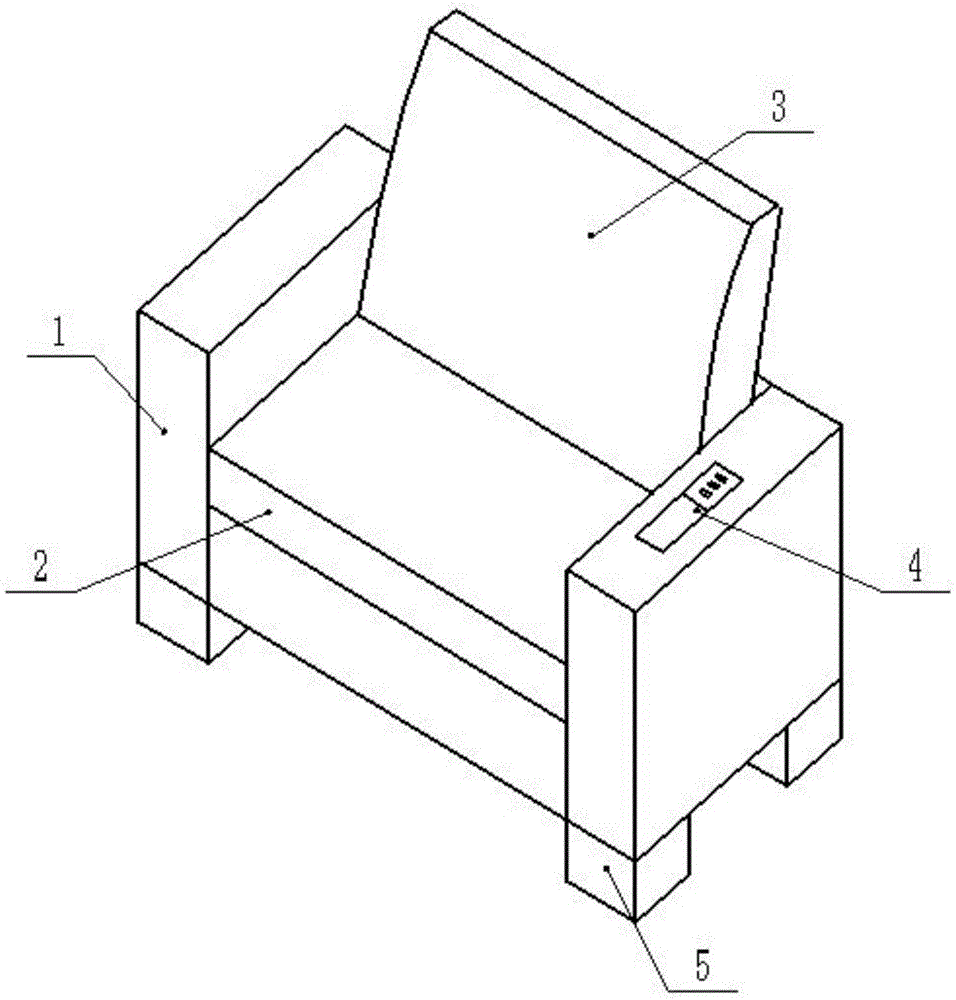

Portable type household sofa

InactiveCN106617887ARealize the charging functionRealize the heating functionSofasCouchesEmbedded system

The invention discloses a portable type household sofa. The portable type household sofa comprises a sofa seat, wherein a seat cushion and a backrest are arranged on the sofa seat; the sofa seat comprises a processor and a control panel; the control panel is provided with a display screen, jacks and a plurality of keys; a heater band and a temperature sensor are arranged in the seat cushion and the backrest; the processor is connected with the heater band, the temperature sensor, the display screen and the keys respectively; bases are fixedly mounted at four corners of the bottom of the sofa seat. The portable type household sofa has high functionality, is convenient to use and meets daily increasing requirements of people.

Owner:湖南海裕信息科技有限公司

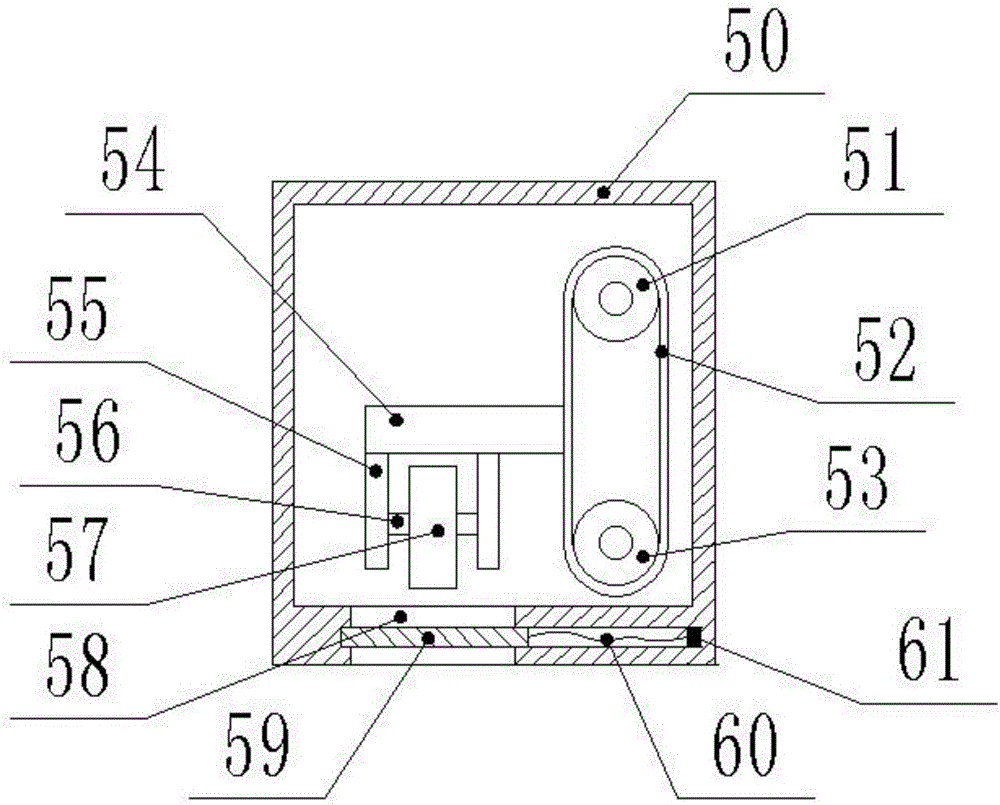

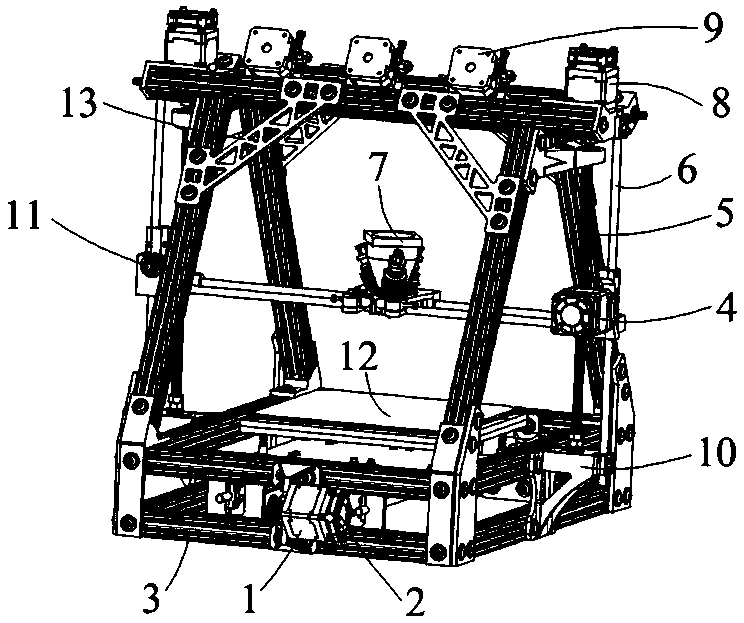

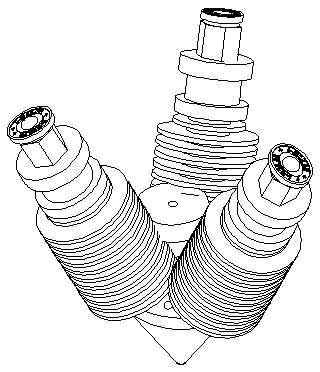

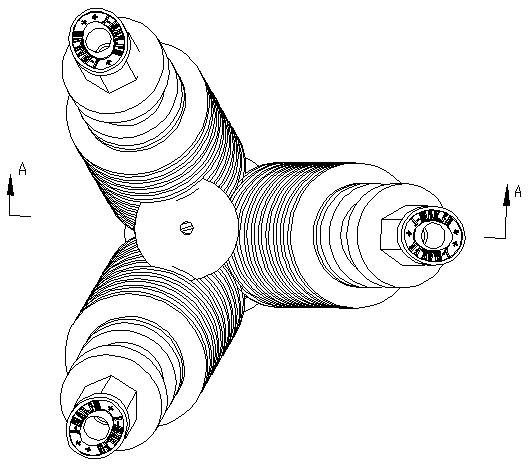

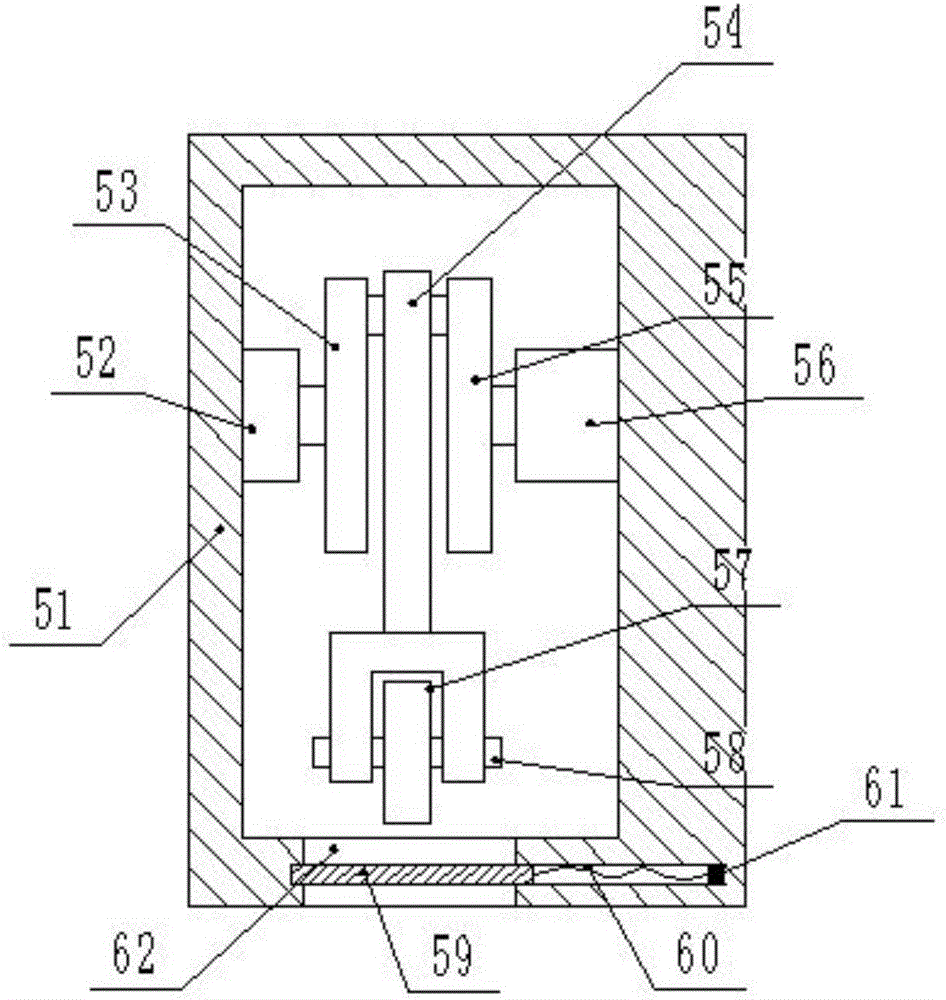

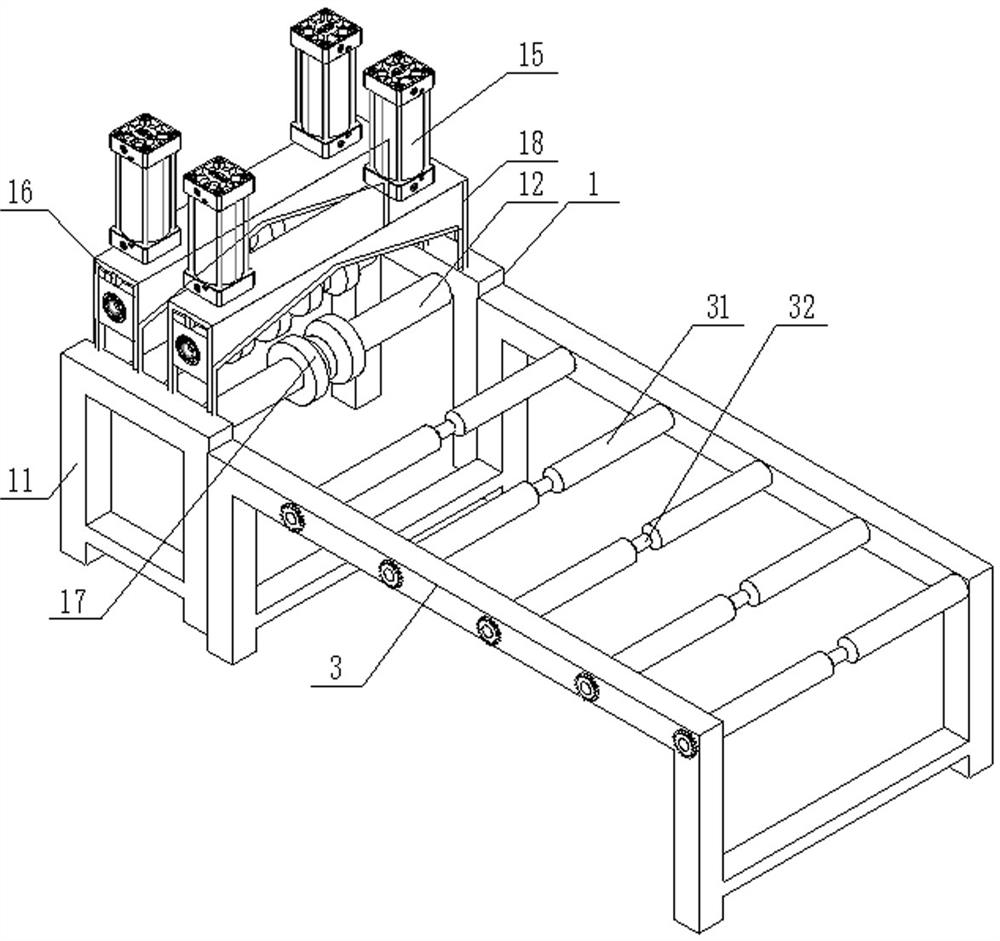

Color 3D printer

InactiveCN105500713ASmooth change in resistancePrevent mutations in resistanceAdditive manufacturing apparatusCeramic shaping apparatusSprayerColor printing

The invention relates to a color 3D printer aiming to solve the technical problems that in the prior art, the requirement of a 3D printer for part cooperation is high, the 3D printer is damaged easily, and is inconvenient to maintain, when multi-color printing is carried out, colors of materials are mixed unevenly, and color 3D printing can not be completed. The color 3D printer comprises a sprayer and a printer body. The sprayer comprises a heating and mixing assembly and at least two feeding assemblies. The printer body comprises a rack, a tray installed on the rack, an X-axis moving mechanism and a Y-axis moving mechanism, wherein the X-axis moving mechanism and the Y-axis moving mechanism control the tray to move. The rack is further provided with a Z-axis moving mechanism for controlling the sprayer to move. The X-axis moving mechanism, the Y-axis moving mechanism and the Z-axis moving mechanism form a Cartesian coordinate system. The color 3D printer has the advantages that color 3D printing can be achieved without replacing the sprayer; all the parts are convenient to assemble and disassemble; three stepping motors are used for controlling silk conveying in three directions, locating is stable, and maintaining and replacing of the later period are convenient, and the whole process is high in automation degree.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

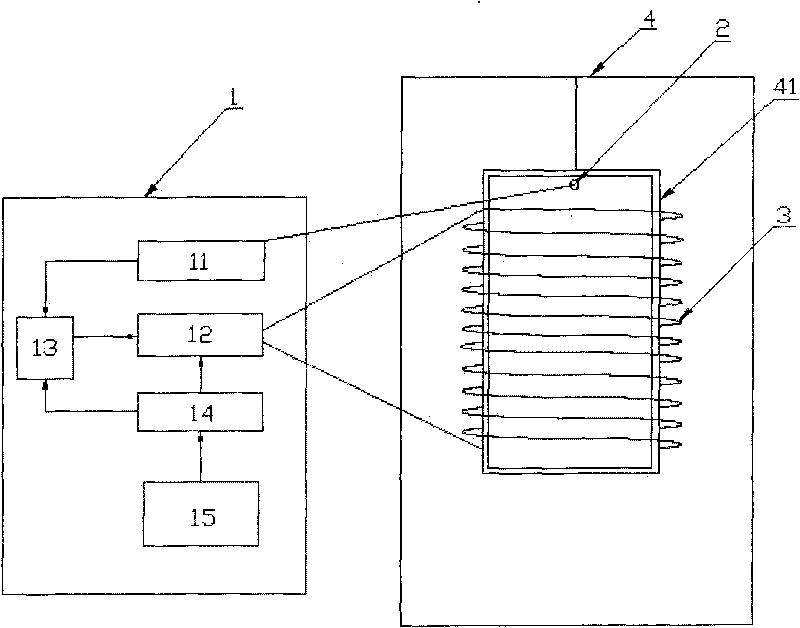

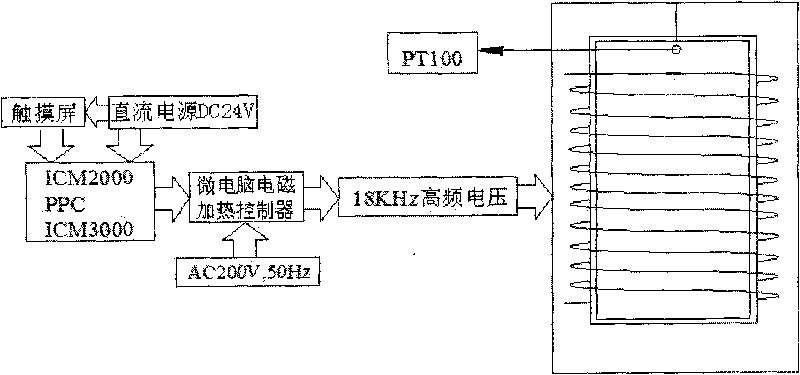

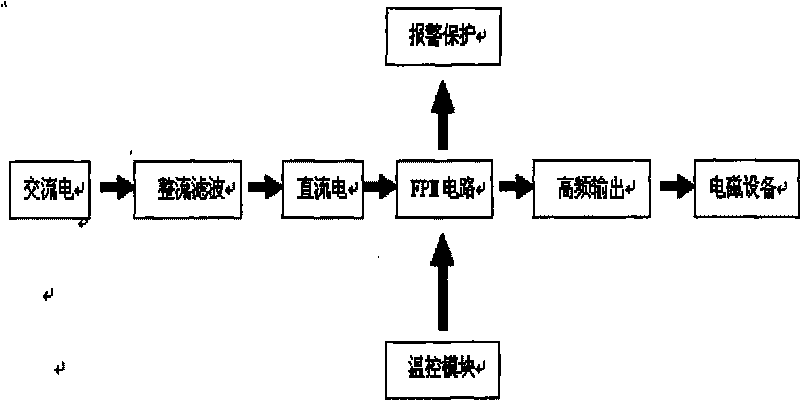

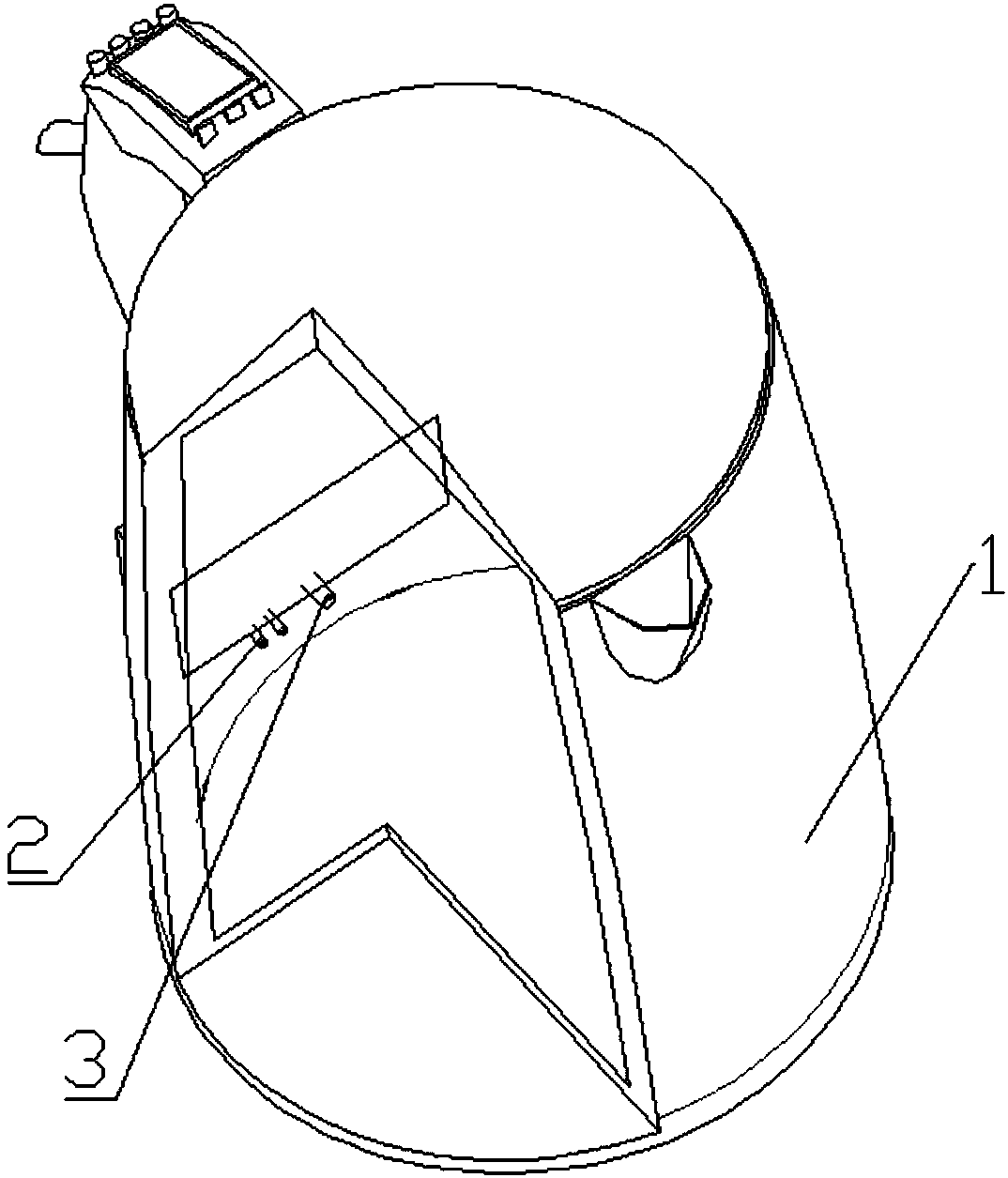

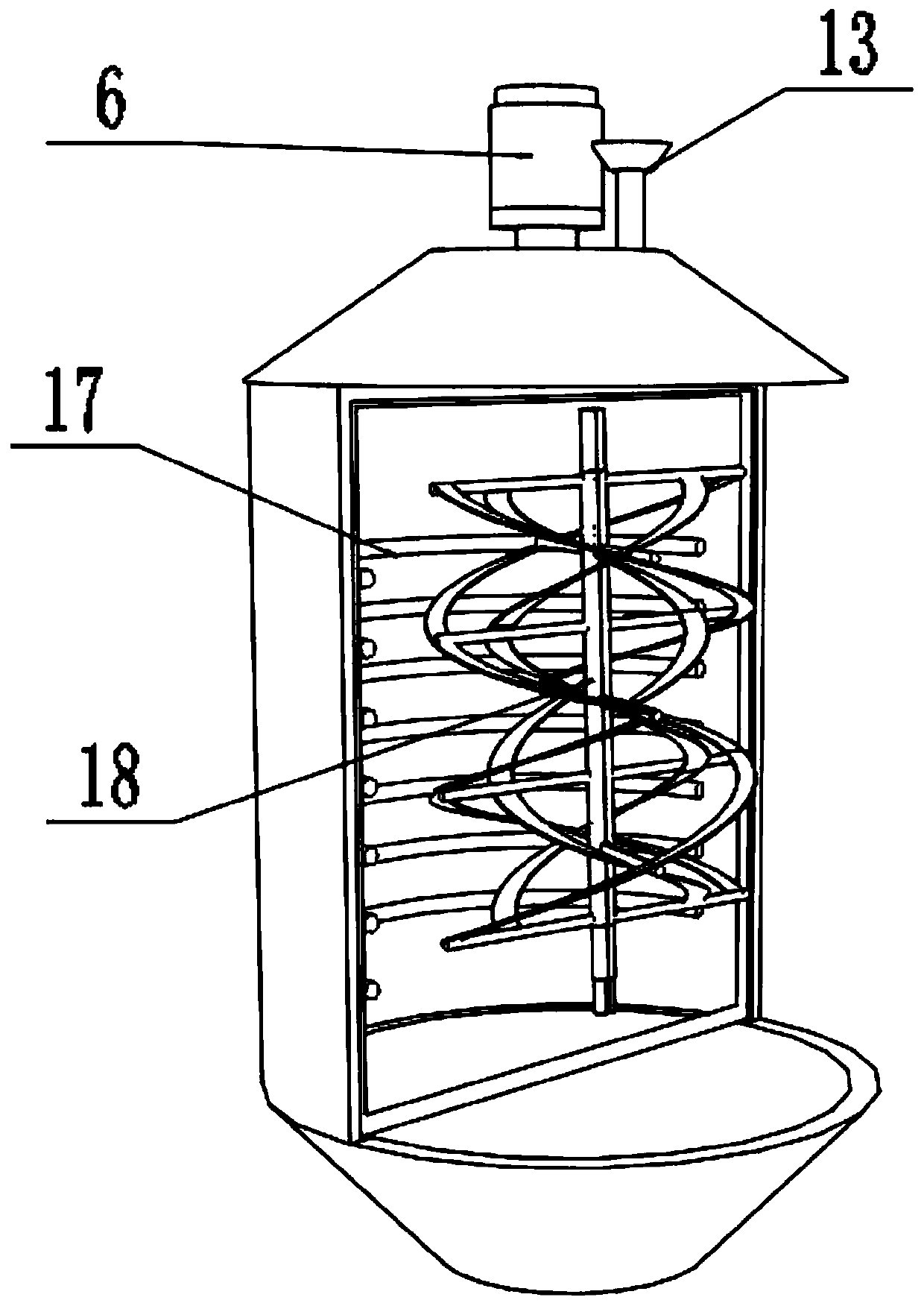

Electromagnetic heating temperature control smelting furnace

InactiveCN101718492AIncrease profitReduce consumptionCrucible furnacesTemperature controlEngineering

The invention discloses an electromagnetic heating temperature control smelting furnace which comprises a smelting furnace body and an electromagnetic heating temperature control system, wherein the smelting furnace body comprises a heating room; the electromagnetic heating temperature control system comprises an electromagnetic heating temperature control device, an electromagnetic coil and a temperature measurement sensor; the electromagnetic coil is surrounded outside the heating room; after alternating current (AC) high-frequency current is input by the electromagnetic heating temperature control device, an alternating magnetic field is generated so as to ensure that the heating room generates vortex flows to heat; the temperature measurement sensor is arranged in the heating room, connected with the electromagnetic heating temperature control device and used for detecting temperature in the heating room and acquiring data; and the electromagnetic heating temperature control device regulates the amount and the on-off of the AC high-frequency current according to the acquired data as required. The electromagnetic heating temperature control smelting furnace can save energy, protect the environment, exactly measure and control the temperature, save labor power and improve the safety.

Owner:青岛福润德自动化技术有限公司

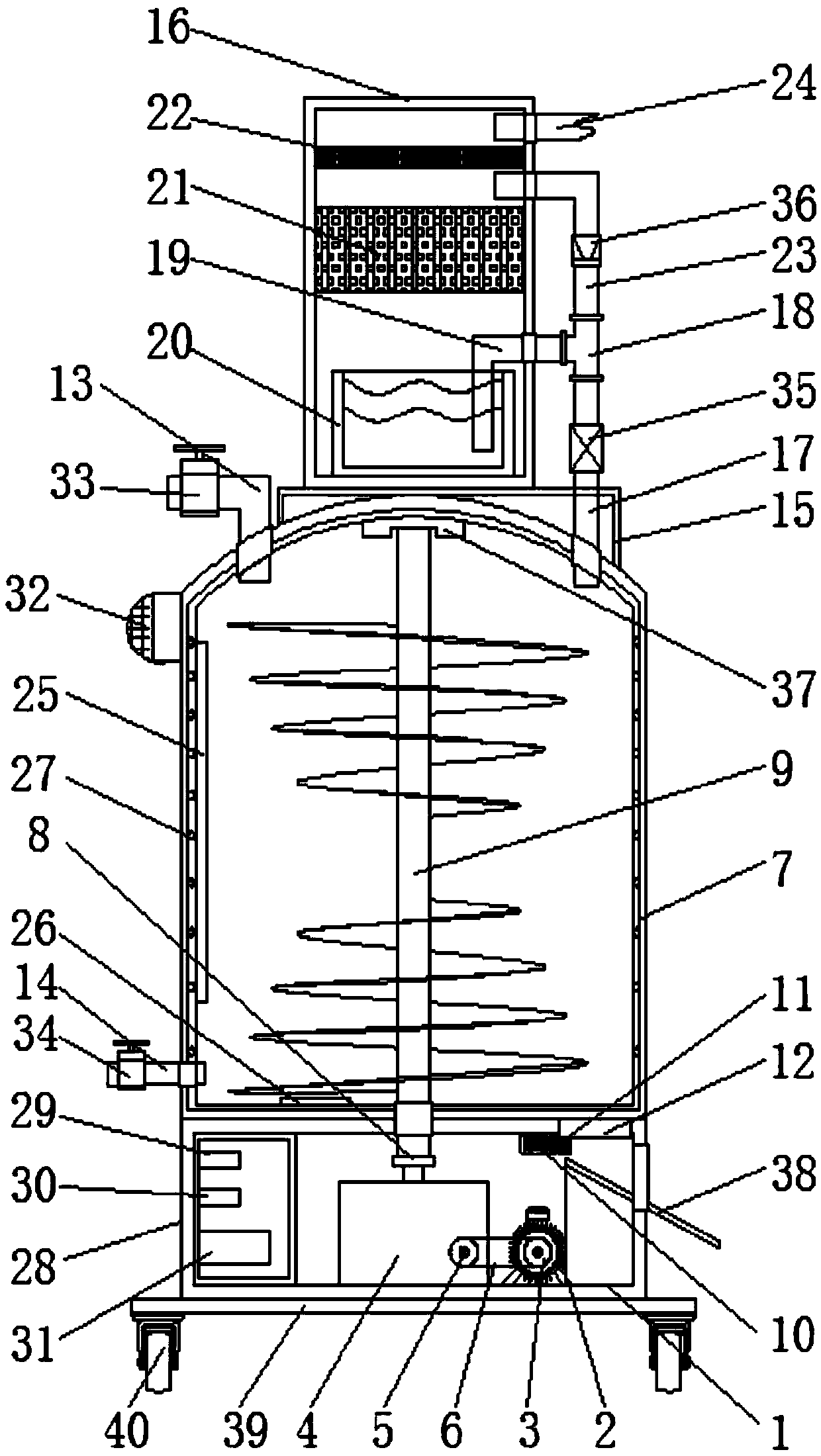

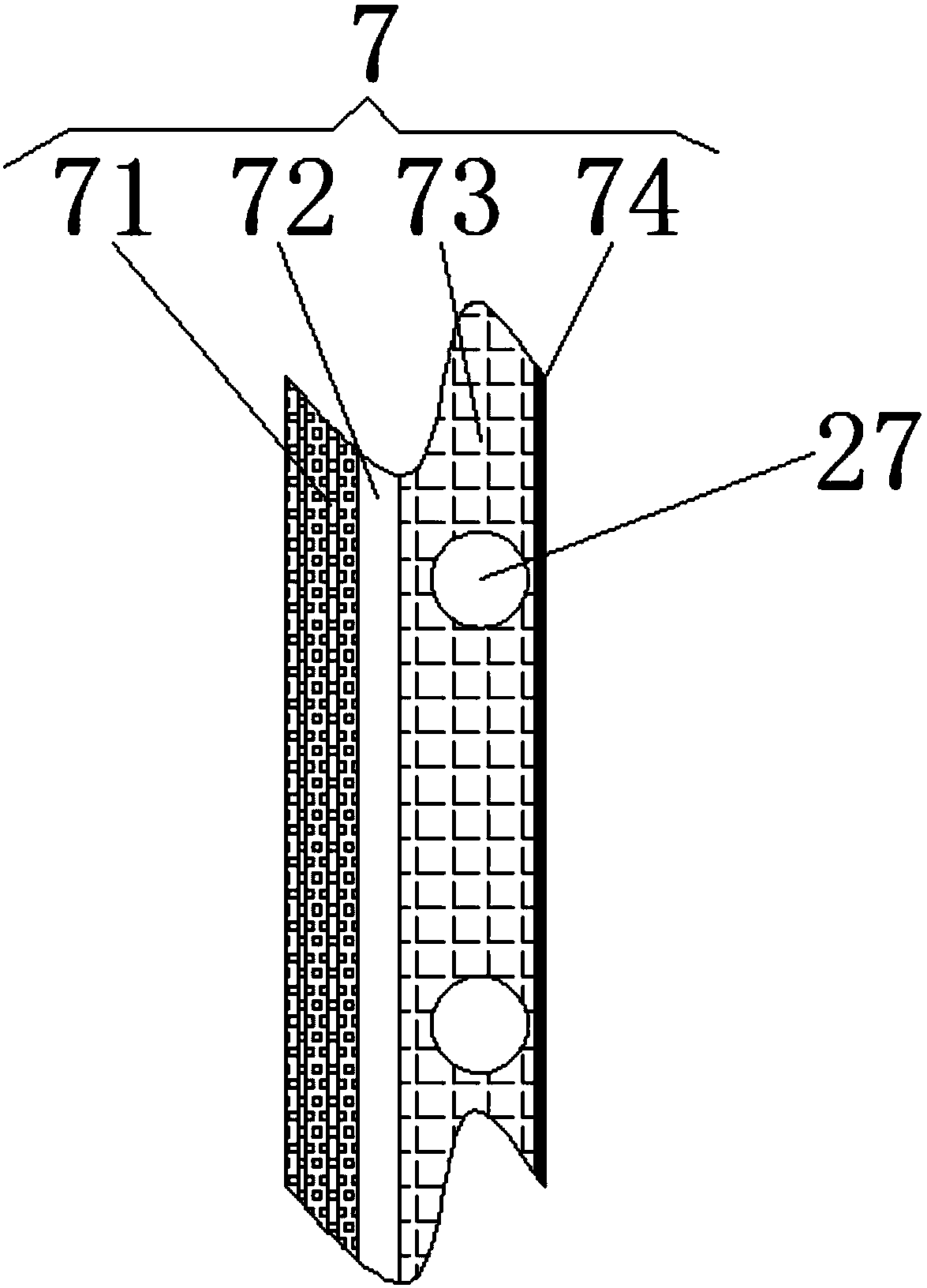

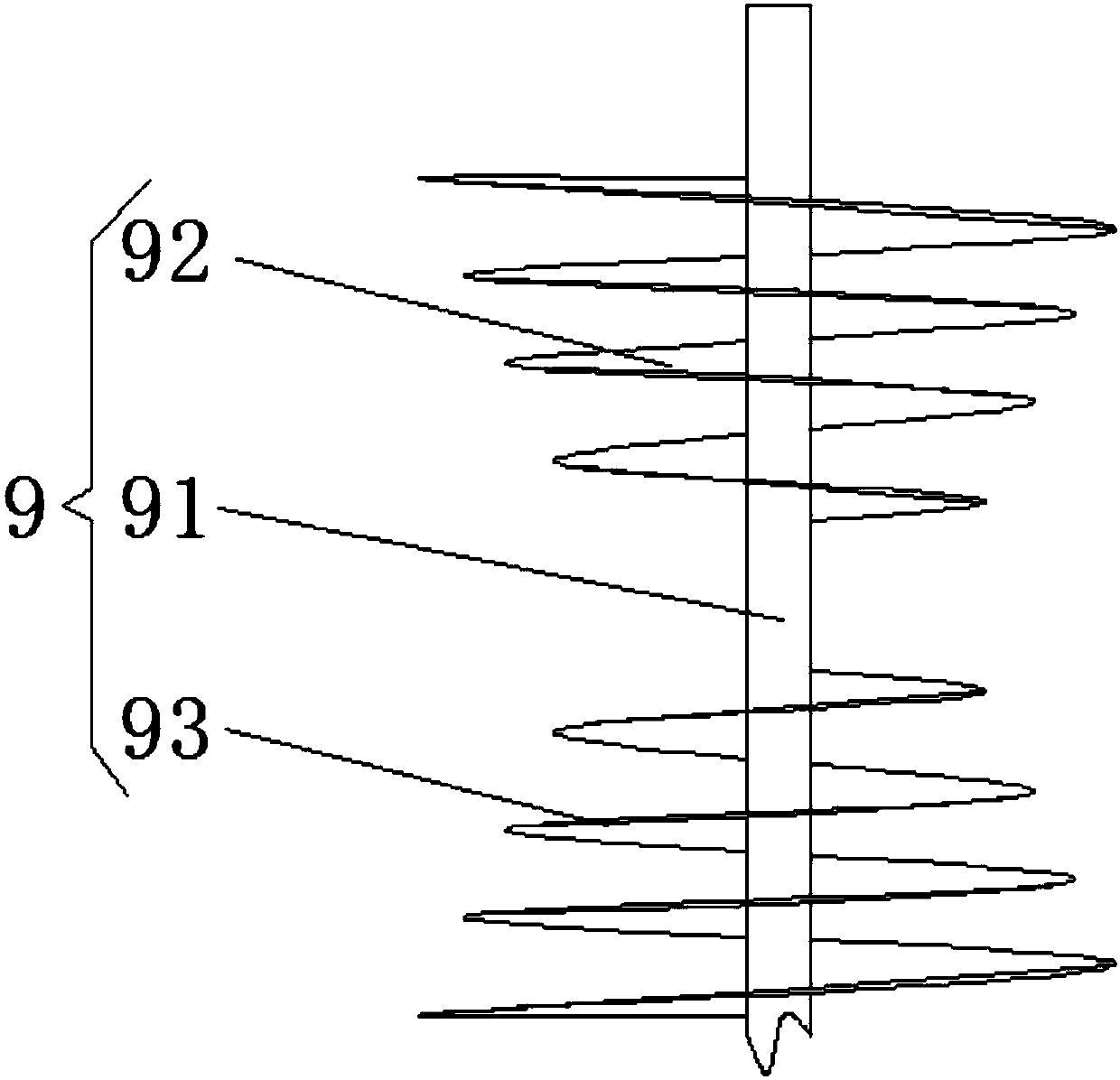

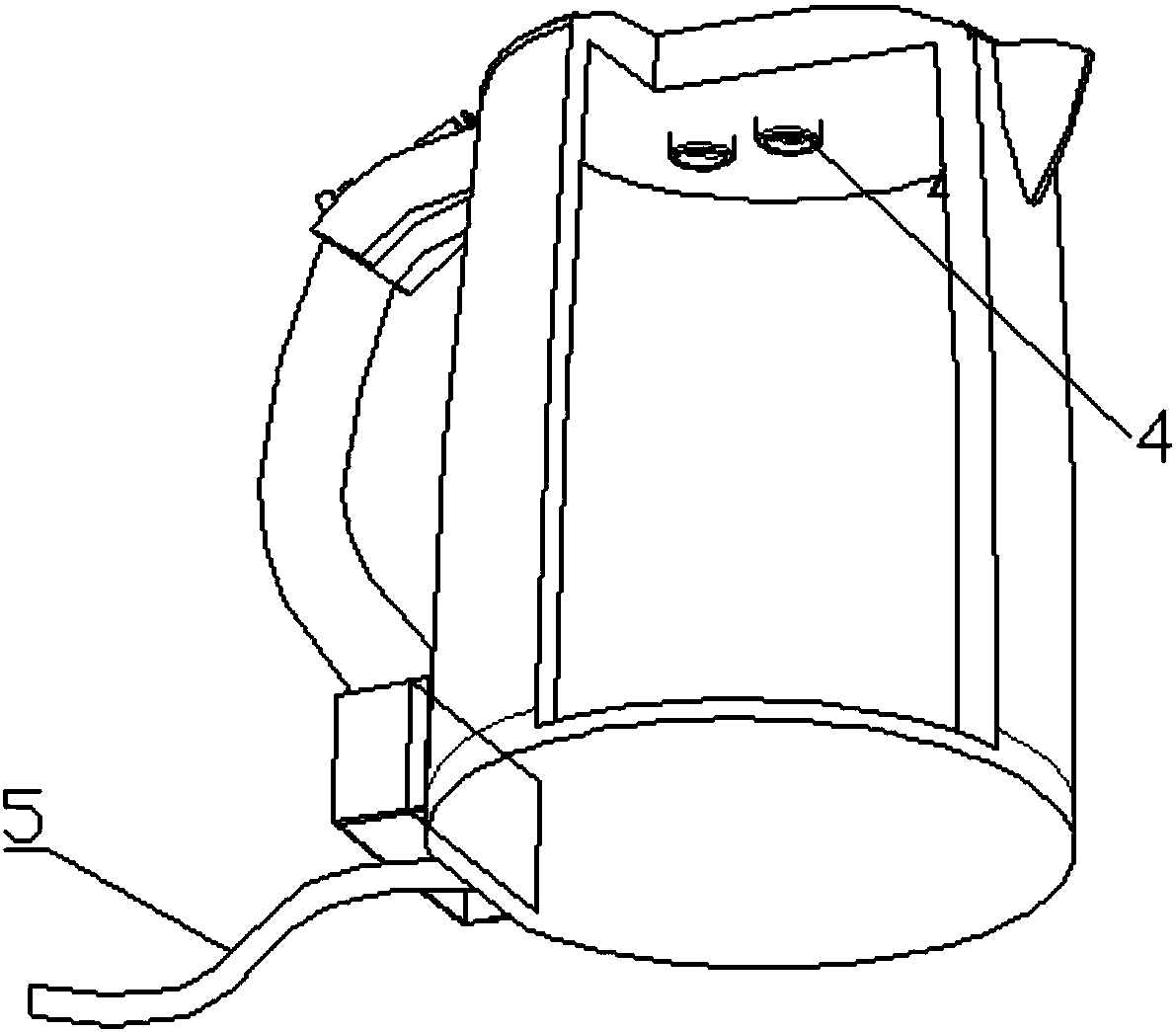

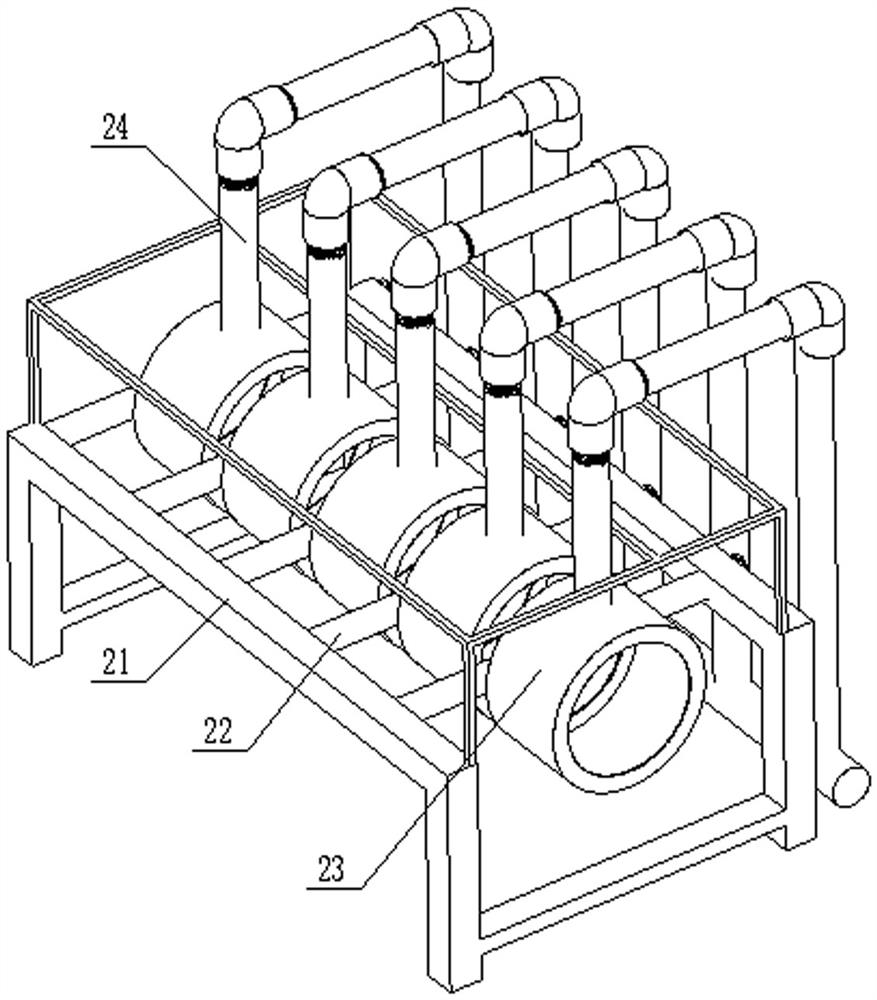

Multifunctional reaction kettle for chemical production

ActiveCN107597047AStir wellIncrease productivityDispersed particle filtrationChemical/physical/physico-chemical stationary reactorsSlagReducer

The invention discloses a multifunctional reaction kettle for chemical production. The multifunctional reaction kettle comprises a bottom box, wherein one side of the bottom of the inner wall of the bottom box is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a stirring device through a speed reducer; the top of the inner wall of the bottom box is fixedly connected with a second motor; an output shaft end of the second motor is fixedly connected with a gear; the surface of the gear is meshed with a slag removal device; one side of the top ofthe kettle body is communicated with a feed pipe; the top of the kettle body is fixedly connected with a gas treatment box through a support frame; one side of the inner wall of the kettle body is fixedly connected with a liquid level sensor; the bottom of the inner wall of the kettle body is fixedly connected with a temperature sensor; a heating pipe is fixedly connected in the wall body of the kettle body. The invention relates to the field of chemical technology. The multifunctional reaction kettle for chemical production solves the problems of waste gas treatment, is harmless to environment and humankind, has high automation degree and ensures stable product quality.

Owner:常州新东化工发展有限公司

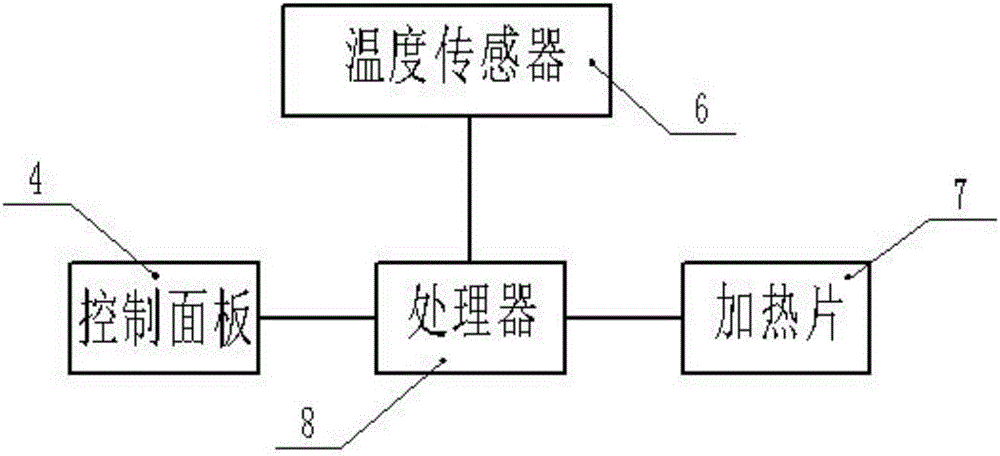

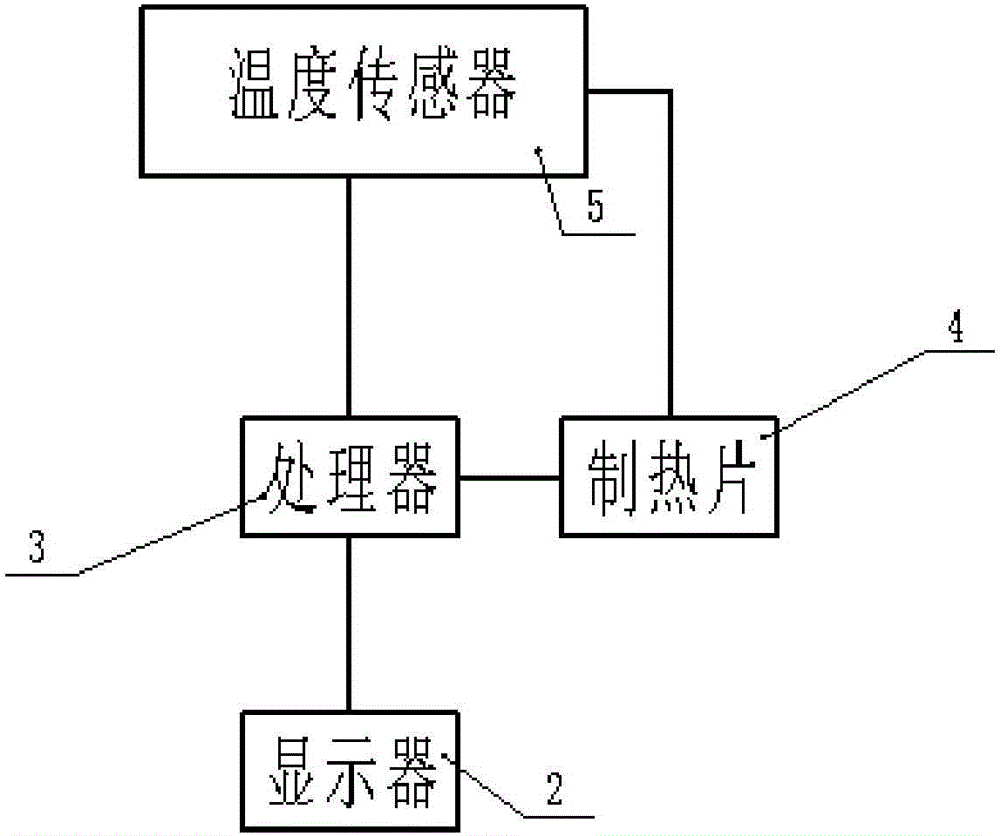

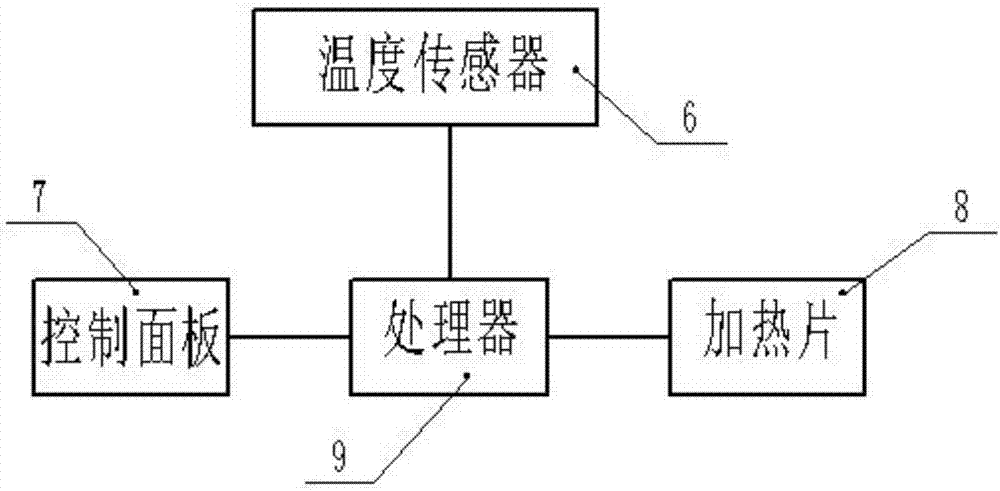

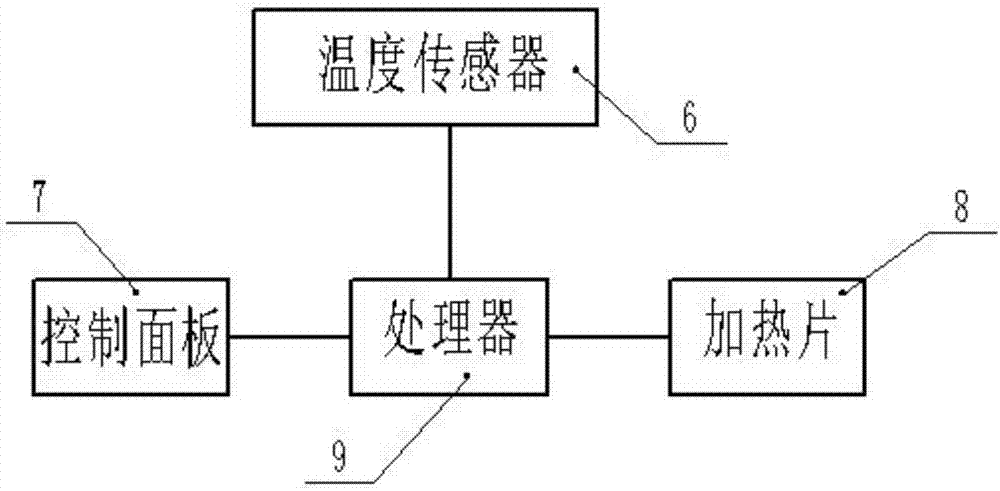

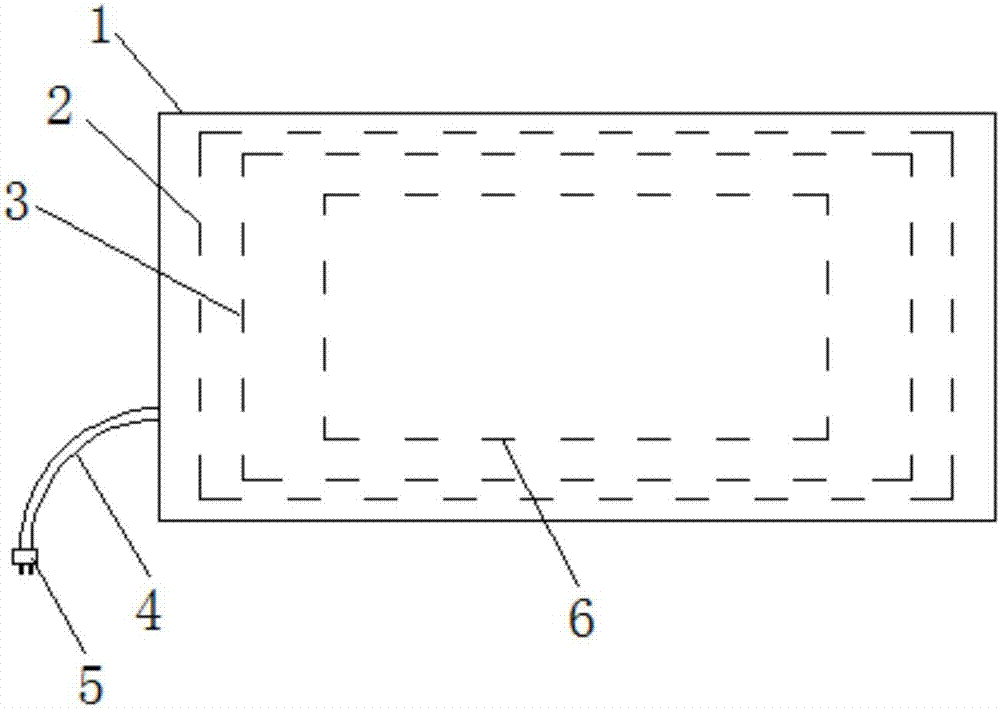

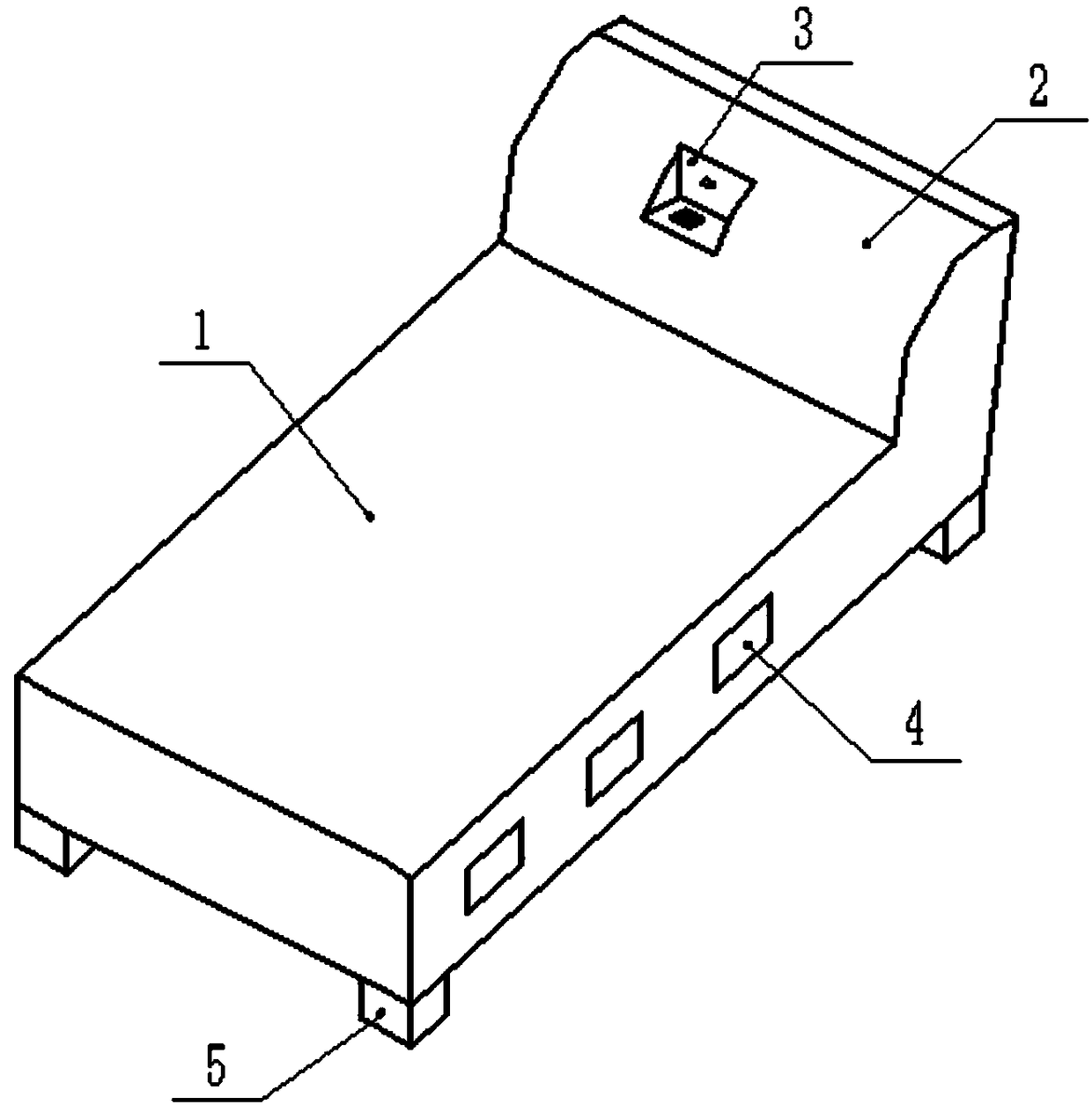

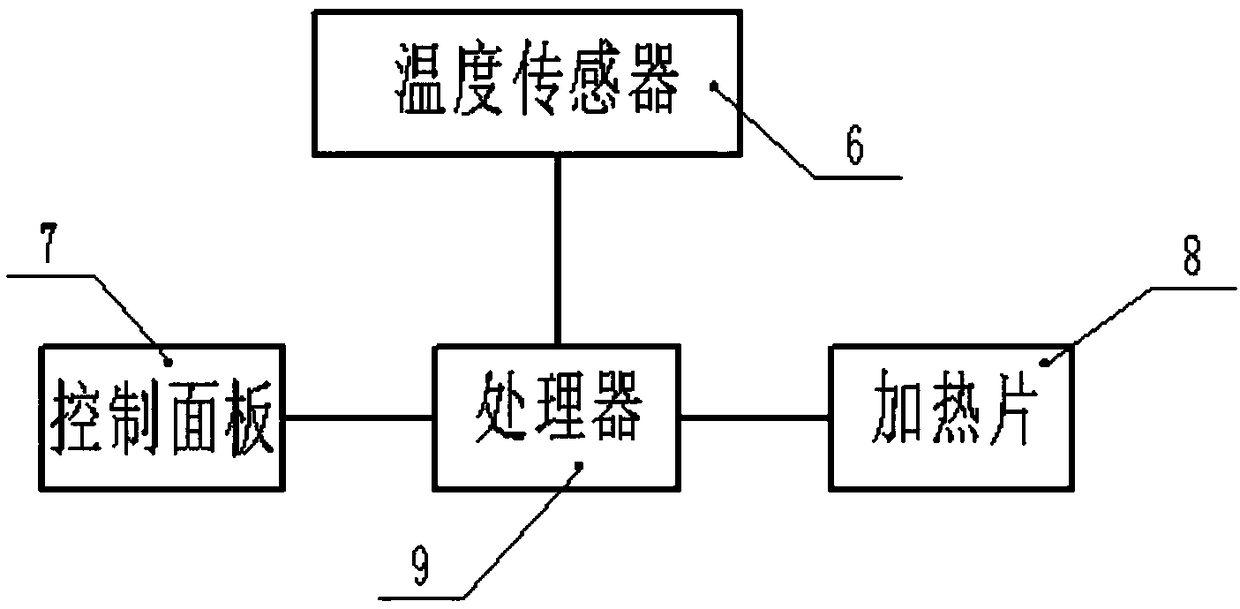

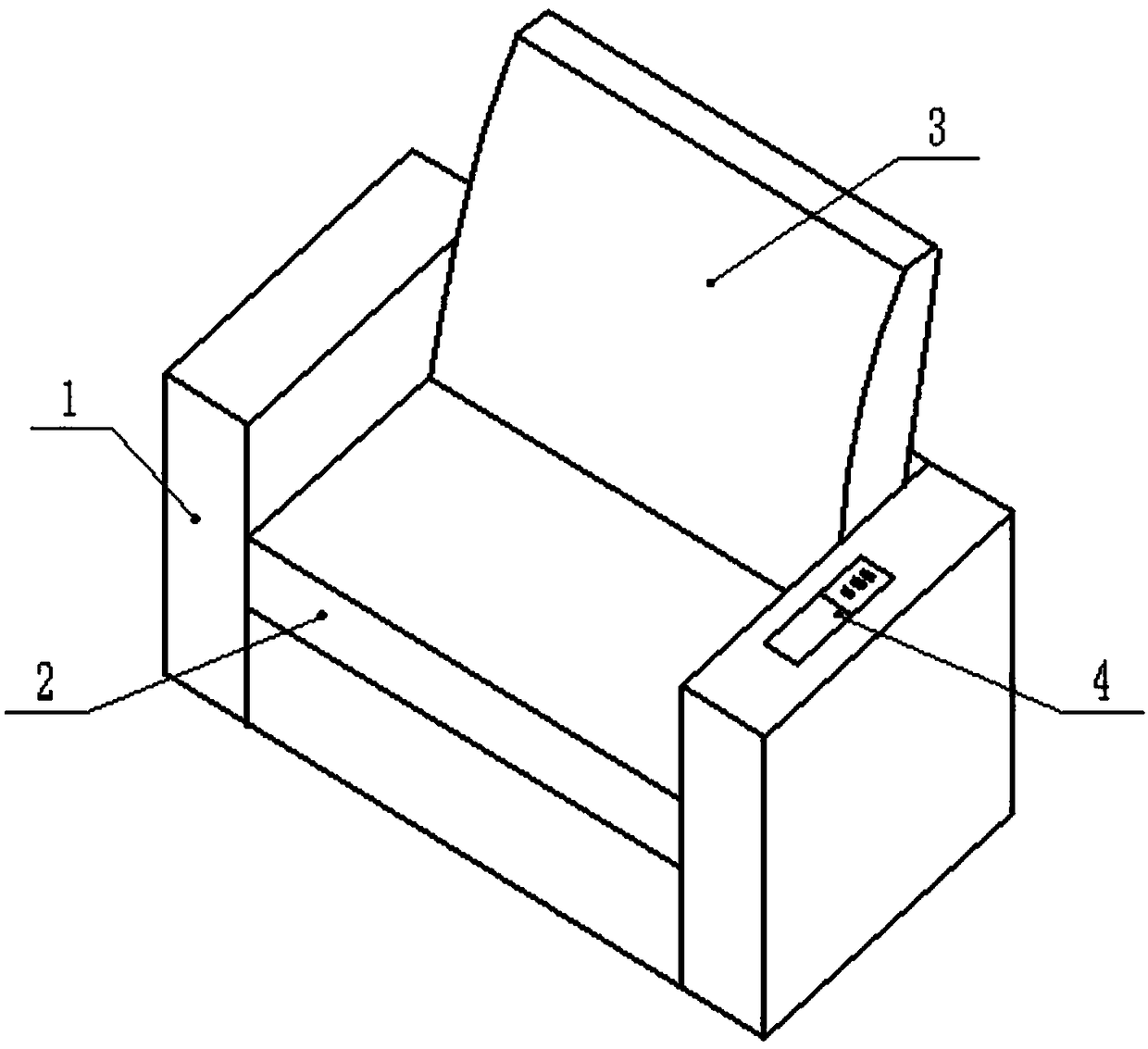

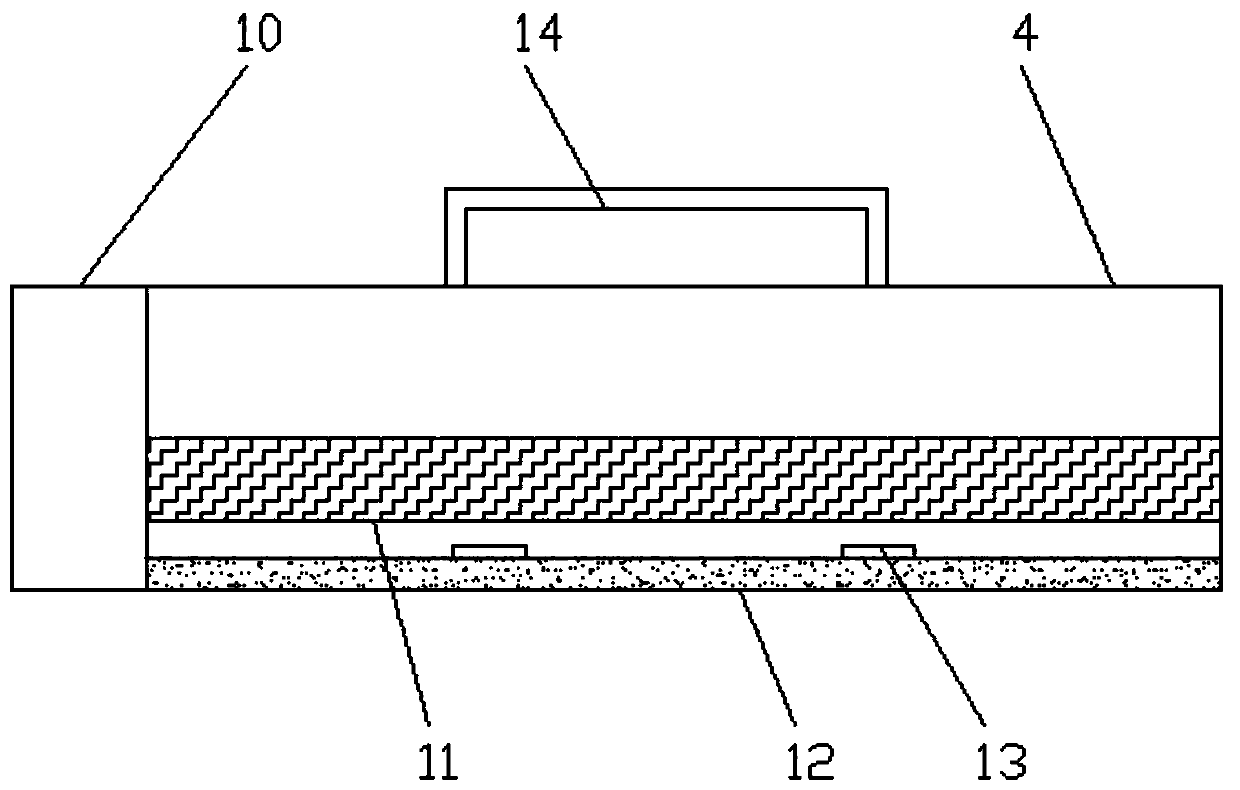

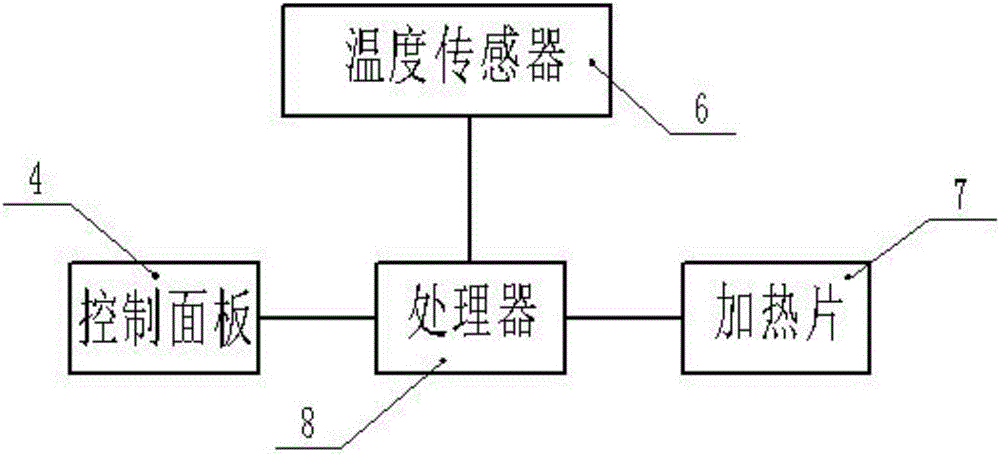

Sofa cushion

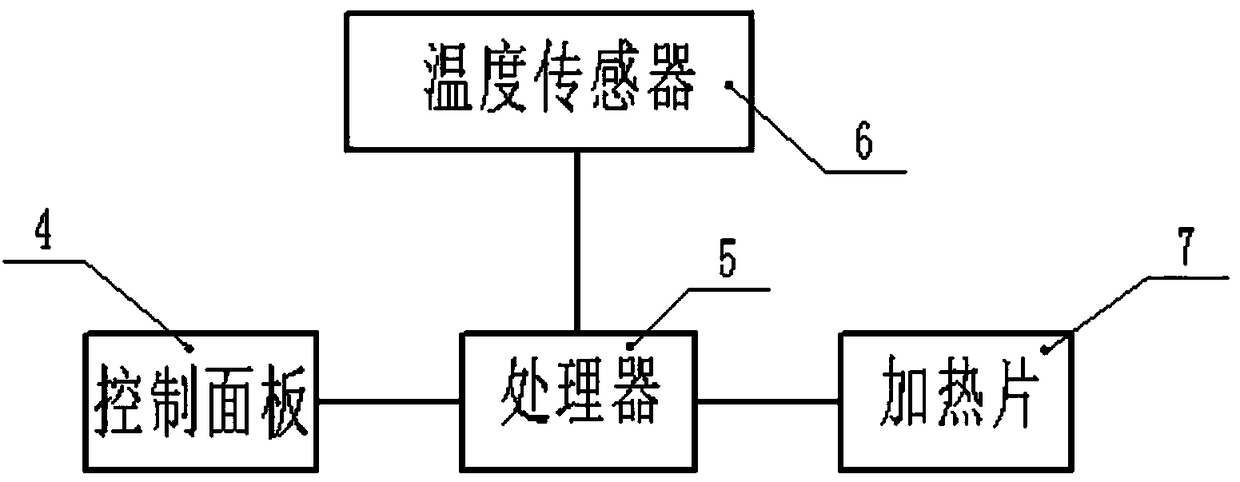

InactiveCN106419287ARealize the heating functionReal-time monitoring of heating temperatureStuffed mattressesSpring mattressesDisplay deviceEngineering

The invention discloses a sofa cushion which comprises a cushion body, a processor, a heating plate, a temperature sensor and a display. The heating plate and the temperature sensor are arranged in the cushion body, the display is arranged on the outer surface of the cushion body, the processor is connected with the heating plate, the temperature sensor and the display, and the temperature sensor is connected with the heating plate. The sofa cushion has the advantages that heat can be generated by the sofa cushion, and accordingly the sofa cushion is particularly suitable to be used in cold days and can bring great convenience for people in life.

Owner:湖南善林轩信息技术有限公司

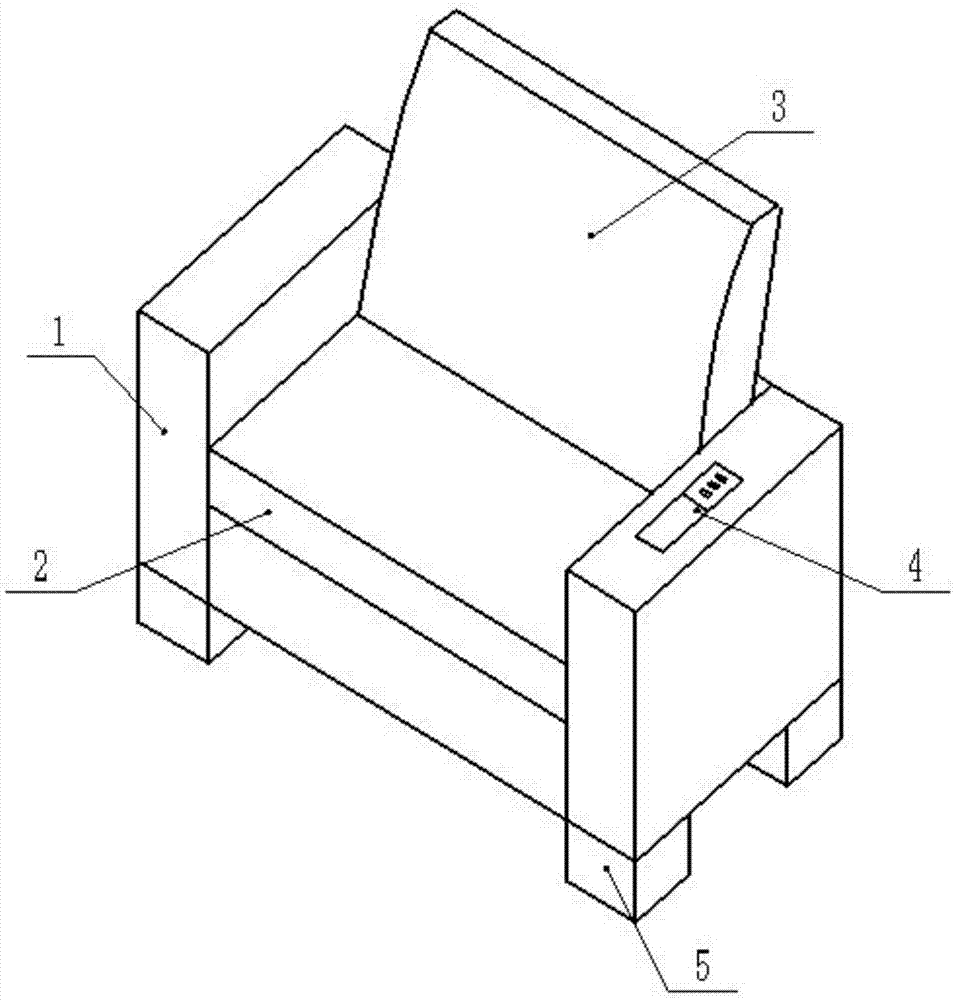

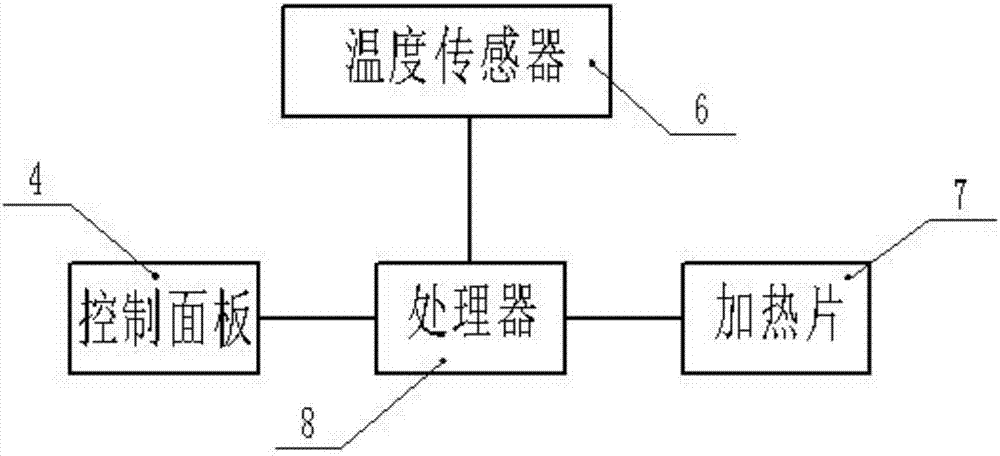

Health care sofa

The invention diclsoes a health care sofa. The health care sofa comprises a sofa seat; a seat cushion and a backrest are arranged on the sofa seat; a processor and a control panel are arranged on the sofa seat; a display screen, a jack, and a plurality of buttons are arranged on the control panel; a heating sheet and a temperature sensor are arranged in the seat cushion; a heating sheet and a temperature sensor are arranged in the backrest; the processor is connected with the heating sheets, the temperature sensors, the display screen, and the buttons respectively; each of the four corners of the bottom of the sofa seat is fixedly provided with a pedestal. The health care sofa is high in functionality, is convenient to use, and is capable of satisfying ever-increasing demands of people.

Owner:湖南海裕信息科技有限公司

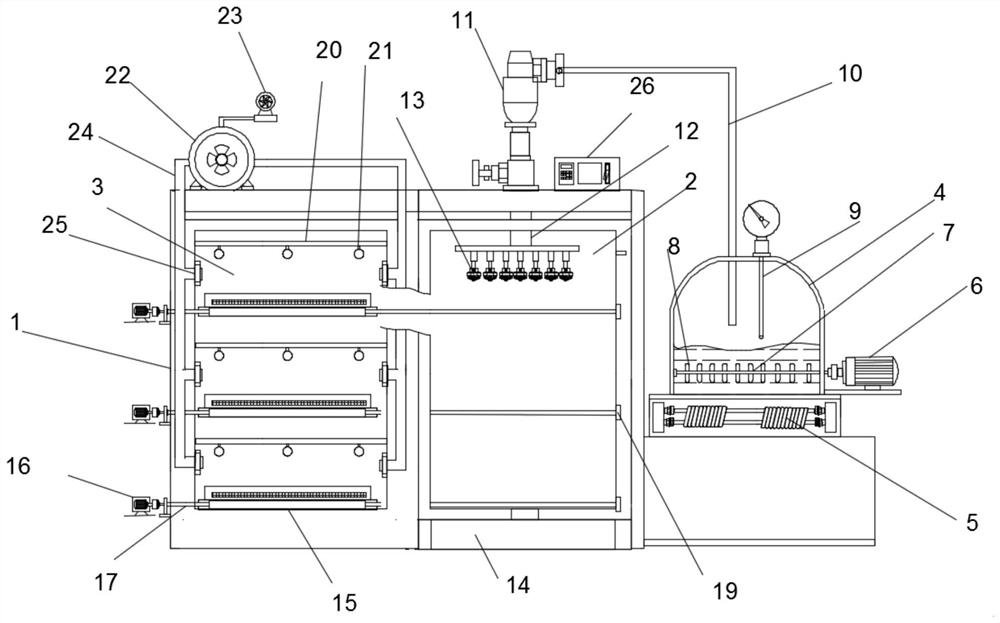

Environment-friendly circulating agricultural seed cultivation device

InactiveCN113228876AGood buddingImprove germination rateClimate change adaptationSpraying apparatusAgricultural scienceElectric machine

The invention relates to the technical field of cultivation devices, and discloses an environment-friendly circulating agricultural seed cultivation device, which comprises a device body. An operation chamber is arranged in the device body, a cultivation chamber is arranged on one side of the operation chamber, a nutrient solution box is arranged outside the operation chamber, an electric heating wire is arranged at the bottom of the nutrient solution box, and a first motor is arranged on one side of the nutrient solution box. One end of the first motor is connected with a stirring shaft, stirring paddles are arranged on the peripheral side of the stirring shaft, a thermometer is arranged in the nutrient solution box, a liquid conveying pipe is arranged outside the nutrient solution box, and one end of the liquid conveying pipe is connected with a pump body. According to the environment-friendly circulating agricultural seed cultivation device, by arranging a nutrient solution heating and stirring structure, the uniformity of the heating temperature of a nutrient solution is improved, traditional electric heater heating is replaced by blowing-in air flow heating, the uniformity of the cultivation temperature is guaranteed, and by arranging an auxiliary lighting device, light supplementing and lighting are conducted. Photosynthesis of seeds is promoted, and seed growth is accelerated.

Owner:江苏丰庆种业科技有限公司

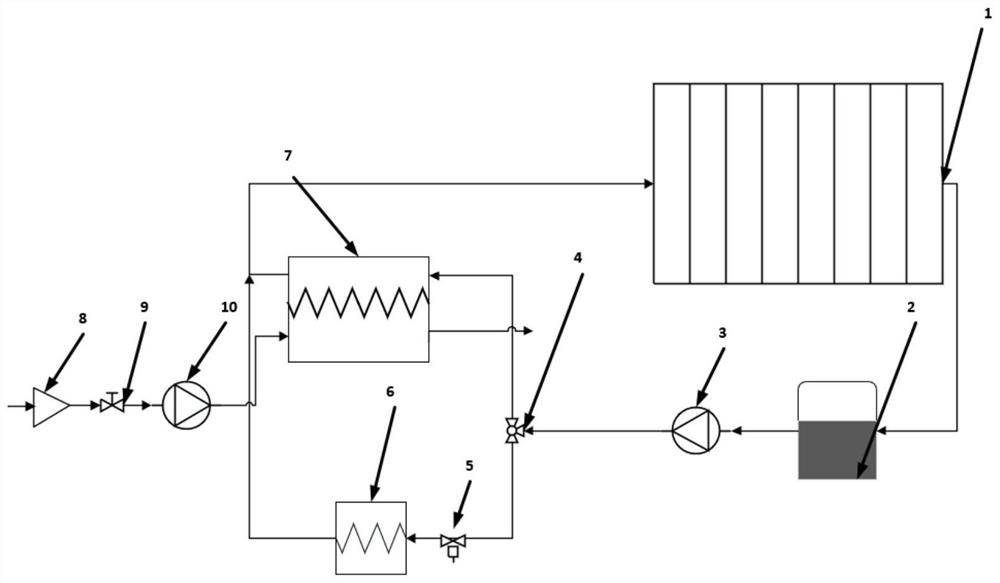

Ship cabin heating system taking fuel cell cooling water as heat source

InactiveCN112678139AWorking temperature is suitableImprove performanceAuxillariesPropulsion power plantsFuel cellsEngineering

The invention provides a ship cabin heating system taking fuel cell cooling water as a heat source. The ship cabin heating system comprises a fuel cell cooling loop, a heating pipeline and an external water passage, the fuel cell cooling loop is respectively connected with the external water passage and the heating pipeline; a fuel cell and a second convection heat exchanger are arranged in the fuel cell cooling loop, and after the fuel cell operates, discharged heat dissipation water is conveyed into the second convection heat exchanger and the heating pipeline; external water is conveyed into the second convection heat exchanger through the external water channel, exchanges heat with heat dissipation water and then is discharged into the external environment; and after the heat dissipation water conveyed into the heating pipeline supplies heat to the interior of the cabin, the heat dissipation water and the heat dissipation water subjected to heat exchange in the second convection heat exchanger are gathered into one path to be conveyed into the fuel cell. The system is energy-saving and environment-friendly, the waste heat of the cooling water of the fuel cell which is originally directly discharged is used for heating the ship, high-grade electric energy originally used for heating can be saved, fuel consumption is reduced, and the economy of the fuel cell ship is greatly improved.

Owner:DALIAN MARITIME UNIVERSITY

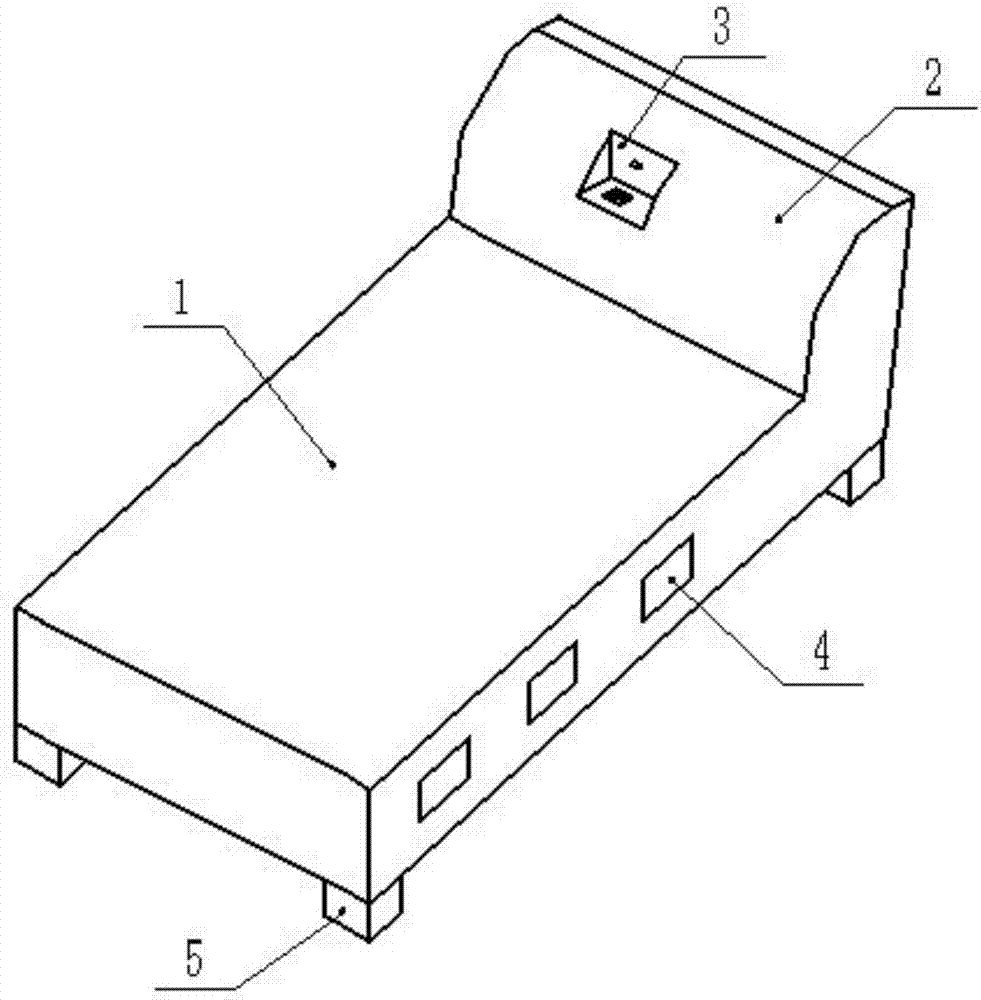

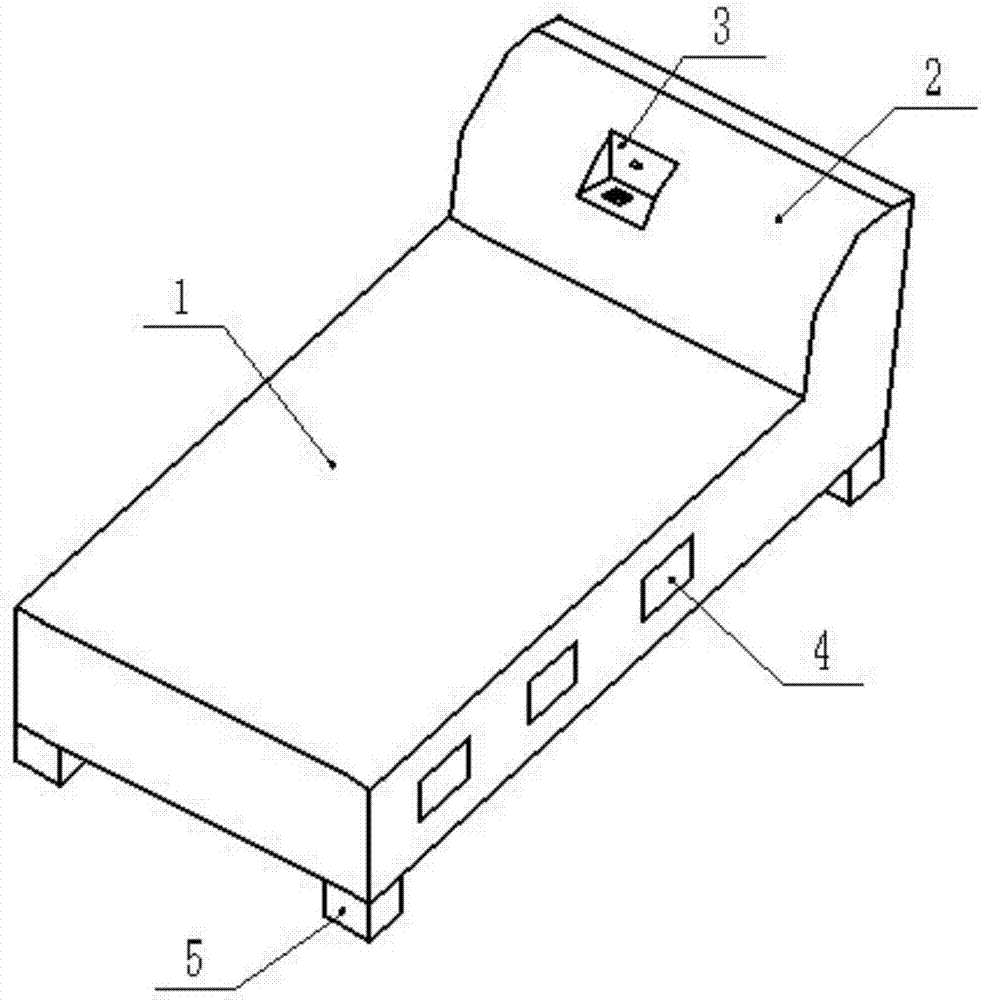

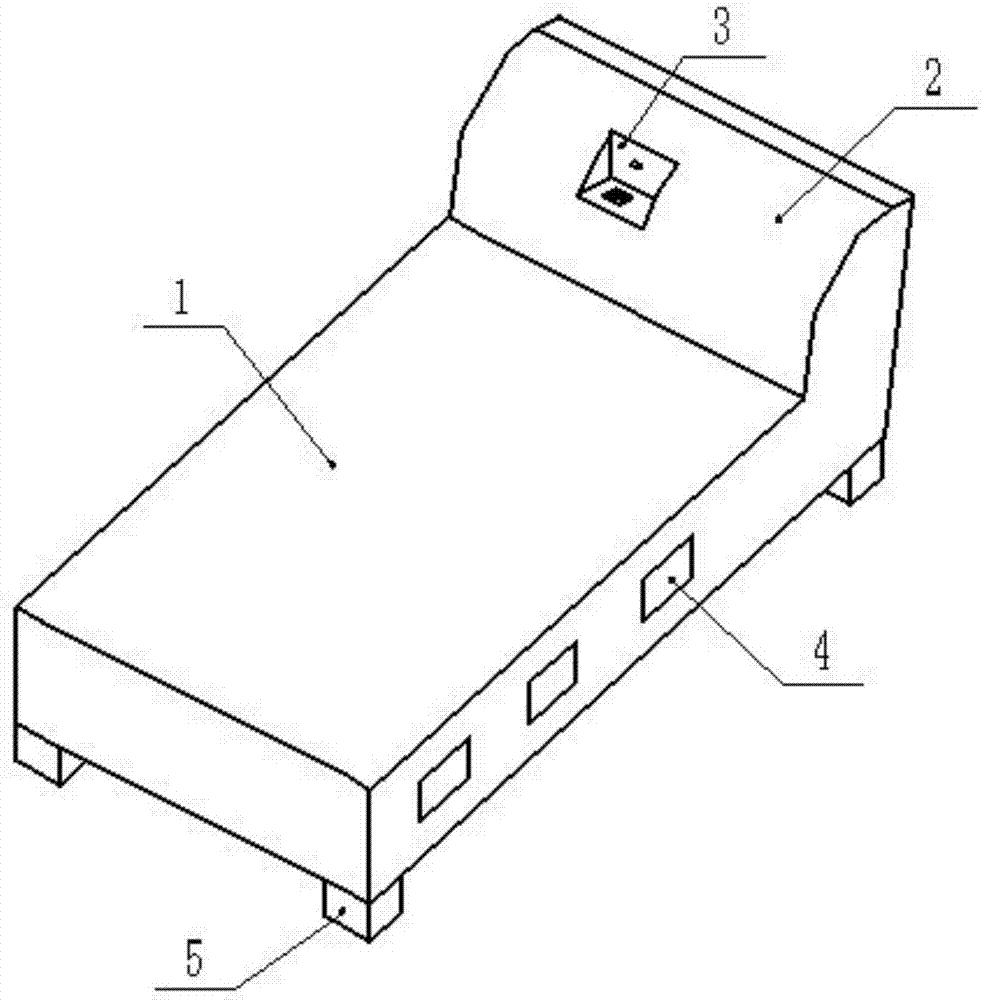

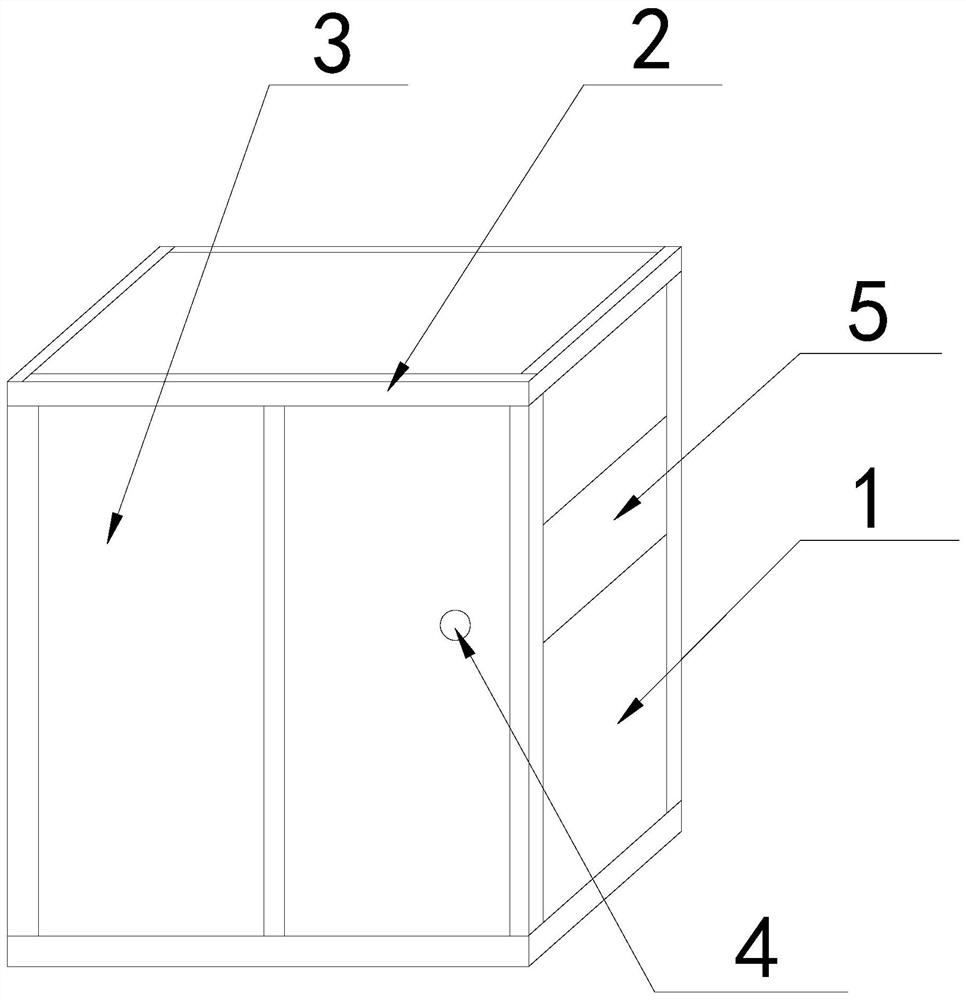

Home intelligent bed

The invention discloses a home intelligent bed, comprising a bed body and a head; a plurality of drawers are arranged on the lateral side of the bed body; the head is provided with a top in which a processor is arranged; a control panel is arranged on the top; the control panel is provided with a display screen, a jack and a plurality of keys; a mattress is arranged on the bed body; a heater and a temperature sensor are arranged in the mattress; the processor is connected to the heater, the temperature sensor, the display screen and the keys; a base is fixedly mounted at each of the four bottom corners of the bed body. The home intelligent bed has great functionality, is convenient to use and meets the increasing demands of people.

Owner:湖南海裕信息科技有限公司

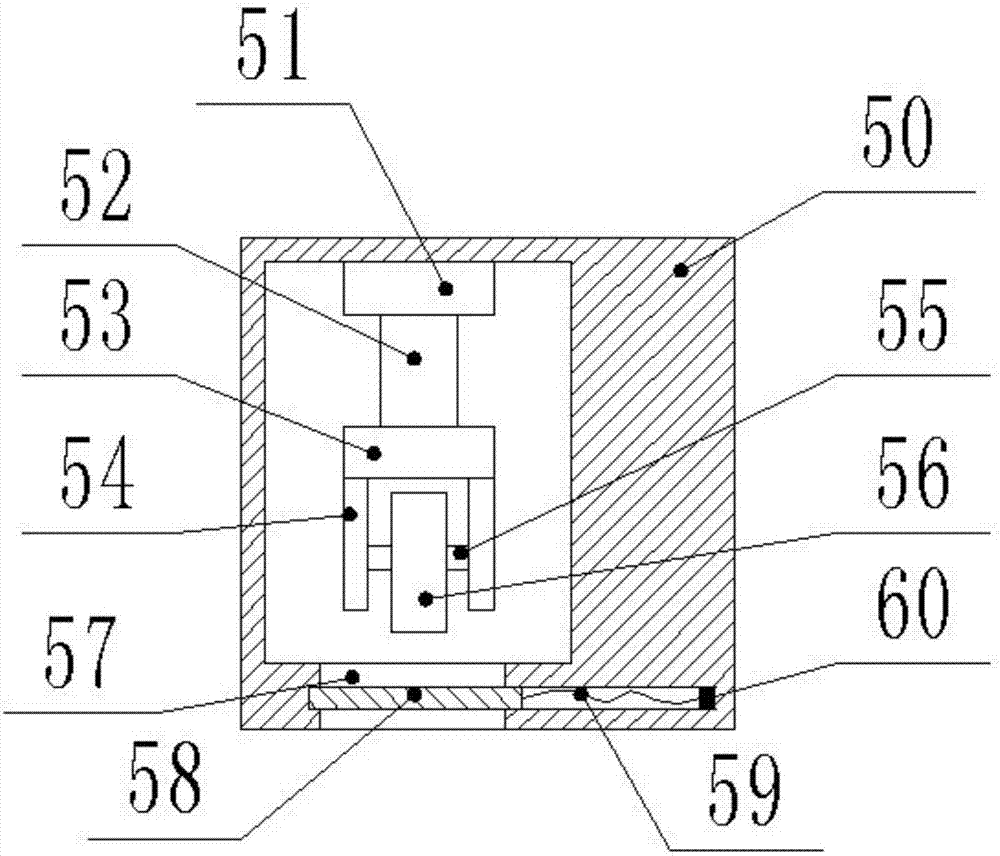

Bed which is designed for domestic use, and can be adjusted conveniently

InactiveCN106942940AFunctionalEasy to useStuffed mattressesAuxillary controllers with auxillary heating devicesEngineering

The invention discloses a bed which is designed for domestic use, and can be adjusted conveniently. The bed comprises a bed body and a bed head; the side surfaces of the bed body are provided with a plurality of drawers; the bed head is provided with a platform; a processor is arranged in the platform; a control panel is arranged on the platform; a display screen, a socket, and a plurality of buttons are arranged on the control panel; a mattress is arranged on the bed body; heating sheets and temperature sensors are arranged in the mattress; the processor is connected with the heating sheets, the temperature sensors, the display screen, and the buttons respectively; each of the four corners of the bottom of the bed body is fixedly provided with a pedestal. The functionality of the bed is excellent; and the bed is convenient to use, and is capable of satisfying the ever-increasing demands of people.

Owner:湖南海裕信息科技有限公司

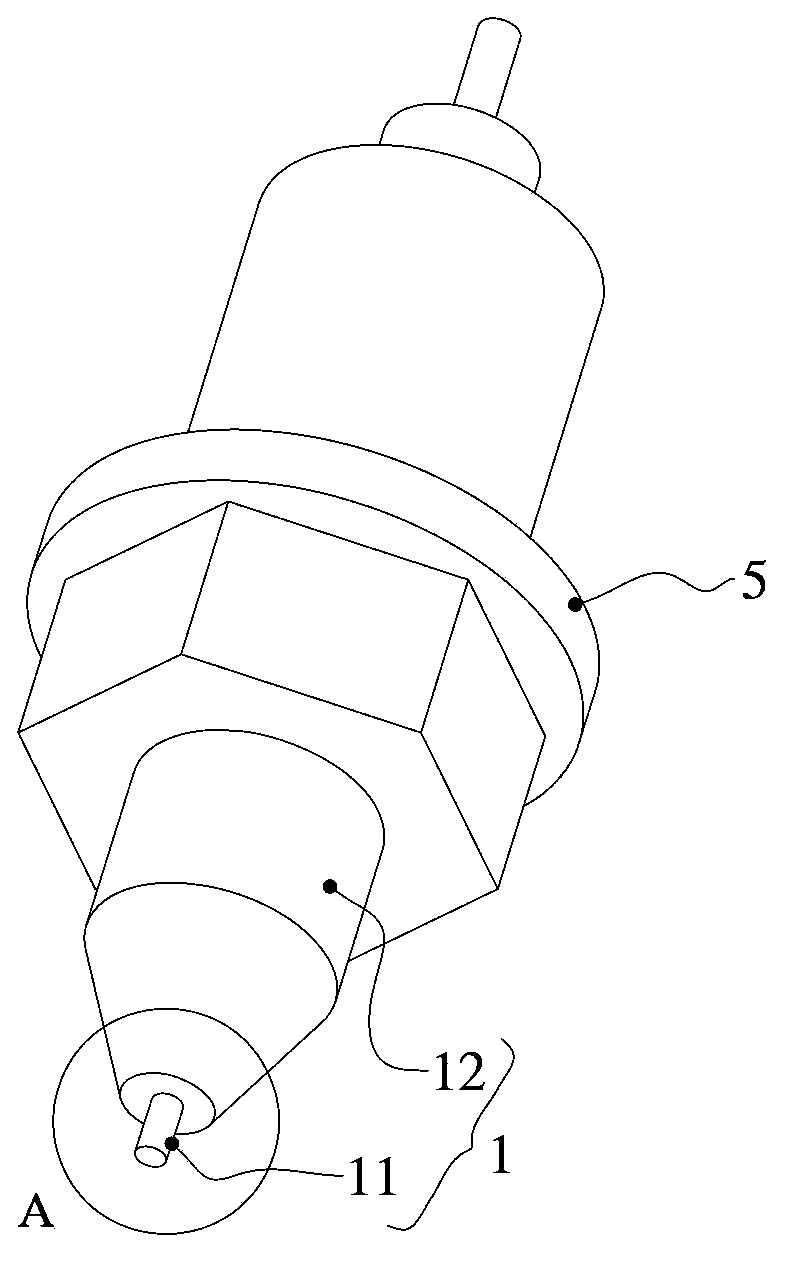

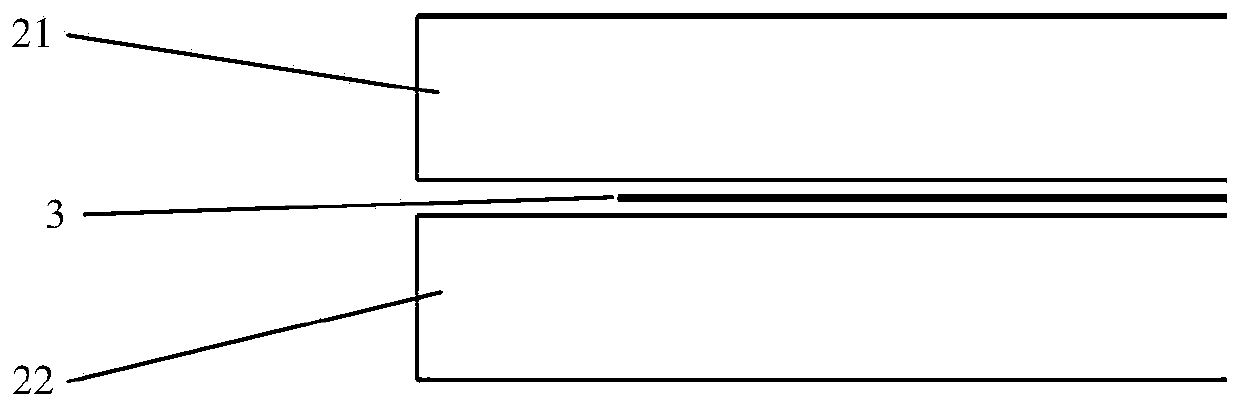

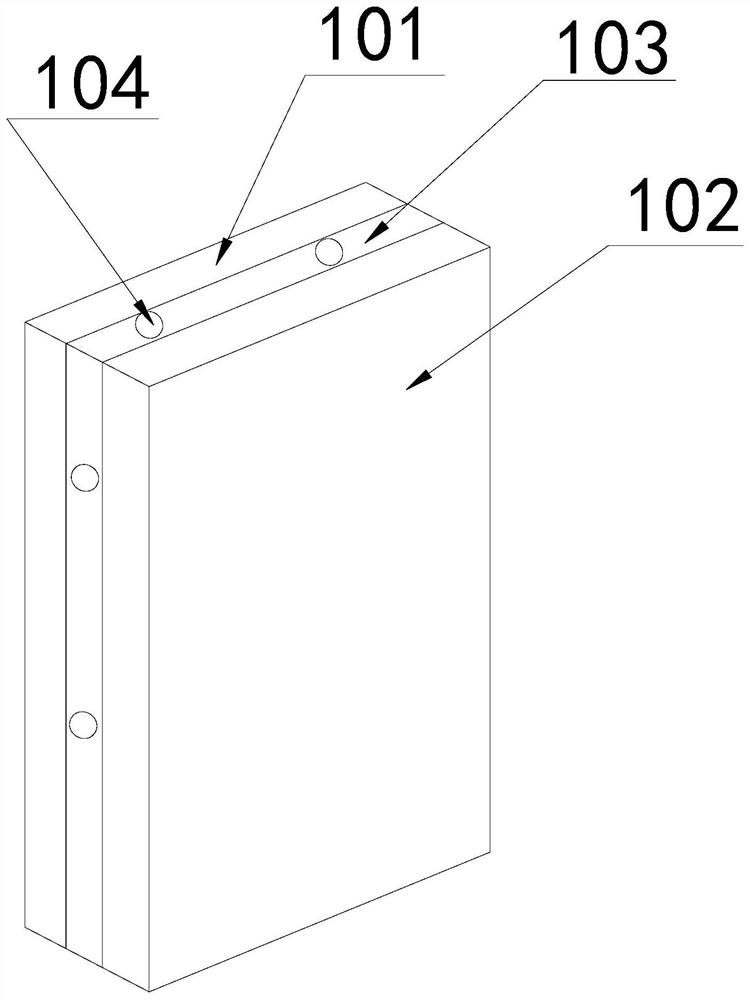

Anode-cathode connector and connector device for battery or capacitor

InactiveCN103969473AAvoid damageGuarantee product qualityMeasurement instrument housingTest batteryElectrical battery

The invention belongs to the technical field of electronic component test, and particularly relates to an anode-cathode connector and a connector device for a battery or a capacitor. The connector comprises a metal portion for on detection of an anode and a cathode of the battery or the capacitor, the metal portion is provided with a heat sensor used for detecting heating temperature of the connector, and the heat sensor is embedded, integrated or attached onto the connector. The connector device comprises a fixed frame and a moving frame spaced from the fixed frame, and the battery or capacitor anode-cathode connectors matched mutually are disposed on the fixed frame and the moving frame respectively. By the aid of the heat sensor arranged on the connector, when the battery or the capacitor is tested by test equipment, heat value on the connector can be monitored constantly, and accordingly the connector can be avoided from transferring heat to the battery or the capacitor to affect test precision; moreover, the battery or the capacitor can be protected from damage due to overheating, and product quality of the battery or the capacitor is guaranteed.

Owner:REPOWER TECH CO LTD

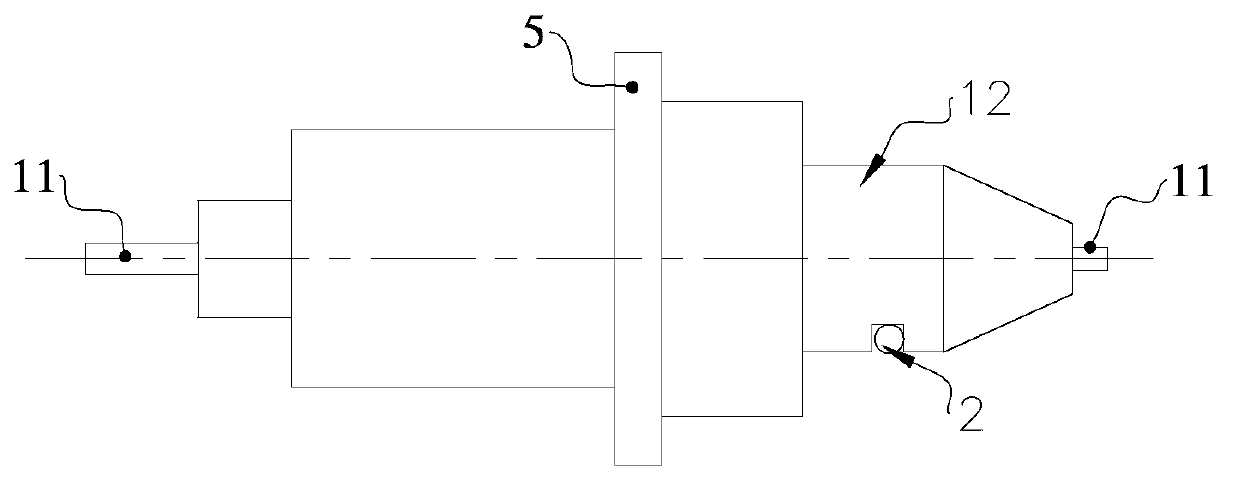

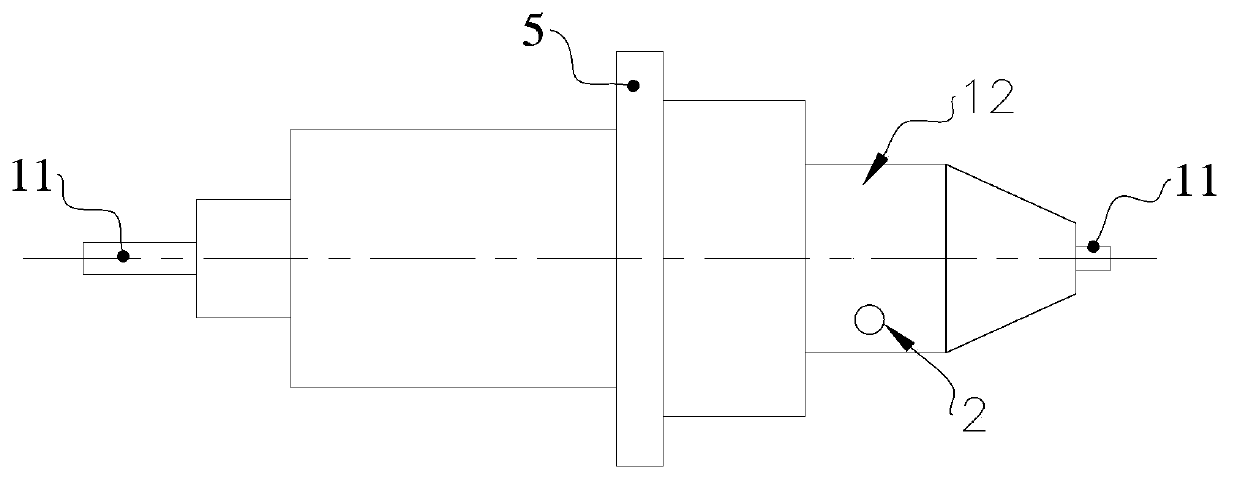

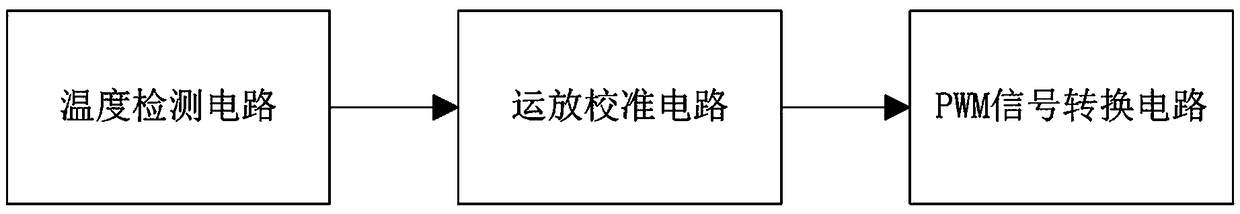

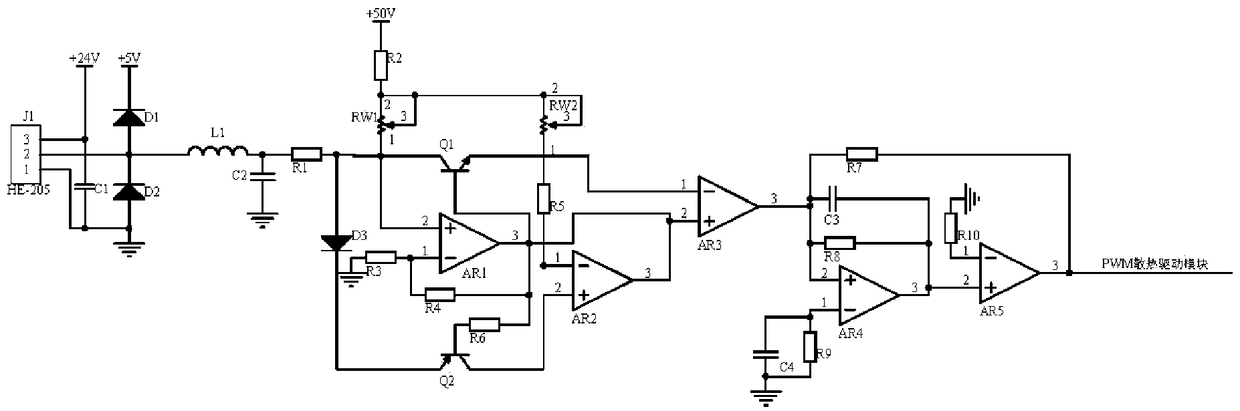

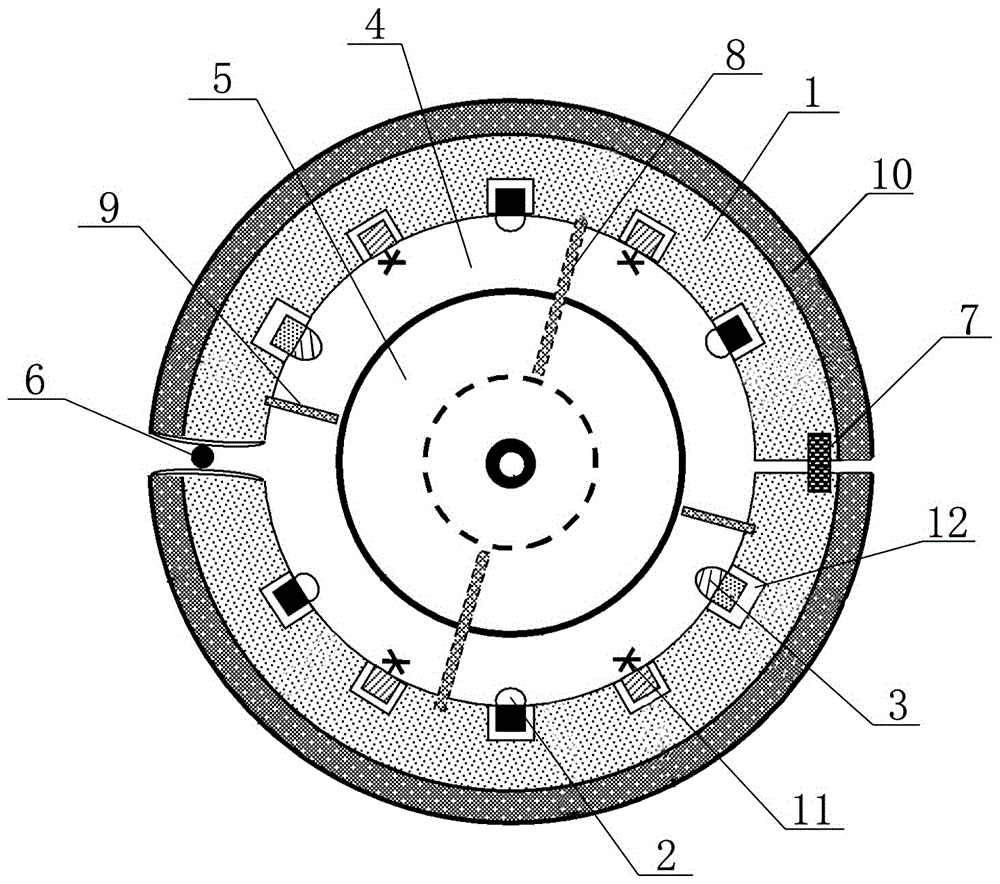

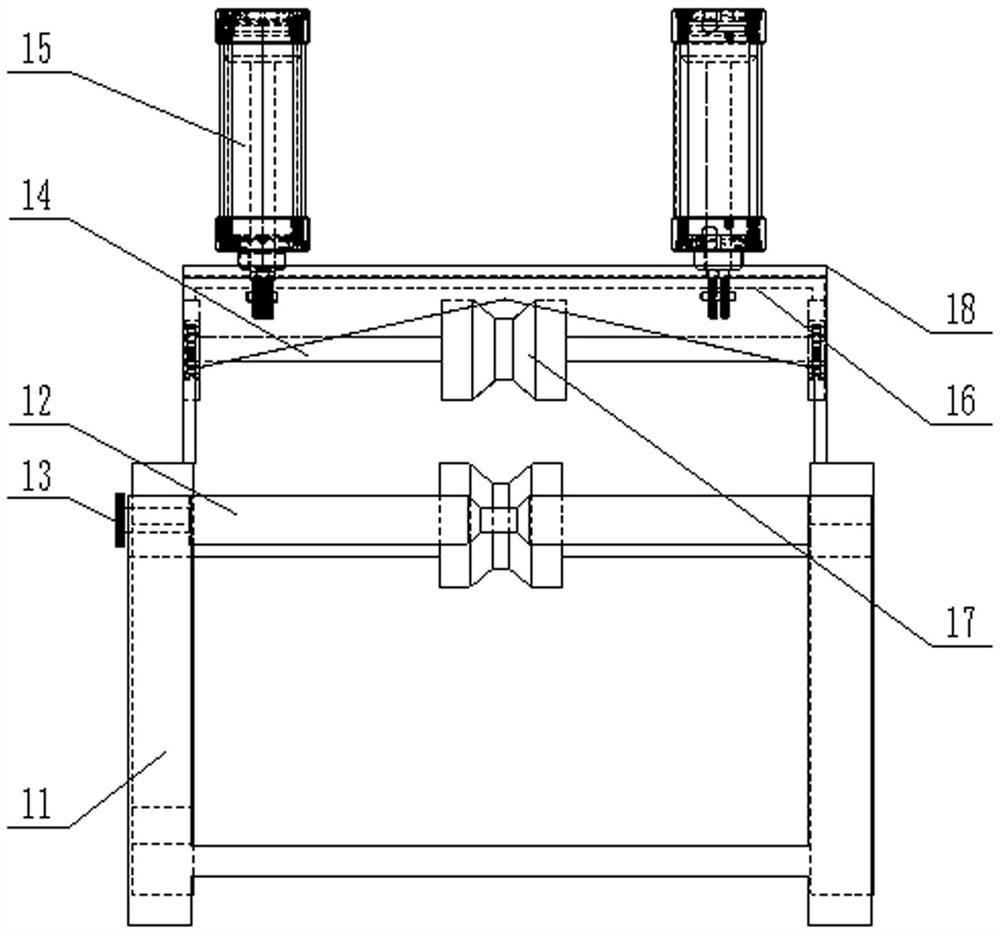

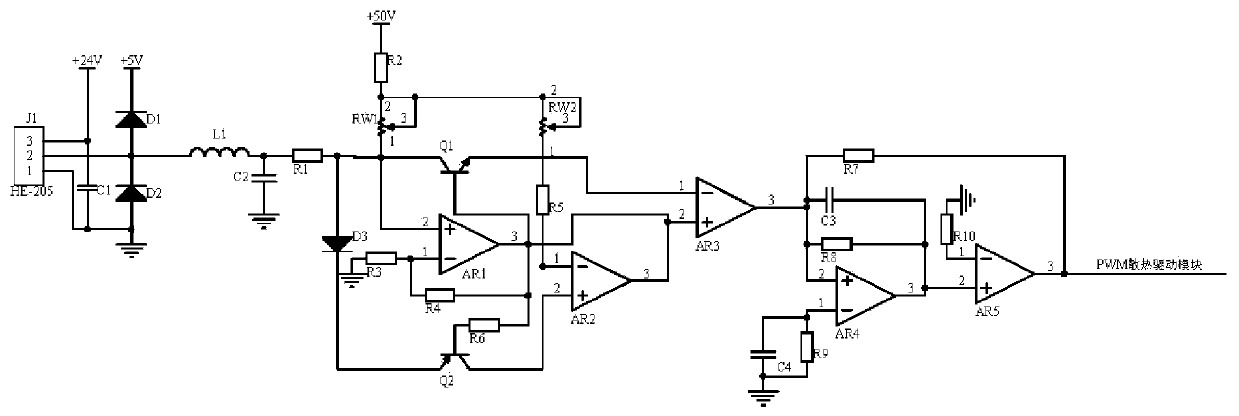

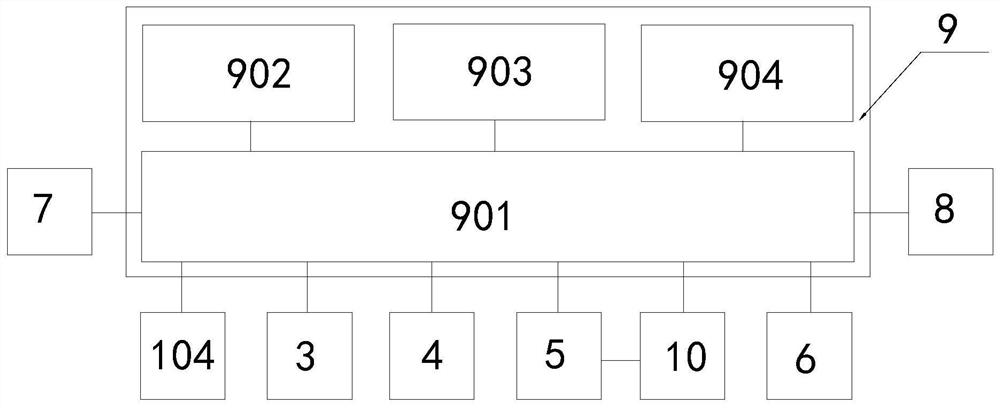

Power regulation circuit for motor radiating device of stamping robot

ActiveCN108879612AIngenious ideaReal-time monitoring of heating temperatureEmergency protective circuit arrangementsControl signalComputer module

The present invention discloses a power regulation circuit for a motor radiating device of a stamping robot. The circuit comprises a temperature detection circuit, a voltage stabilization calibrationcircuit and a PWM signal conversion circuit. The temperature detection circuit detects a heating temperature of a servo motor in real time when a stamping rotor works through an HE-205 infrared temperature measurement probe J1, the voltage stabilization calibration circuit employs an operational amplifier AR1, an operational amplifier AR2 and a variable resistor RW1 and a variable resistor RW2 toform a composite circuit to perform signal voltage stabilization processing, the signals are finally subjected to in-phase amplification through the operational amplifier AR3 and then input into a PWMsignal conversion circuit, and the PWM signal conversion circuit employs an operational amplifier AR4, an operational amplifier AR5, a capacitor C3 and a capacitor C4 to form a composite conversion circuit to convert voltage signals to PWM signals. The power regulation circuit can monitor the heating temperature of the servo motor in real time when the stamping robot works and can output accuratePWM control signals according to the temperature to drive the radiating driving module of the servo motor of the stamping robot to work.

Owner:肇庆市维特利机械科技有限公司

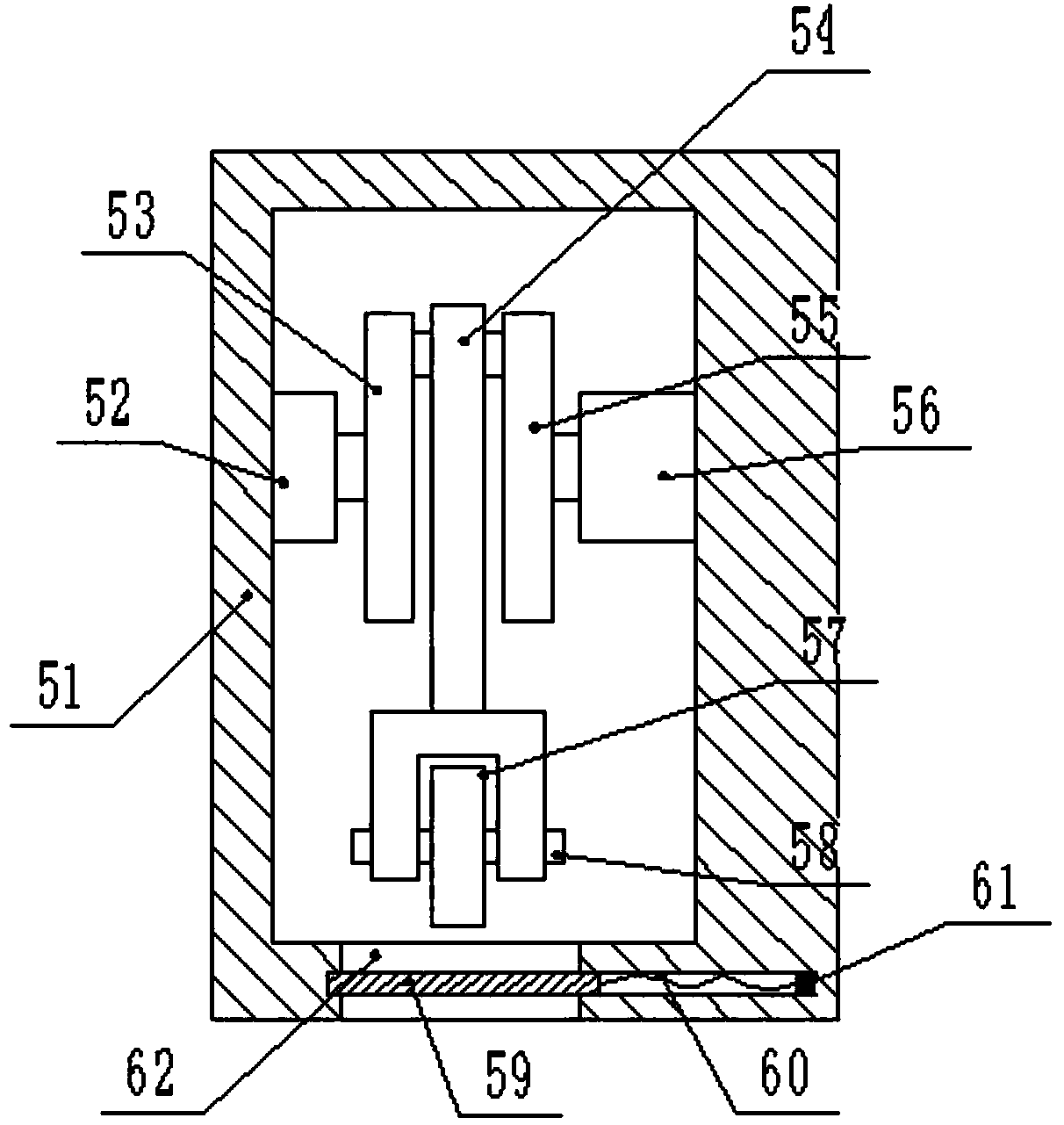

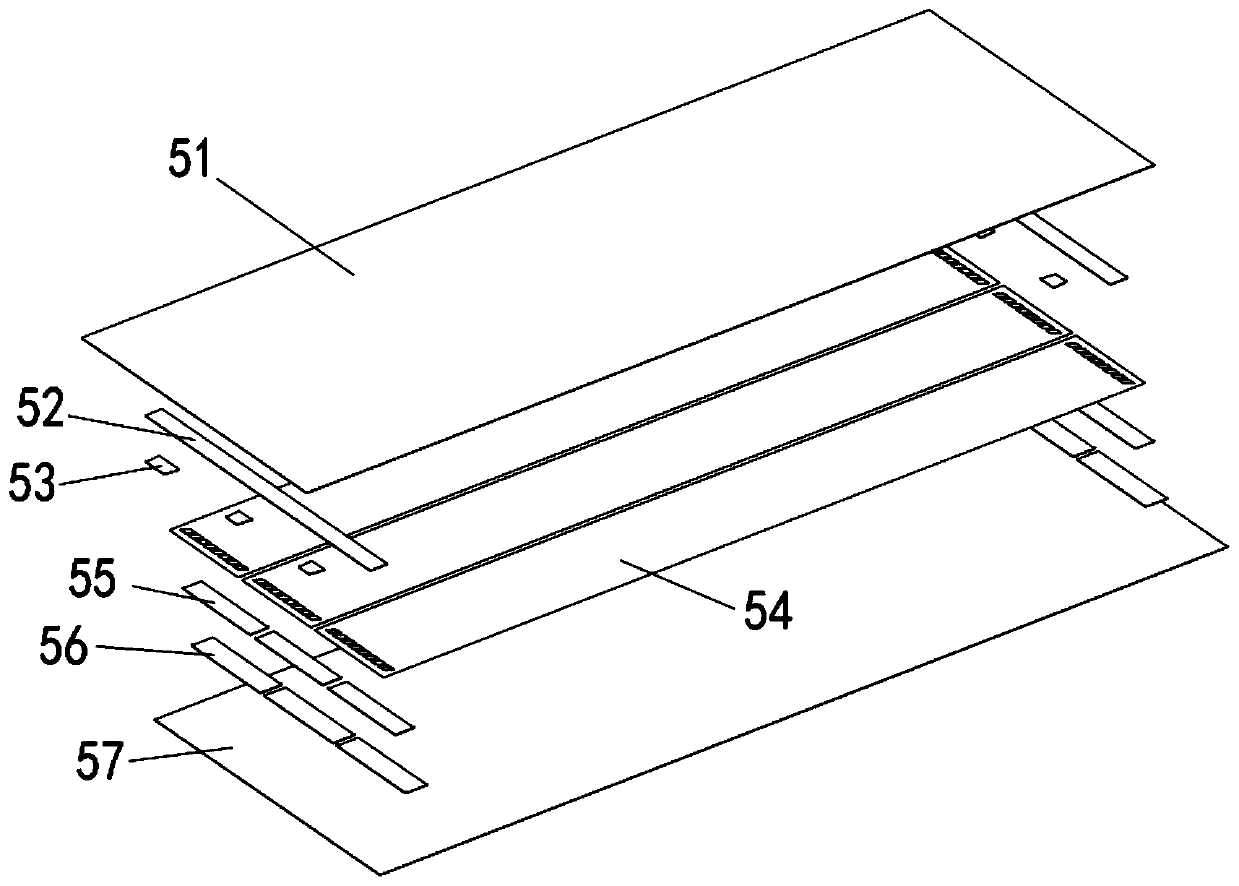

Carbon crystal heating electric heating painting

InactiveCN107143908AReal-time monitoring of heating temperatureAvoid damageLighting and heating apparatusElectric heating systemElectricityControl switch

The invention provides a carbon crystal heating electric heating painting. The electric heating painting comprises a shell, a carbon crystal heating plate and a monitoring unit. A panel layer is arranged on one side of the shell, and a baffle plate is arranged on the other side of the shell. The carbon crystal heating plate is located in the shell. The two sides of the carbon crystal heating plate are provided with a first heat preservation layer and a second heat preservation layer correspondingly. A charging unit is electrically connected with the carbon crystal heating plate and penetrates through the side face of the shell and is arranged outside the shell. An overheating protection unit is arranged on the charging unit. The monitoring unit is arranged in the shell, is in communication connection with the control unit and is used for monitoring the temperature in the shell and transmitting temperature information to a control unit. The control unit is electrically connected with the overheating protection unit and used for receiving the temperature information of the monitoring unit and controlling switching-on and switching-off of the overheating protection unit. By the adoption of the carbon crystal heating electric heating painting, the problem that due to the too high heating temperature, the heating plate is damaged or is on fire is effectively avoided.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Bed with storage drawers

The invention discloses a bed with storage drawers. The bed comprises a bed body and a bed head, wherein the side surface of the bed body is provided with a plurality of drawers; the bed head is provided with a countertop; the countertop is internally provided with a processor; a control panel is arranged on the countertop and provided with a display screen, a jack and a plurality of buttons; a mattress is arranged on the bed body and internally provided with a heating sheet and a temperature sensor; the processor is separately connected with the heating sheet, the temperature sensor, the display screen and the buttons; and pedestals are fixedly mounted on the four corners of the bottom of the bed body. The bed with storage drawers in the invention has strong functionality, is convenient to use, and meets the increasing demands of people.

Owner:湖南海裕信息科技有限公司

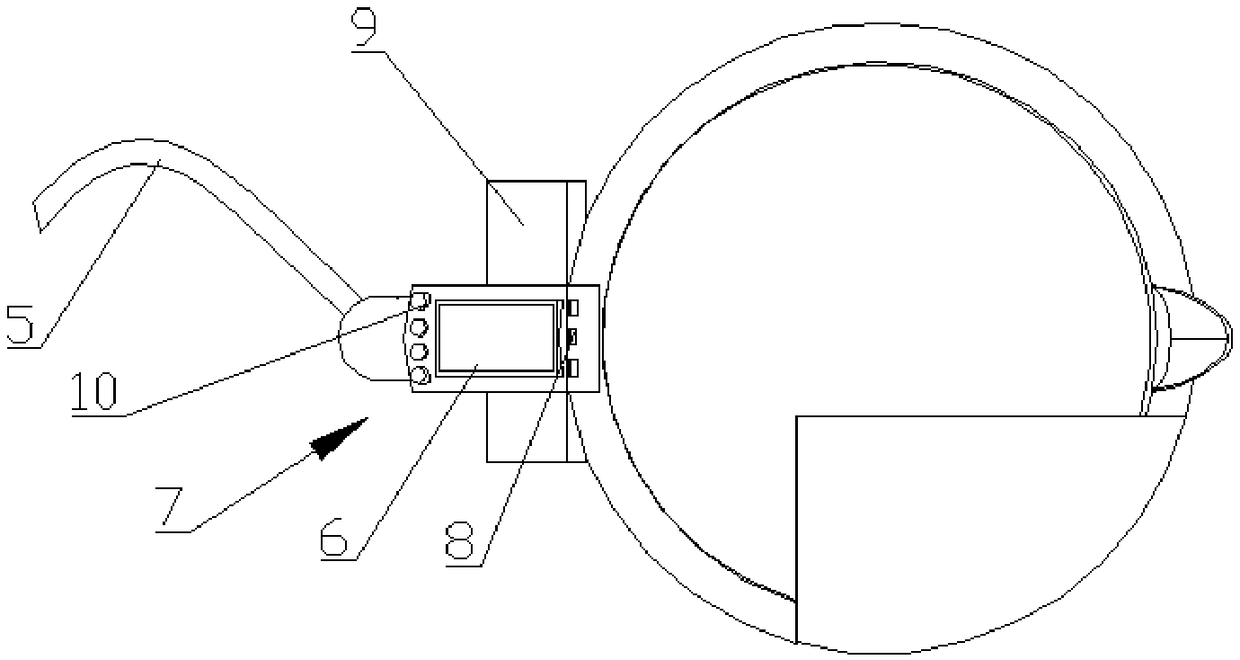

Novel power hot water bottle

PendingCN108107950AReal-time monitoring of heating temperatureIncrease heating safety factorAuxillary controllers with auxillary heating devicesUltrasonic sensorWater quality

The invention provides a novel power hot water bottle comprising a hot water bottle body. The hot water bottle body is fixedly provided with a CPU. The CPU is connected with an ultrasonic sensor usedfor detecting the height of the liquid surface, a TDS water quality sensor used for detecting the content of dissolved matter in liquid and an NTC temperature sensor used for temperature detection andoverheating protection. The CPU is connected with a human-computer interaction device. The human-computer interaction device includes a control device which is used for controlling the heating powerof the hot water bottle. The novel power hot water bottle of the invention has the advantages of controllable heating power, high safety coefficient, diverse application functions and smooth control.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

Sofa with socket

InactiveCN108567260ARealize the charging functionRealize the heating functionSofasCouchesEngineeringCushion

The invention discloses a sofa with a socket. The sofa comprises a sofa seat, wherein the sofa seat is provided with a seat cushion, a backrest, a processor and a control panel; the control panel is provided with a display screen, a jack and a plurality of buttons; the seat cushion and the backrest are each provided with a heating sheet and a temperature sensor; and the processor is separately connected with the heating sheet, the temperature sensor, the display screen and the buttons. The sofa with the socket of the invention has strong functionality, is convenient to use, and meets the increasing demands of people.

Owner:湖南海裕信息科技有限公司

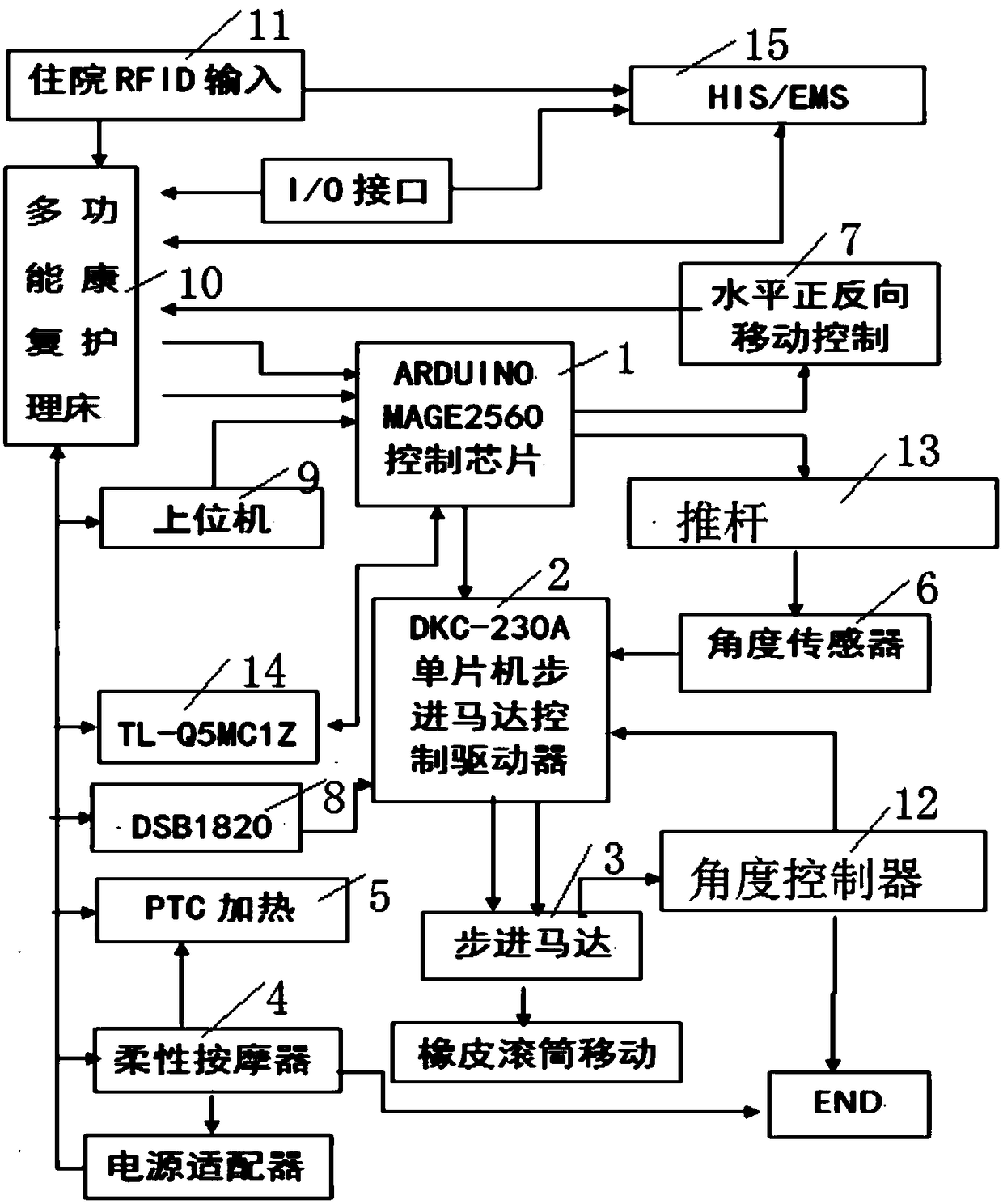

Multifunctional rehabilitation nursing bed with artificial intelligence

PendingCN109172180AReduce work intensityReal-time monitoring of PTC heating temperature in running stateDiagnosticsNursing bedsBed-riddenRehabilitation nursing

The invention relates to a multifunctional rehabilitation nursing bed with artificial intelligence, comprising a main control chip, a stepping motor control driver, a stepping motor, a massager, a heater, an angle sensor, a controller, a temperature sensor, a host computer, a rehabilitation nursing bed, an angle controller for controlling the angle sensor, a push bar cooperated with the angle controller, a proximity switch, a hospital information system and an RFID nursing card; the stepping motor control driver is connected with the stepping motor. The stepping motor controls the driver to drive the stepping motor, the push bar is connected with the stepping motor, and the push bar is controlled by the stepping motor. The RFID nursing card is fixedly installed on the rehabilitation nursing bed or worn on the patient and communicates with the hospital information system through wireless connection. The invention can realize real-time monitoring, and all the equipment installed on the rehabilitation bed has the advantages of lower overall design cost, multiple functions, high reliability, high practicability, and can meet the popularization and application of high-quality nursing care for long-term bed-ridden patients.

Owner:SHANGHAI PUDONG NEW AREA PEOPLES HOSPITAL

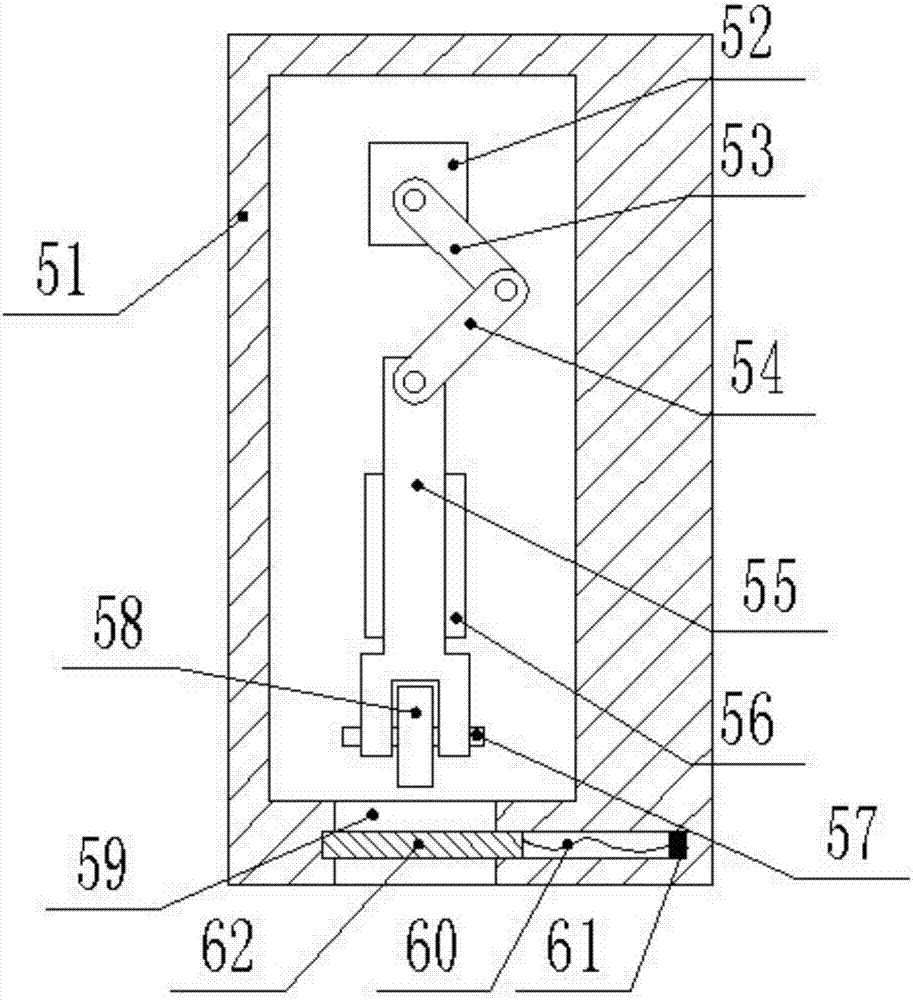

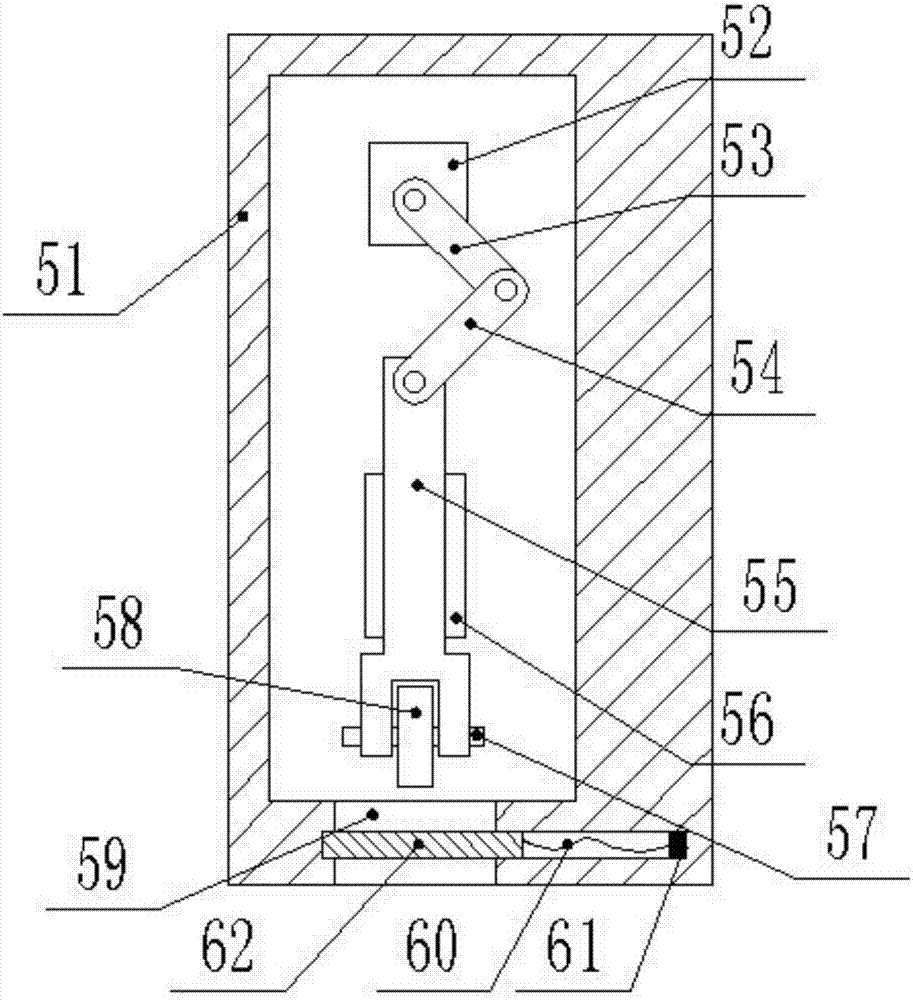

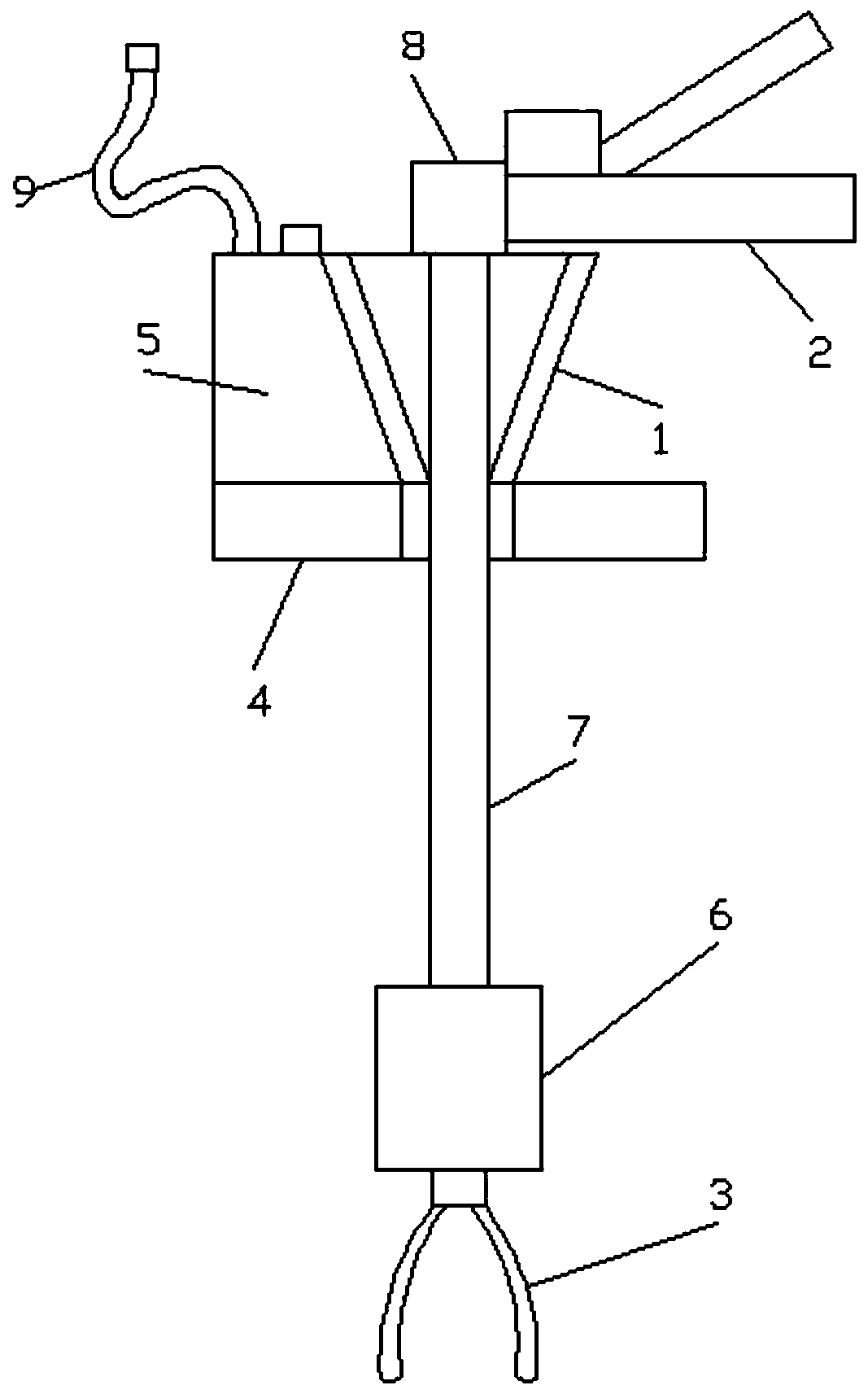

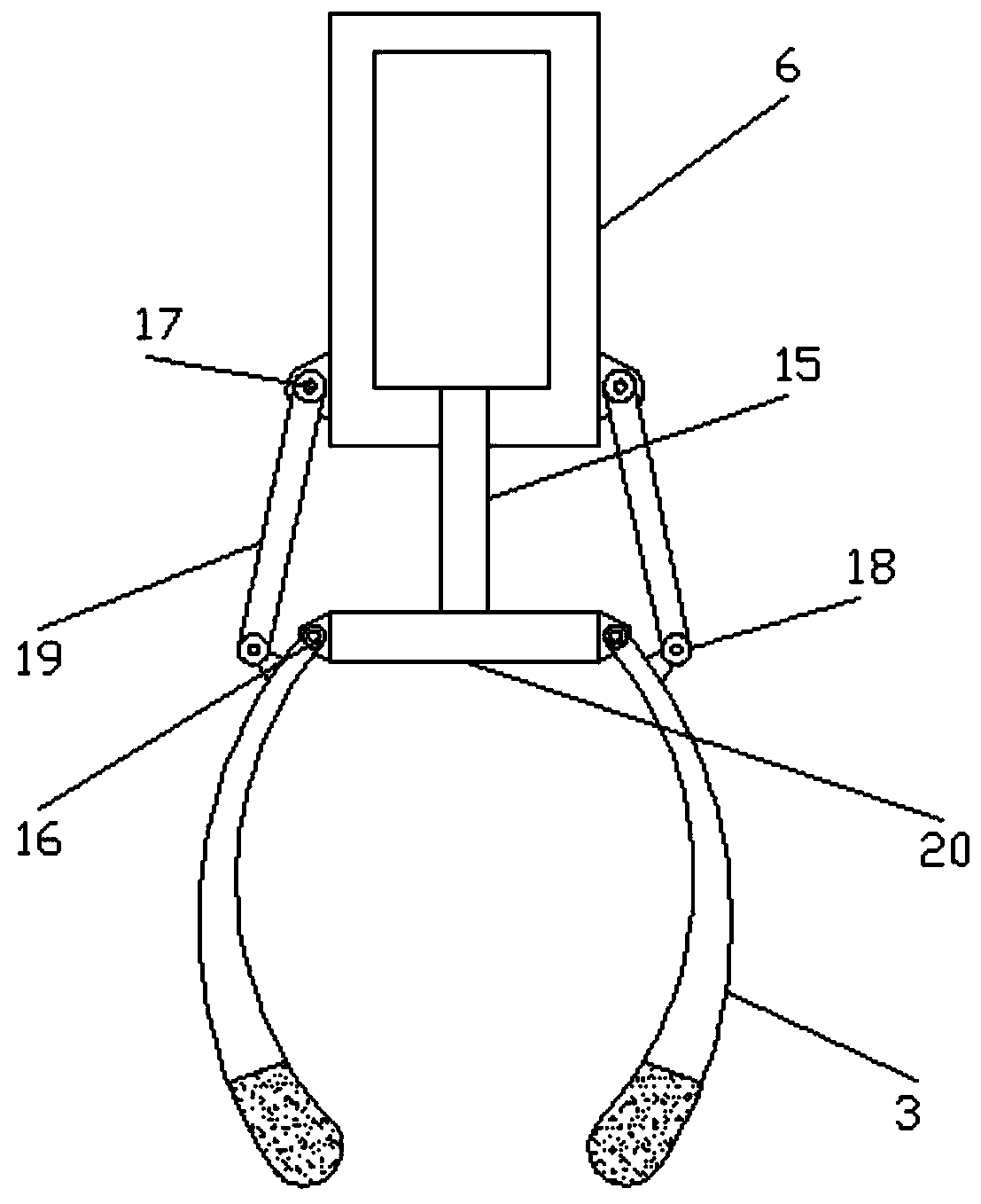

Tissue fixing device in laparoscopy

PendingCN110236701AAvoid coldEfficient and stable fixed placementInstruments for stereotaxic surgeryElectrical resistance and conductanceLaparoscopy

The invention discloses a tissue fixing device in laparoscopy. The tissue fixing device comprises a device body, a holding handle, a tissue fixing claw, fixing and supporting pressing plates, a lithium battery pack and a cylinder. The holding handle is connected with the top of the device body. The fixing and supporting pressing plates are arranged on the two sides of the middle of the device body. The tops of the fixing and supporting pressing plates are electrically connected with the lithium battery pack. The inner side end of each fixing and supporting pressing plate is electrically connected with an installing shaft. A heating resistance wire is electrically connected into each fixing and supporting pressing plate. A rubber cushion is attached to the bottom of each fixing and supporting pressing plate. NTC temperature sensors are distributed at the inner side bottom of each fixing and supporting pressing plate. A connecting shaft is arranged in the middle of the device body. The outer end of the supporting rod is connected with the tissue fixing claw through a first rotating shaft gear. The tissue fixing device in laparoscopy has the function of grabbing, fixing or blocking a certain part of tissue, has the main function of fixing in-vivo tissue organs, and is beneficial for exposing the view in the operation process and reducing accidental injuries.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

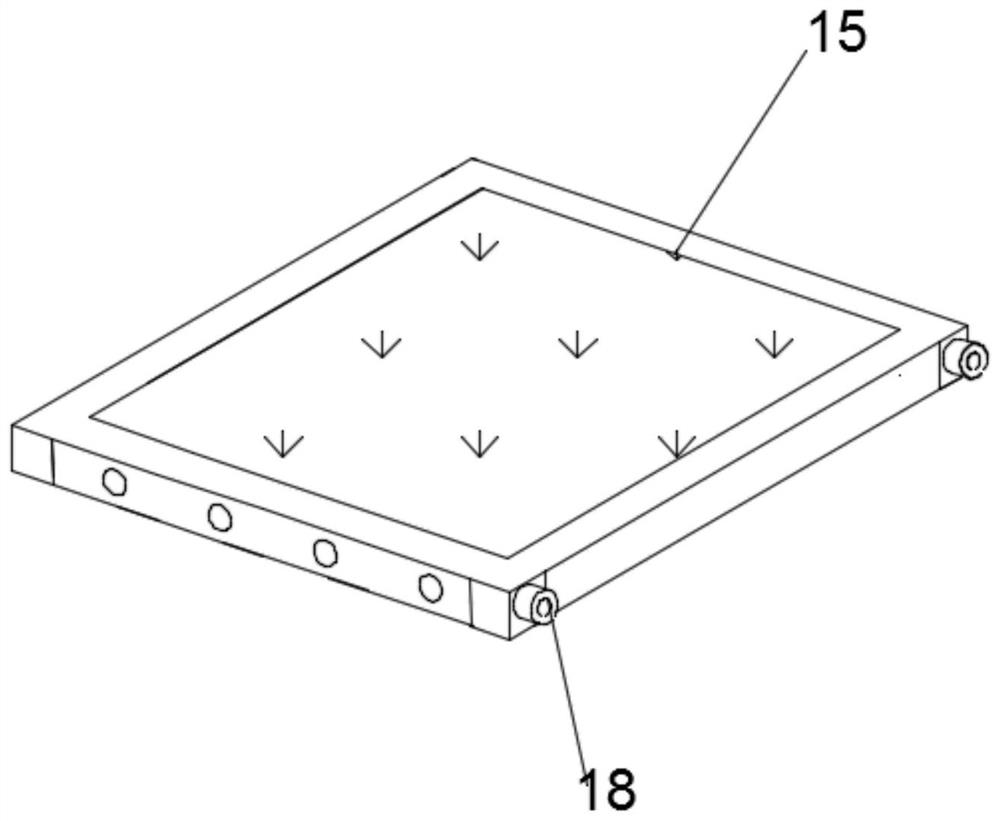

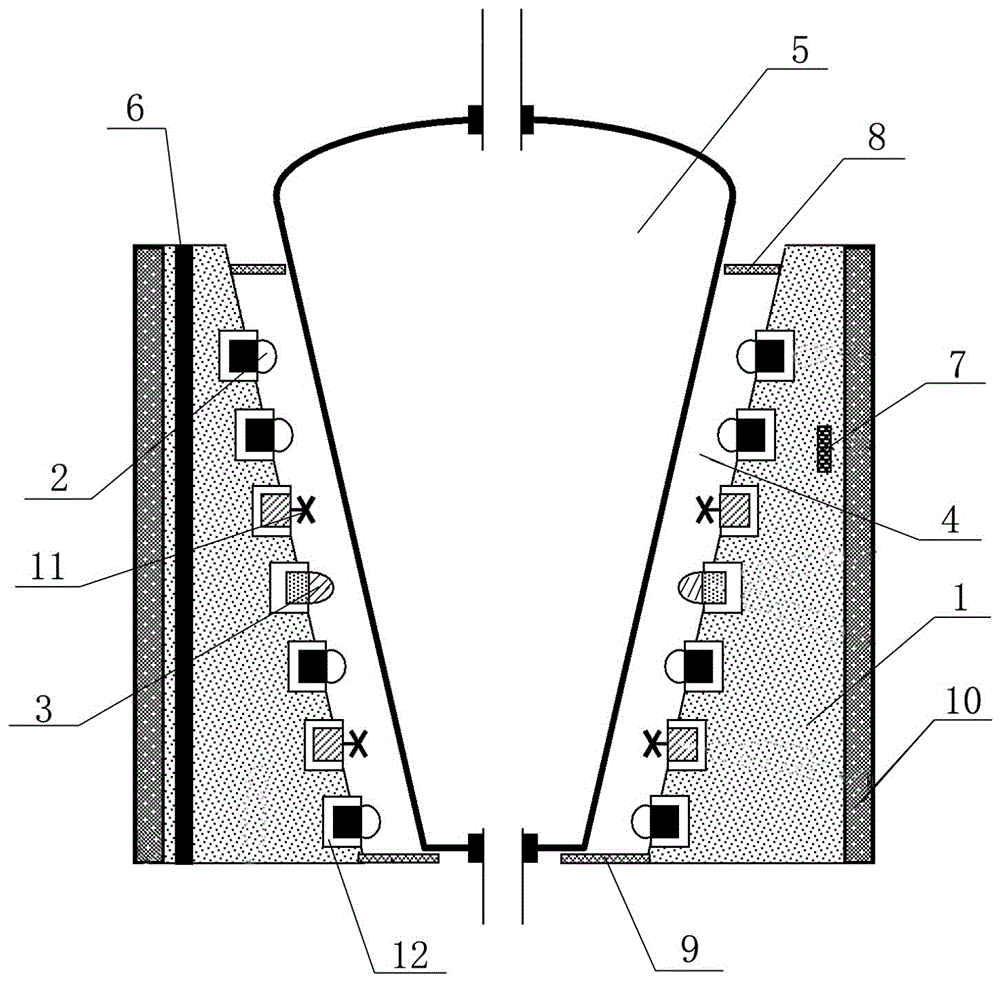

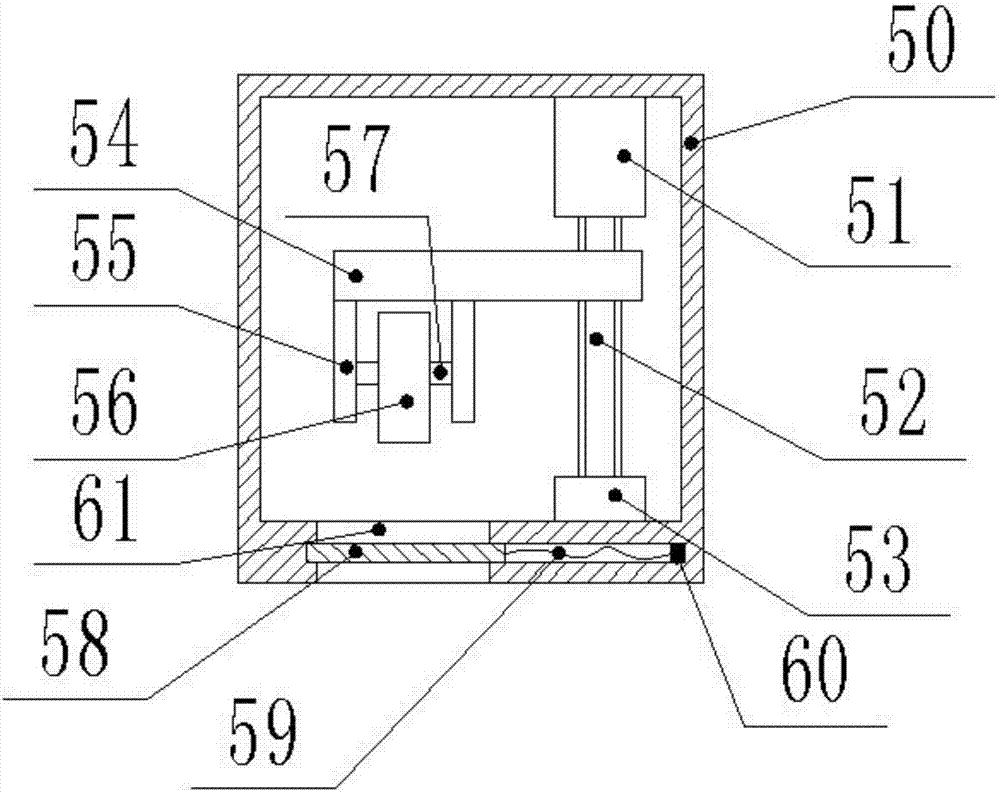

Infusion tube heating device with automatic temperature control function

ActiveCN106422004AHeating evenlyReal-time temperature monitoringInfusion devicesMedical devicesTemperature controlEngineering

The invention discloses an infusion tube heating device with an automatic temperature control function. The infusion tube heating device with the automatic temperature control function comprises a casing, heating lamp beads uniformly distributed on the inner wall of the casing, temperature sensors arranged on the inner wall of the casing, and a temperature control circuit; a hollow part is encircled by the inner wall of the casing and is used for accommodating a Murphy's dropper or an infusion hose; the hollow part penetrates through the upper surface and the lower surface of the casing. The infusion tube heating device with the automatic temperature control function is simple in structure, convenient to use and relatively good in heating effect; the infusion tube heating device with the automatic temperature control function can effectively control the temperature of medicinal liquid to be adapted to the temperature of a human body, and is conducive to fast absorption of the medicinal liquid, so that a patient feels comfortable.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

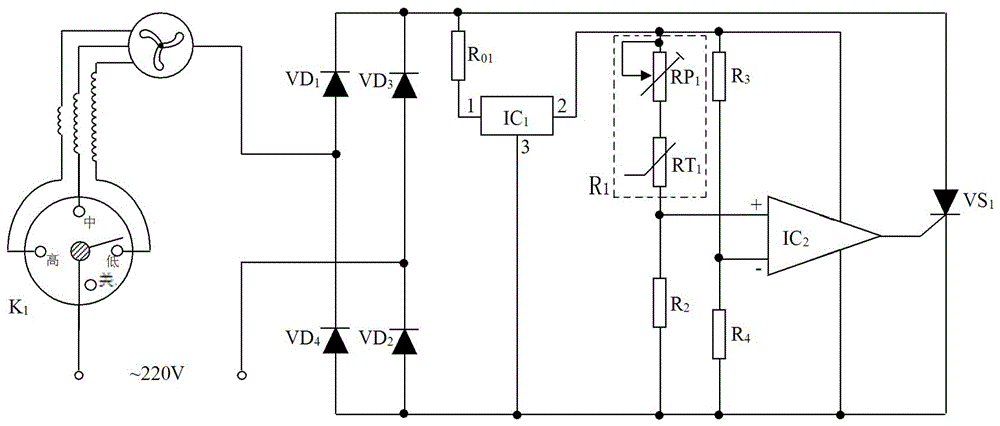

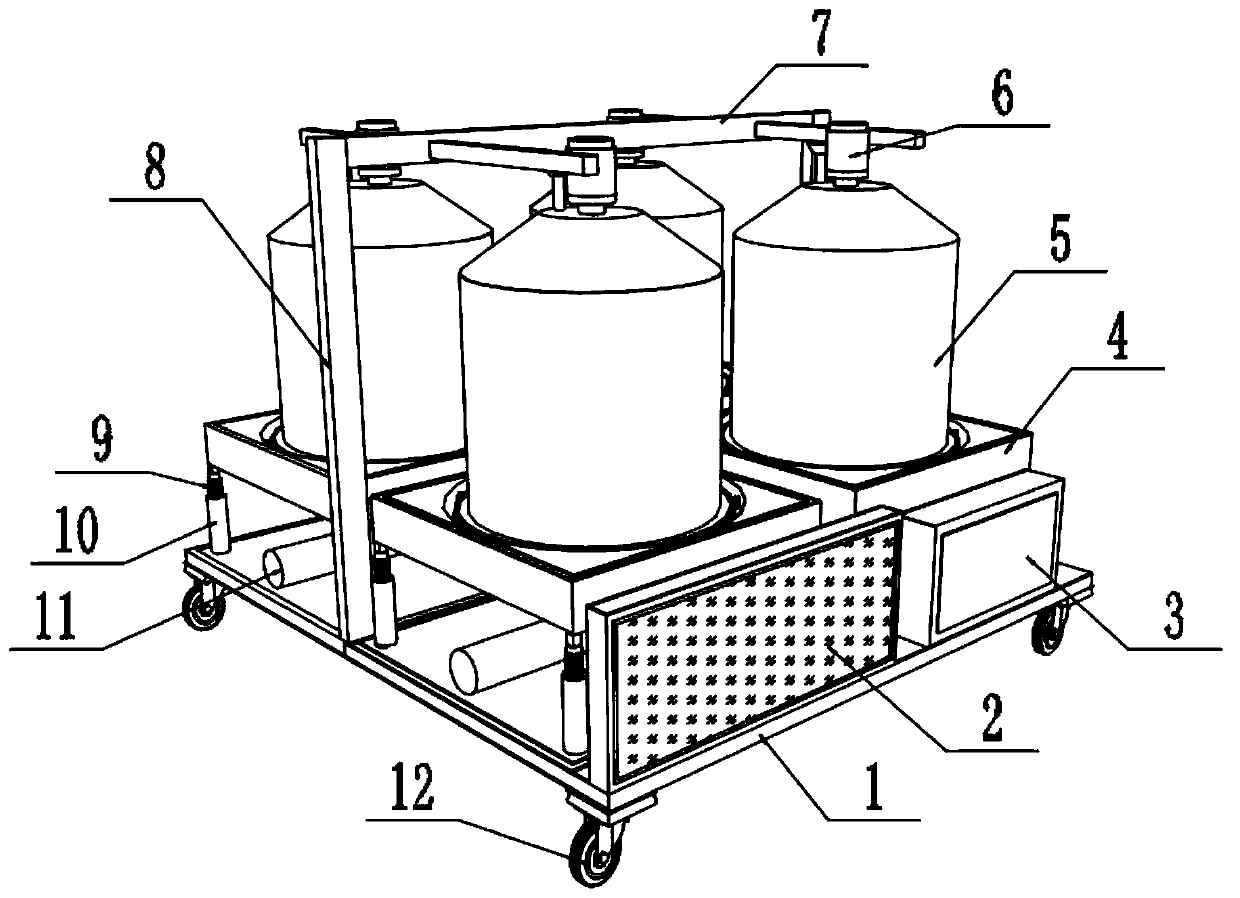

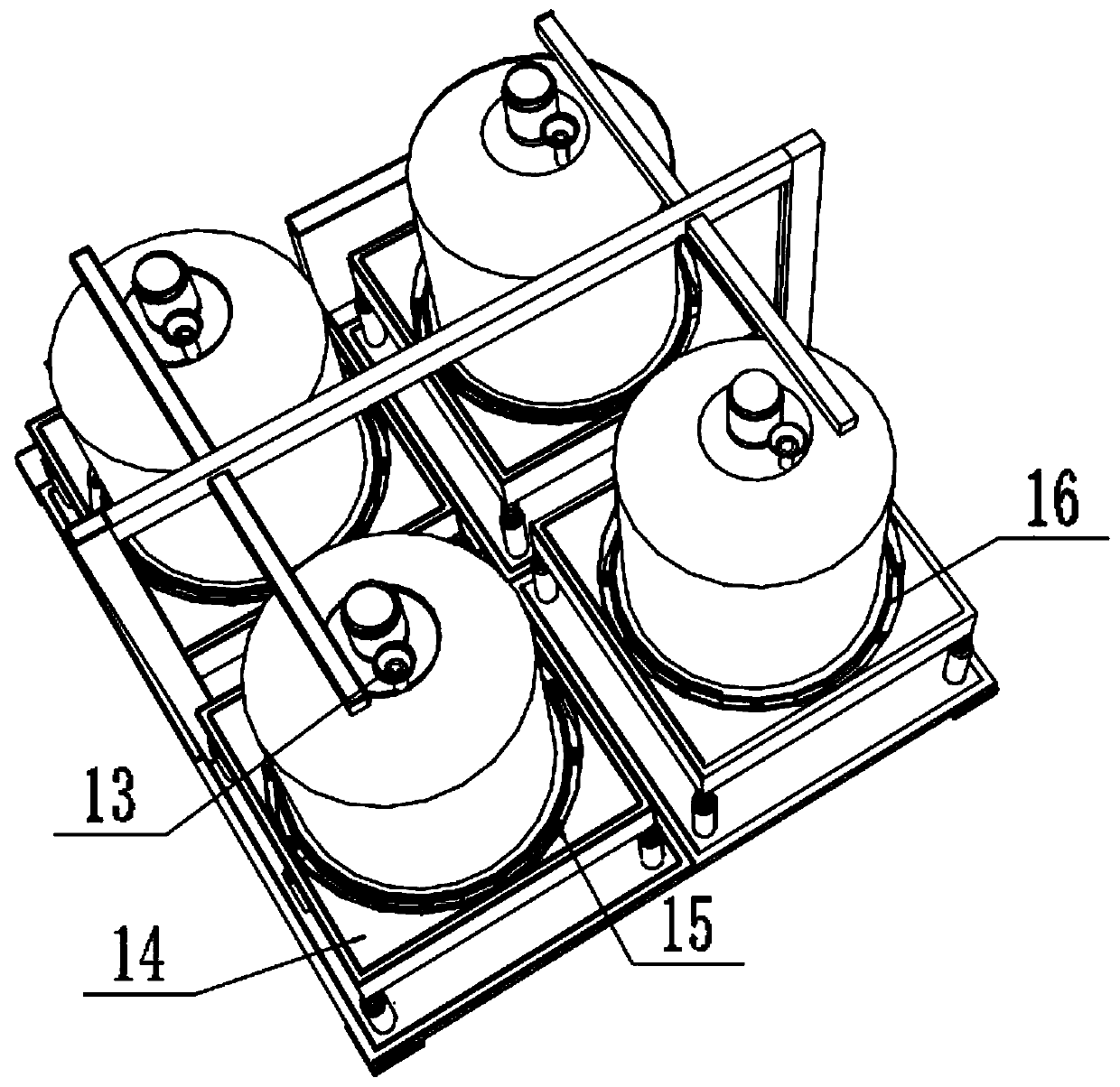

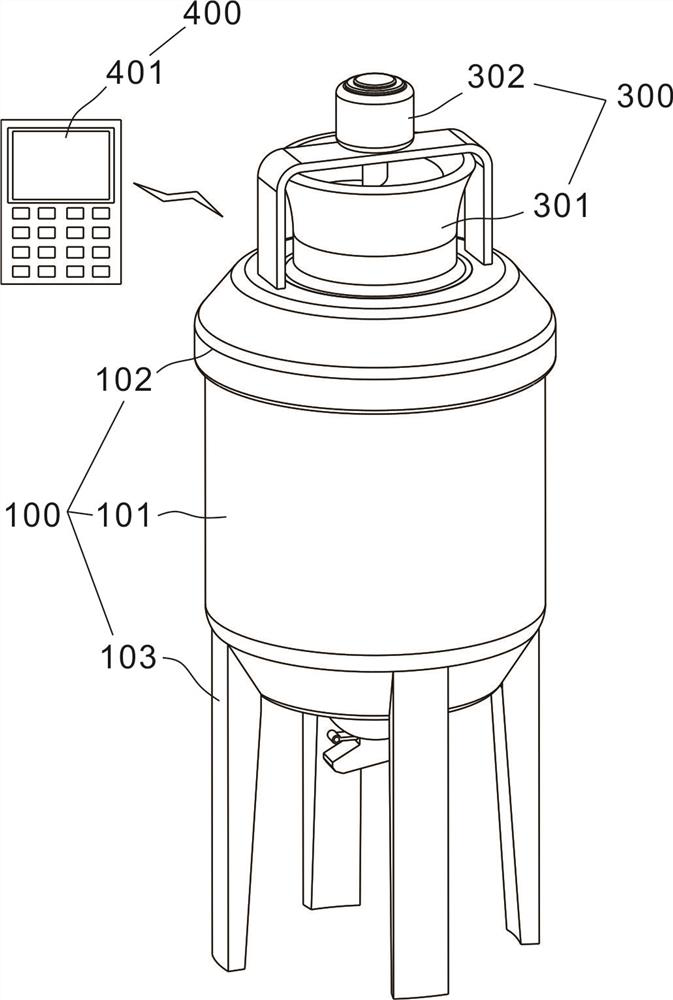

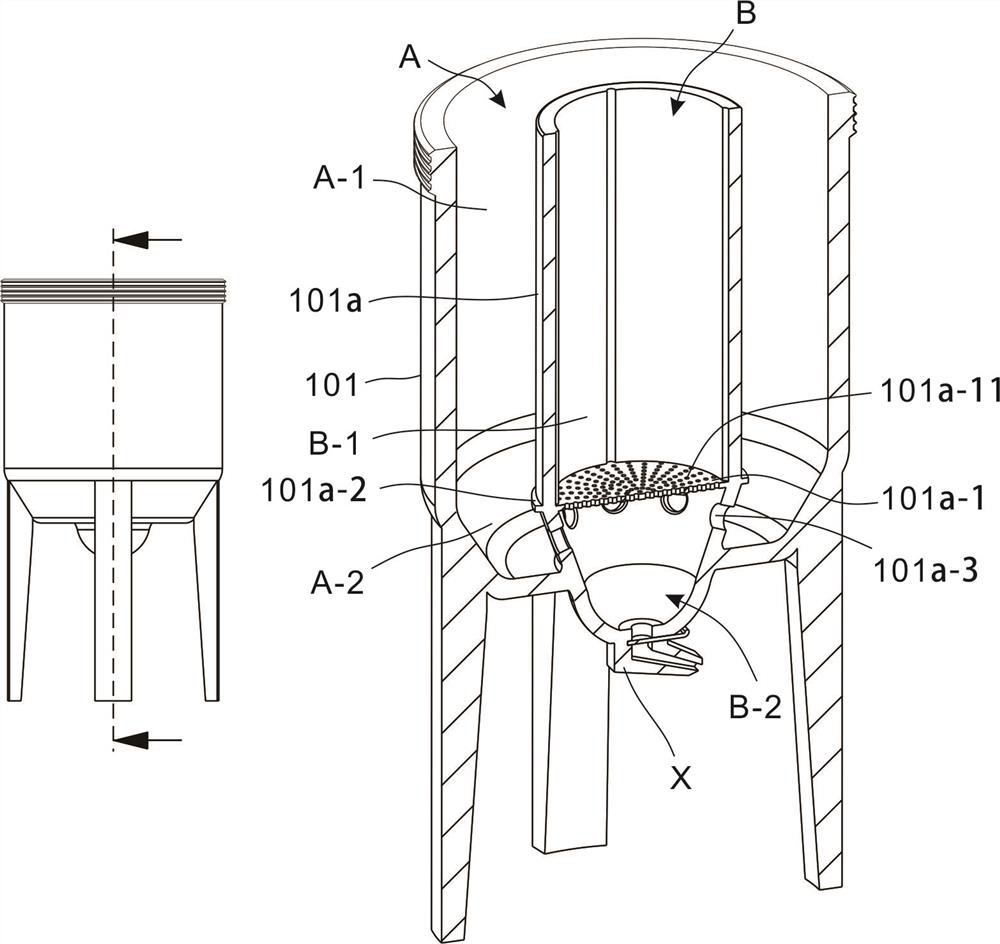

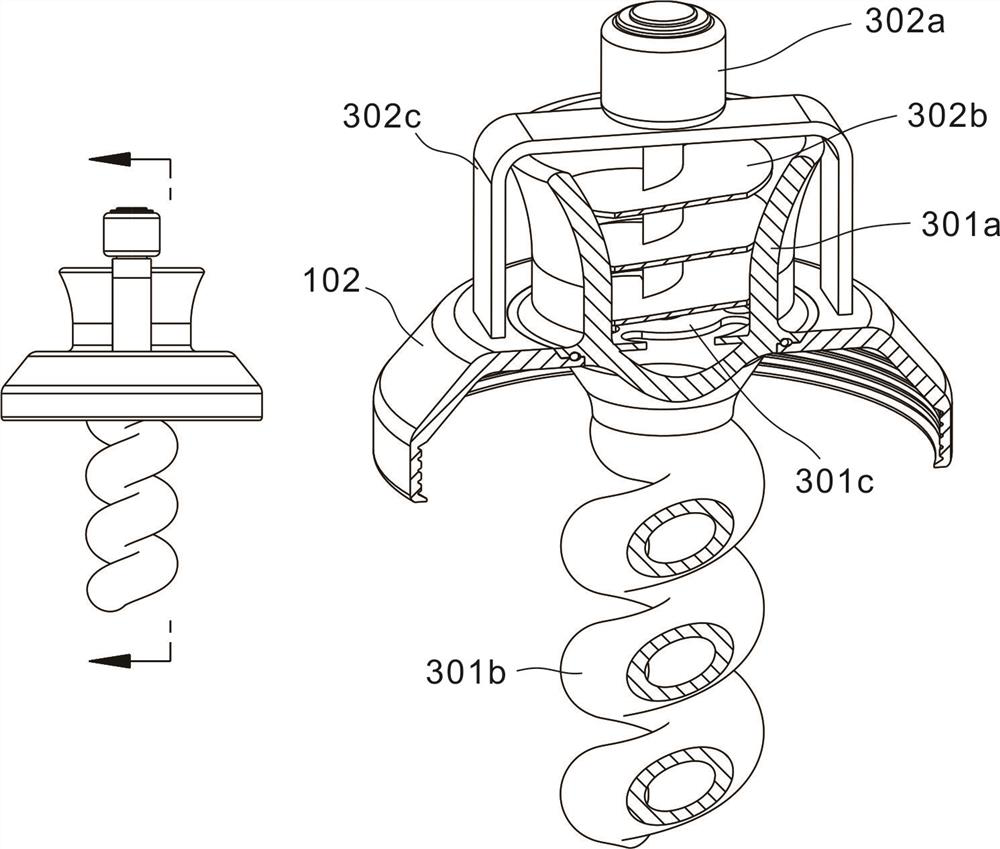

Spray glue raw material storage tank, storage equipment and storage system

InactiveCN110884781AKeep shakingGuaranteed uniformityLarge containersTank wagonsElectric machineControl cell

The invention discloses a spray glue raw material storage tank, storage equipment and a storage system. The storage system comprises a storage unit, a protection unit, a detection unit, a heating unitand a control unit. The storage unit comprises tank bodies, the heating unit comprises heating pipes, and the heating pipes are welded to the inner walls of the tank bodies. A first motor is fixed tothe top end of each tank body through a motor seat, a stirring rack is connected to an output shaft of the corresponding first motor through a coupler and fixed in each tank body through a bearing, the top end and the bottom end of each tank body are of circular truncated cone structures, and a feeding hopper is welded to the top end of each tank body. A feeding valve is connected to the outer wall of each feeding hopper in a clamped mode, and a discharging pipe is welded to the bottom end of each tank body. The equipment is convenient to move as a bottom plate and universal wheels are arranged; the stirring racks, the motors and the heating pipes are arranged in the storage tanks, and thus efficient heating can be achieved; and meanwhile, shaking of the raw materials in the tanks is maintained in the mode that the stirring racks are driven to rotate through the motors, and heating evenness of the raw materials is guaranteed.

Owner:GUANGDONG ORIENT RESIN

Multifunctional bed with combination socket

InactiveCN106889810ARealize the charging functionRealize the heating functionBedsBedstandsEngineeringMultiple function

The invention discloses a multifunctional bed with a combination socket. The multifunctional bed comprises a bed body and a bedside, wherein multiple drawers are arranged on the side surface of the bed body; a tabletop is arranged on the bedside; a processor is arranged in the tabletop; a control panel is arranged on the tabletop; a display screen, jacks and a plurality of keys are arranged on the control panel; a mattress is arranged on the bed body; a heating plate and a temperature sensor are arranged in the mattress; the processor is connected with the heating plate, the temperature sensor, the display screen and the keys; and bases are fixedly mounted at the four corners at the bottom of the bed body. The multifunctional bed is high in functionality and convenient to use, and can meet the increasing demands of people.

Owner:湖南海裕信息科技有限公司

Multifunctional leisure sofa

InactiveCN106820732ARealize the charging functionRealize the heating functionSofasCouchesEngineeringCushion

The invention discloses a multifunctional leisure sofa, comprising a sofa base; a cushion and a backrest are arranged on the soft base, and a processor and a control panel are arranged on the sofa base; the control panel comprises a display screen, a plug hole and several buttons; a heating piece and a temperature sensor are arranged in the cushion and the backrest; the processor is connected with the heating piece, the temperature sensor, the display screen and the button; four corners of the bottom part of the sofa base are fixedly equipped with bases. The multifunctional leisure sofa is strong in functionality, convenient to use, and can meet the demand of increasing growth of people.

Owner:湖南海裕信息科技有限公司

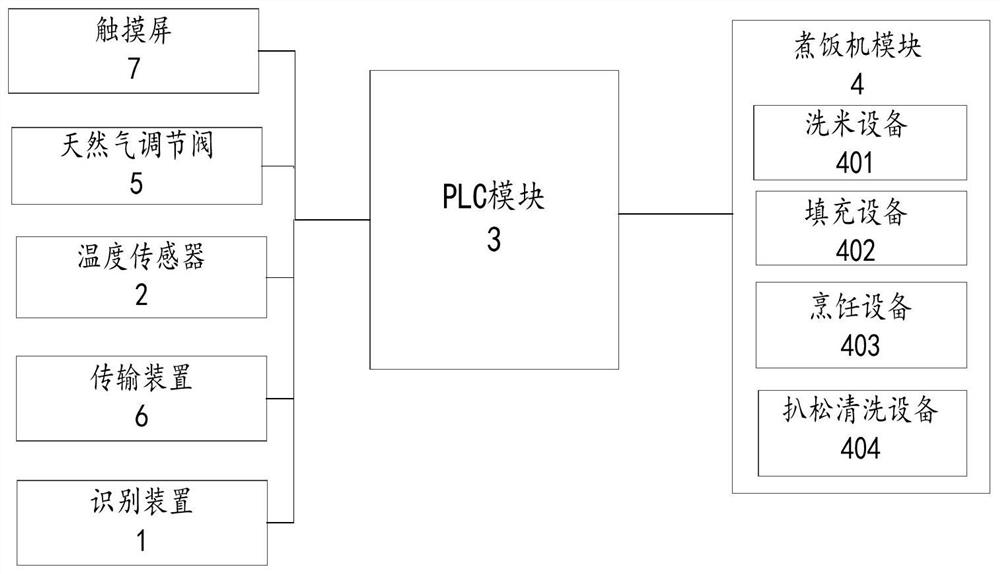

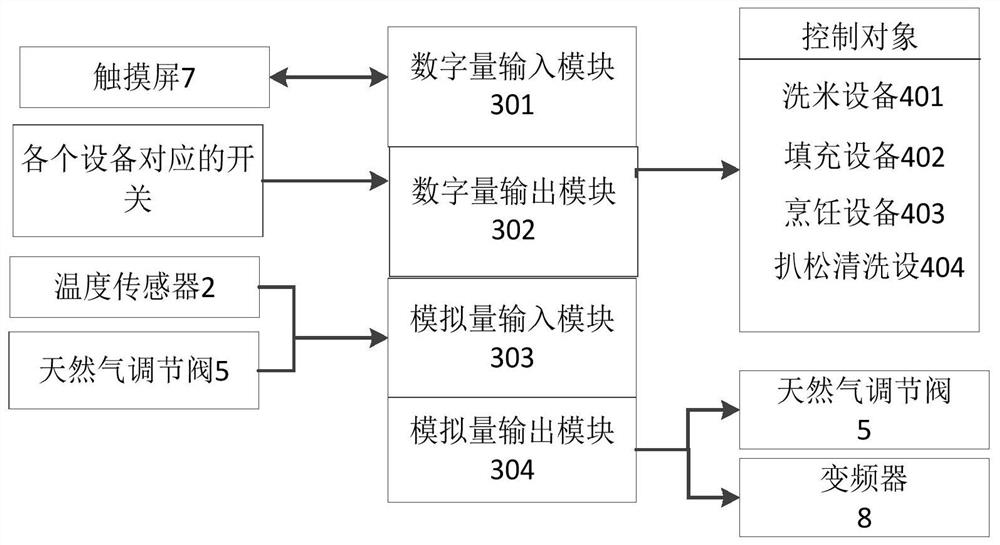

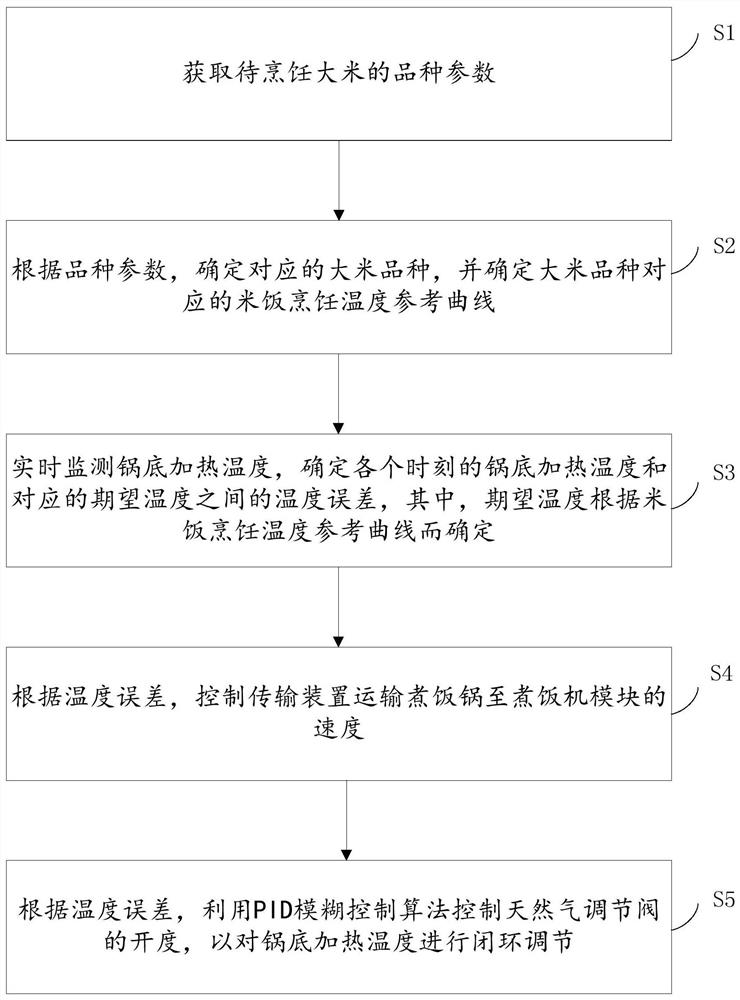

A control system and method for an industrial rice cooker

ActiveCN112890570BGuaranteed flexibilityGuaranteed intelligenceTemperatue controlCooking vesselsLoop controlRice dishes

Owner:HUAZHONG AGRI UNIV

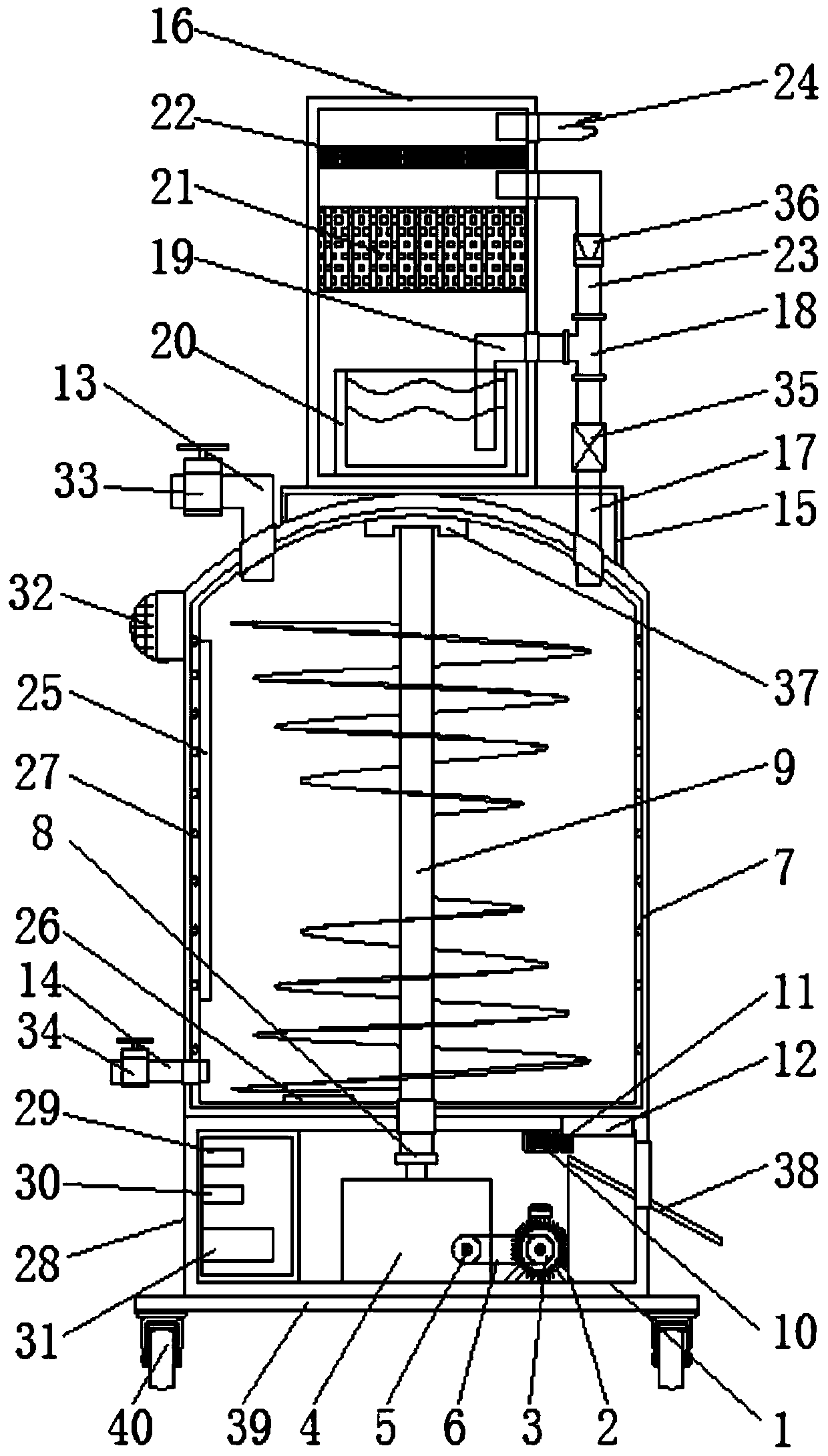

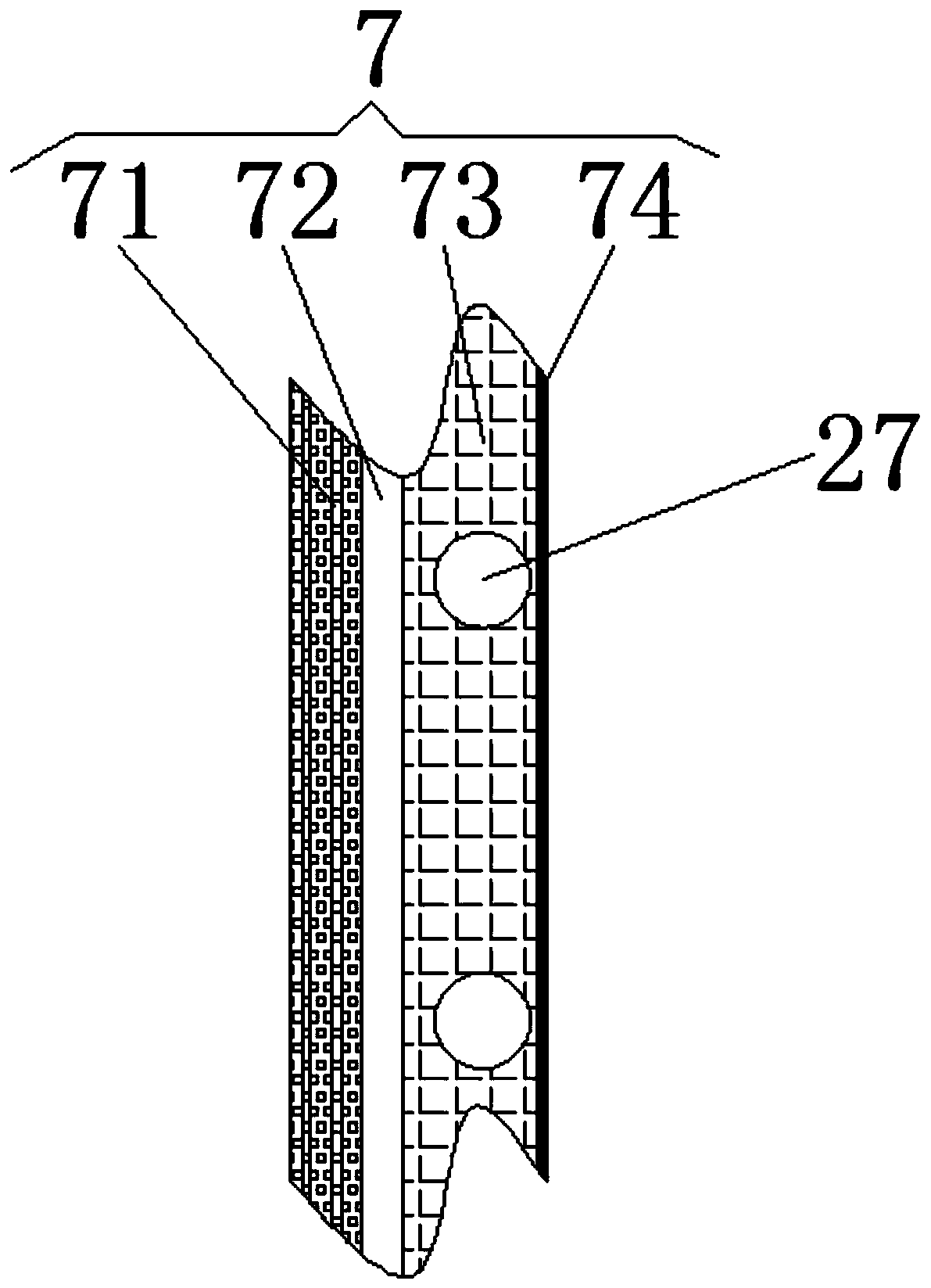

A multifunctional chemical production reactor

ActiveCN107597047BStir wellIncrease productivityDispersed particle filtrationChemical/physical/physico-chemical stationary reactorsSlagReducer

The invention discloses a multifunctional reaction kettle for chemical production. The multifunctional reaction kettle comprises a bottom box, wherein one side of the bottom of the inner wall of the bottom box is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a stirring device through a speed reducer; the top of the inner wall of the bottom box is fixedly connected with a second motor; an output shaft end of the second motor is fixedly connected with a gear; the surface of the gear is meshed with a slag removal device; one side of the top ofthe kettle body is communicated with a feed pipe; the top of the kettle body is fixedly connected with a gas treatment box through a support frame; one side of the inner wall of the kettle body is fixedly connected with a liquid level sensor; the bottom of the inner wall of the kettle body is fixedly connected with a temperature sensor; a heating pipe is fixedly connected in the wall body of the kettle body. The invention relates to the field of chemical technology. The multifunctional reaction kettle for chemical production solves the problems of waste gas treatment, is harmless to environment and humankind, has high automation degree and ensures stable product quality.

Owner:常州新东化工发展有限公司

An environmentally friendly and high-efficiency quartz stone calciner

ActiveCN113566578BEasy to maintain laterImprove the heating effectCharge manipulationCharge treatment typeHeater RodControl cell

The invention discloses an environment-friendly and high-efficiency quartz stone calcining furnace. The calcining furnace includes a furnace body, a heating unit and a control unit. The furnace body includes a furnace body, and is matched with a furnace cover arranged on the side wall of the top of the furnace body, and The supporting feet are arranged on the outer side wall of the lower end of the furnace body; the heating unit is arranged in the inner cavity of the furnace body, which includes a heat conduction cylinder and a heating rod arranged in the heat conduction cylinder; and a control unit, which is electrically connected to the heating rod, It includes a control box located outside the furnace body and a monitoring component located in the furnace body, and the control box is electrically connected to the monitoring component; the furnace body in the present invention is a novel combined structure, which effectively distinguishes the inner cavity of the furnace body, It is convenient for the later maintenance of the furnace body, and at the same time, the more reasonably distributed heating units greatly improve the heating effect of the furnace body and are easier to maintain; the monitoring component can monitor the heating temperature in the furnace in real time to improve the energy saving effect of the heating unit. The furnace cover structure is easy to keep warm and charge.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

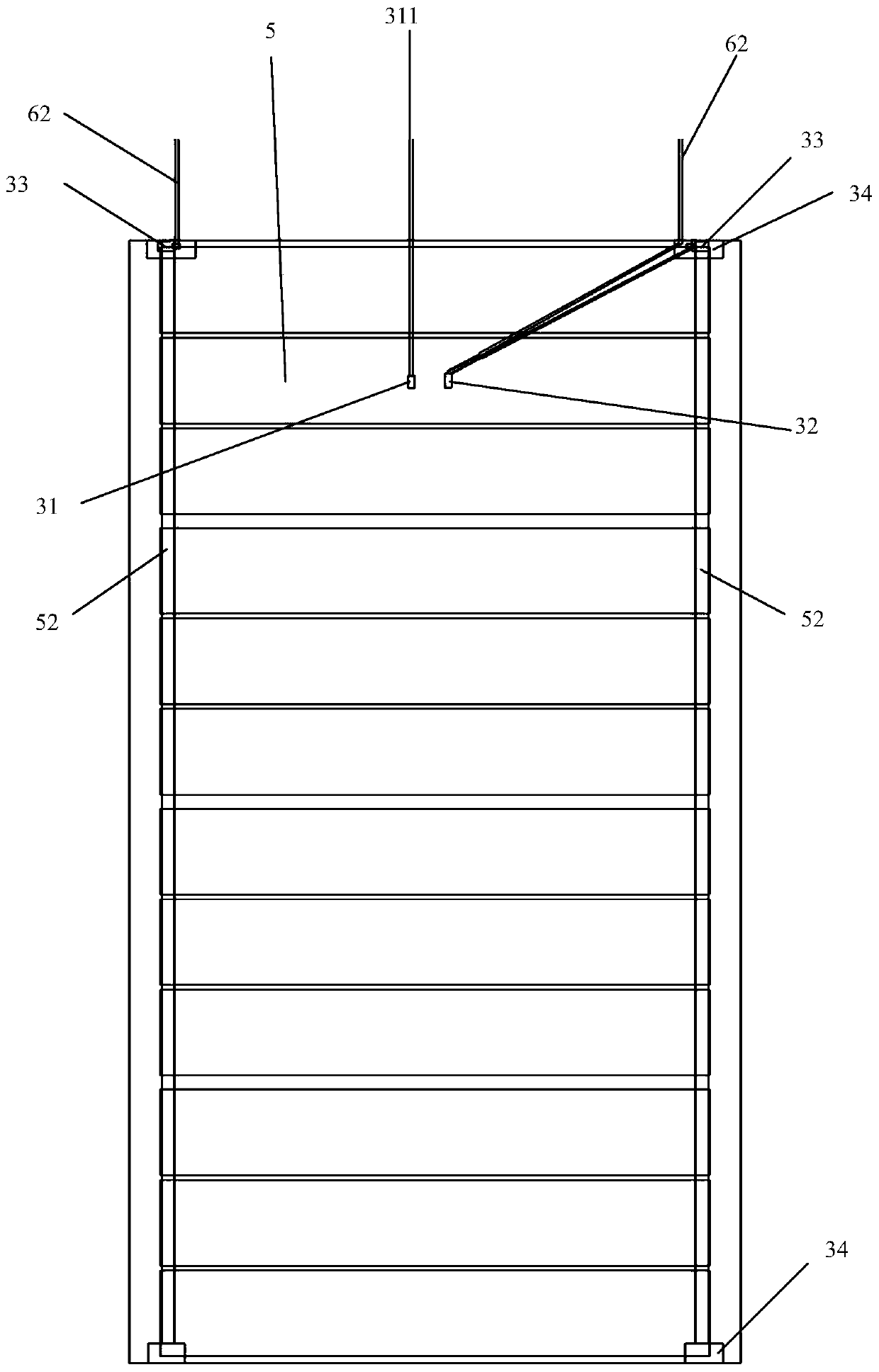

Graphene heating brick circuit structure

PendingCN111163537ATo ensure resistance errorReal-time monitoring of heating temperatureOhmic-resistance electrodesHeating element materialsComposite electrodeGraphite

The invention discloses a graphene heating brick circuit structure. The graphene heating brick circuit structure comprises a graphene heating brick and an intelligent temperature controller electrically connected with the graphene heating brick, a graphene heating film comprises a polymer film, a heating film current-carrying electrode, an electrode connector, a graphene heating layer, a compositeelectrode and a PET film which are sequentially arranged from top to bottom, and the heating film current-carrying electrode, the electrode connector and the composite electrode are arranged on the two sides of the graphene heating layer; the graphene heating chip layer is provided with a thermistor, the thermistor is fixedly connected with the graphene heating film, and the thermistor is electrically connected with the intelligent temperature controller through a thermistor signal line. According to the graphene heating brick circuit structure, the composite electrode is arranged, the resistance value of each graphene heating layer is checked through the composite electrode, it is ensured that the resistance value error of each graphene heating layer is within the standard range, the thermistor is arranged to monitor the heating temperature in real time, and safety and effective temperature control are ensured.

Owner:FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

Method for improving hardenability by spray cooling and processing equipment improving hardenability by spray cooling

PendingCN113736958ATake advantage ofIncrease motivationIncreasing energy efficiencyFurnace typesTemperingFree cooling

The invention discloses a method for improving hardenability by spray cooling and processing equipment improving hardenability by spray cooling, and belongs to the field of heat treatment of shaft products. The method mainly comprises the following steps that a workpiece to be machined is placed in a hearth of an electromagnetic induction heating furnace to be heated; the heated workpiece is fed into a cooling device to be gradually cooled in a cooling water spraying manner; after the workpiece is cooled to the required temperature, the workpiece is put into the hearth of the electromagnetic induction heating furnace again to be subjected to tempering heating; and the temperature of the tempered and heated workpiece is reduced to the normal temperature in a natural cooling or spray cooling manner. Tempering and quenching are carried out by adopting a single workpiece pass-type cooling manner, the phenomenon that a hardening layer is unstable due to concentrated water cooling of a product is avoided, and the hardenability of the product is improved from 10-11 mm to 15-16 mm by improving heat treatment equipment under the condition that the product does not have hardening and tempering cracks, so that the hardenability of the product is improved to the maximum extent. The method and the equipment are mainly used for workpiece quenching.

Owner:临沂业隆通用机械有限公司

Power regulation circuit for motor cooling equipment of stamping robot

ActiveCN108879612BIngenious ideaReal-time monitoring of heating temperatureEmergency protective circuit arrangementsControl signalComputer module

The present invention discloses a power regulation circuit for a motor radiating device of a stamping robot. The circuit comprises a temperature detection circuit, a voltage stabilization calibrationcircuit and a PWM signal conversion circuit. The temperature detection circuit detects a heating temperature of a servo motor in real time when a stamping rotor works through an HE-205 infrared temperature measurement probe J1, the voltage stabilization calibration circuit employs an operational amplifier AR1, an operational amplifier AR2 and a variable resistor RW1 and a variable resistor RW2 toform a composite circuit to perform signal voltage stabilization processing, the signals are finally subjected to in-phase amplification through the operational amplifier AR3 and then input into a PWMsignal conversion circuit, and the PWM signal conversion circuit employs an operational amplifier AR4, an operational amplifier AR5, a capacitor C3 and a capacitor C4 to form a composite conversion circuit to convert voltage signals to PWM signals. The power regulation circuit can monitor the heating temperature of the servo motor in real time when the stamping robot works and can output accuratePWM control signals according to the temperature to drive the radiating driving module of the servo motor of the stamping robot to work.

Owner:肇庆市维特利机械科技有限公司

Vitreous body self-heating shower room with multimedia interaction function

PendingCN111629465AImprove sexual functionEasy to open and closeComputer controlTransparent/reflecting heating arrangementsCarbon fibersEngineering

The invention provides a vitreous body self-heating shower room with a multimedia interaction function. The shower room comprises a heating glass side wall, the heating glass side wall is arranged tobe of a cuboid structure in a surrounding mode, the heating glass side wall is of a double-layer structure, a heating body is arranged in the heating glass side wall to make the heating temperature inthe shower room uniform, an electric control door is arranged on the front side of the cuboid structure, and touch switches are arranged on the inner side and the outer side of the electric control door to facilitate opening and closing of the electric control door. The shower room also comprises a multimedia interactive display screen and a loudspeaker. Audio and video programs can be played, entertainment and functionality of the shower room are improved. Carbon fiber light-emitting wires are also arranged in the side wall of the heating glass, and error collision is prevented. A temperature sensor is further arranged in the shower room, the temperature can be monitored in real time to ensure that the heating temperature is proper, the communication and remote control module is connected with a smart phone or other internet-of-things units in a family, the shower room can be preheated remotely in advance, a media library is connected with the shower room, all components are controlled through a control assembly, and the intelligent degree is high.

Owner:CHANGZHOU ADAM BIOTECH

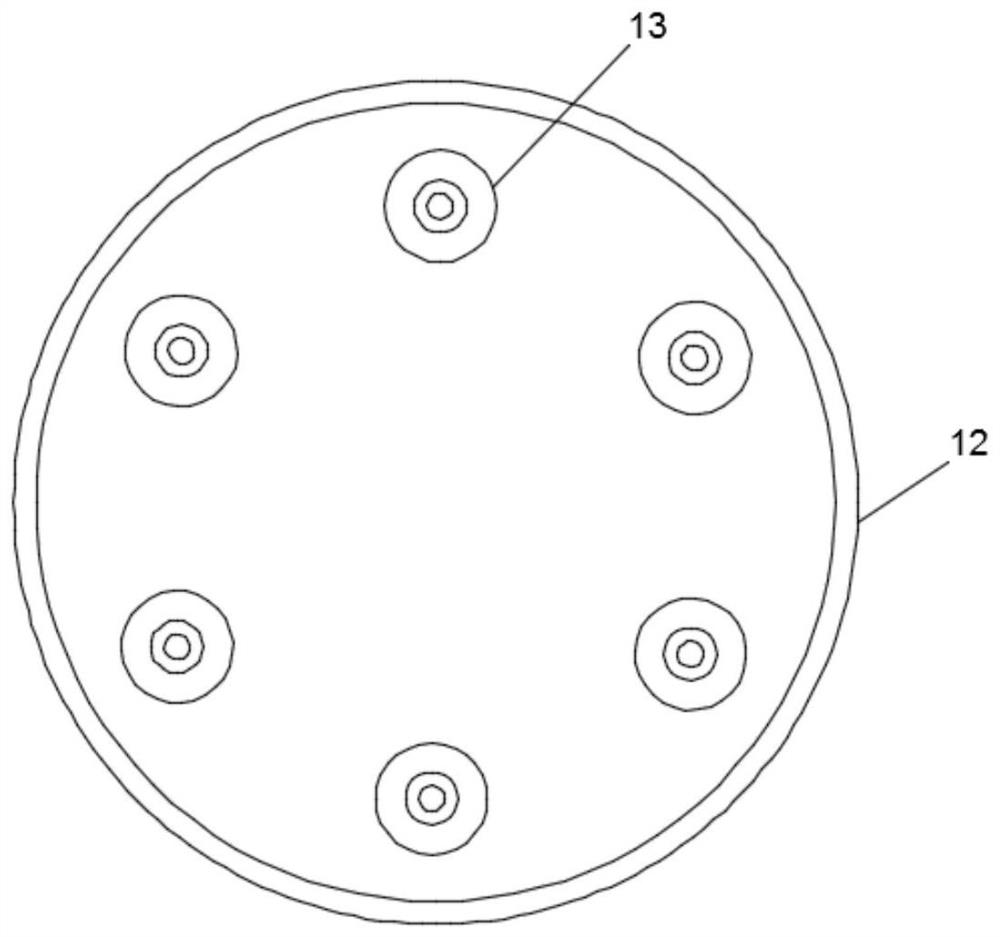

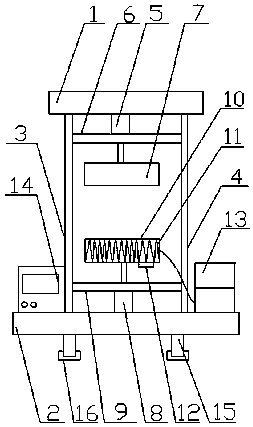

Plastic compression molding machine

The invention provides a plastic compression molding machine. The machine comprises a top frame and a base, wherein a first rack and a second rack are symmetrically arranged between the top frame andthe base; an upper compression die hydraulic cylinder is arranged at the upper end of the middle part of the top frame, and an upper pressing plate is connected to the lower part of the upper compression die hydraulic cylinder; an upper compression die is arranged at the lower part of an upper compression plate; a lower compression die hydraulic cylinder is arranged at the upper end of the middlepart of the base, and a lower compression plate is arranged on the lower compression die hydraulic cylinder; a lower compression die is connected to the upper part of the lower compression plate, anda high-frequency induction coil is arranged in the lower compression die; a temperature sensor is arranged at the bottom part of the lower compression die; a high-frequency power supply is arranged atthe right side of the second rack; a PLC control end is arranged at the left side of the first rack; supporting feet are arranged below the base; the high-frequency induction coil is connected to thehigh-frequency power supply through a conductor; and the upper compression die hydraulic cylinder, the lower compression die hydraulic cylinder, the high-frequency power supply and the temperature sensor are electrically controlled to the PLC control end. According to the machine, the rubber plastic heating time can be accurately controlled, and excessive or insufficient heating time can be avoided, so that the defective percentage can be effectively reduced.

Owner:芜湖凯兴汽车电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com