Method for improving hardenability by spray cooling and processing equipment improving hardenability by spray cooling

A processing equipment and hardenability technology, applied in the field of methods and processing equipment, can solve the problems of high cost of quenching agent, difficult process control, unstable product quality, etc. The effect of layer maximization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

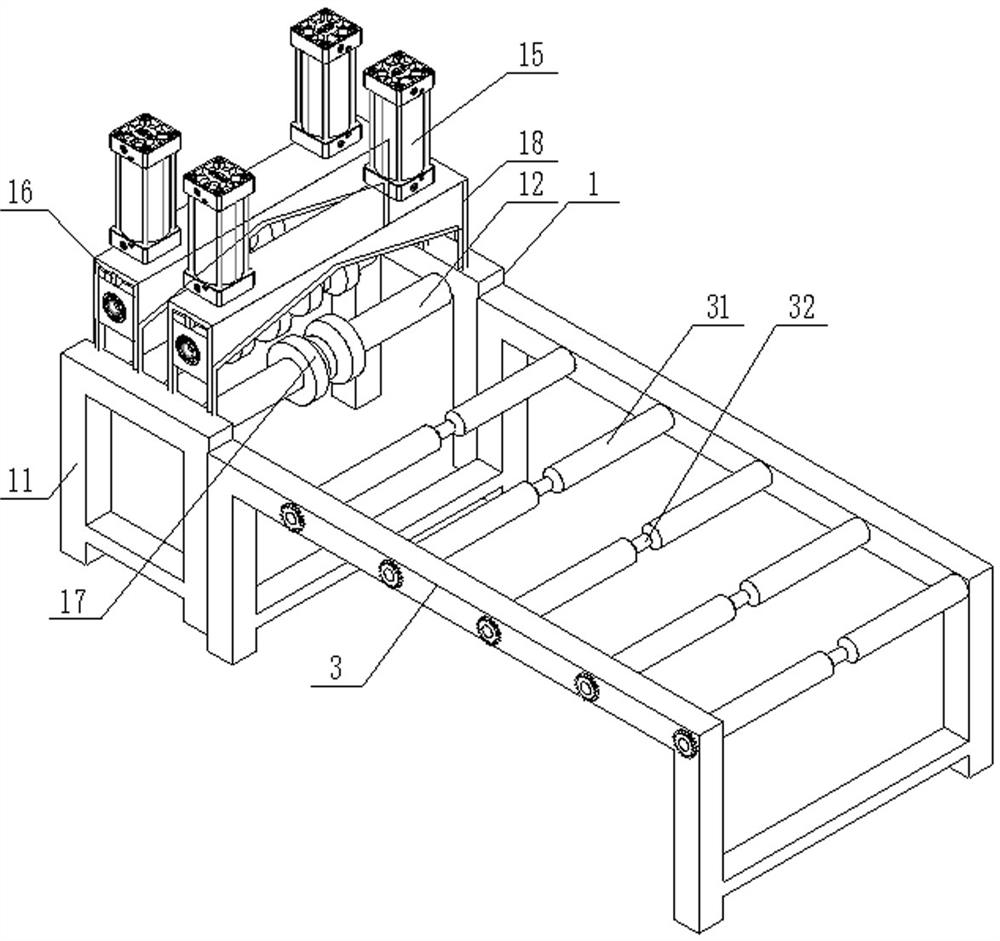

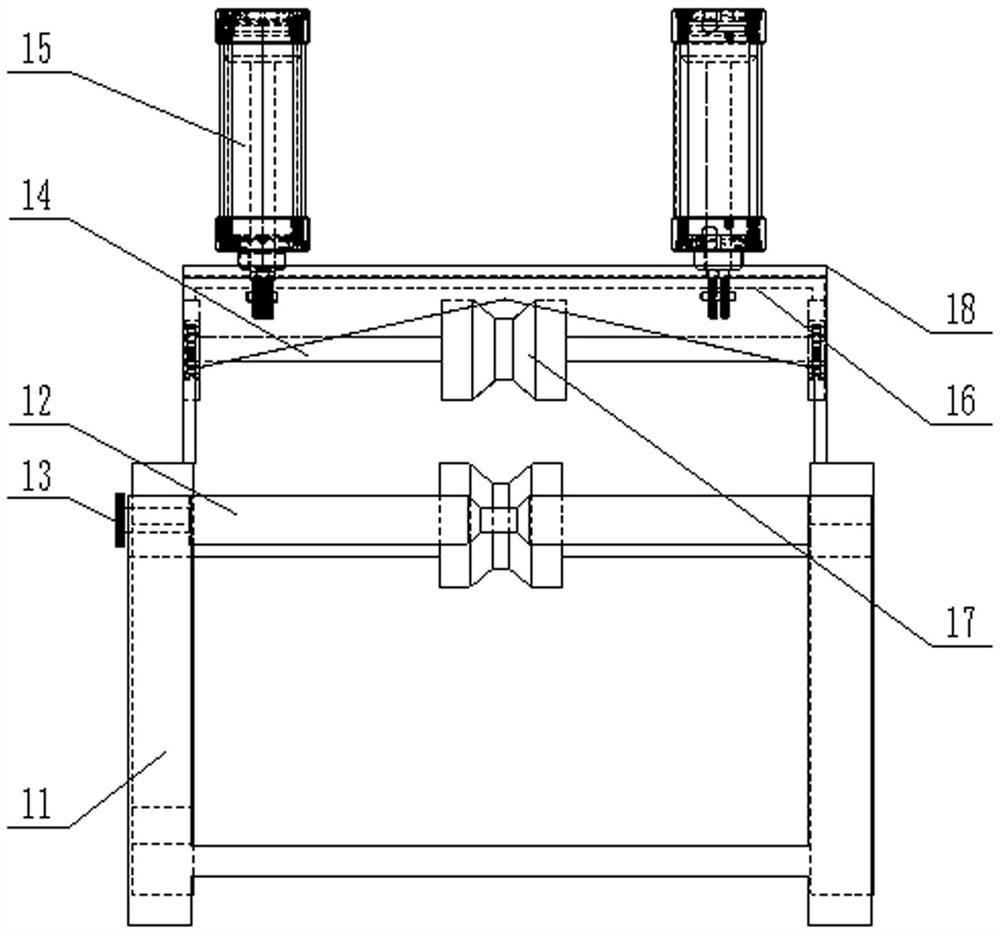

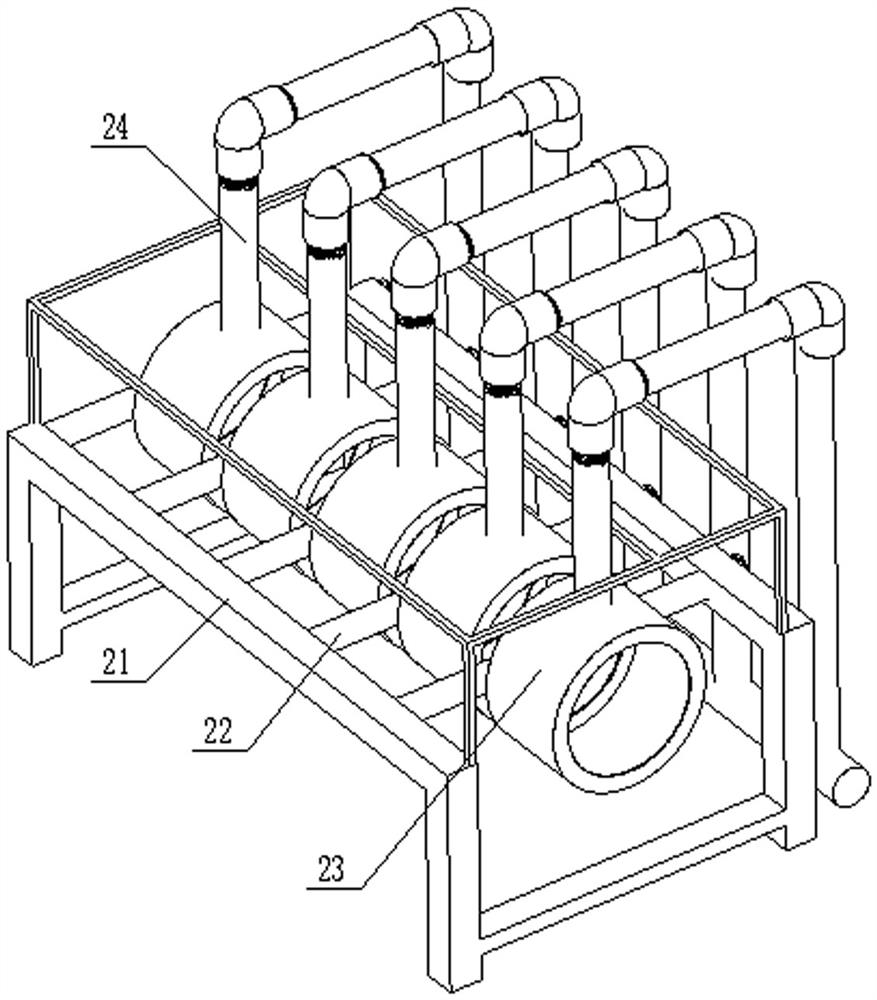

[0030] Embodiment 1: The processing equipment that utilizes spray cooling to improve hardenability includes a feeding device 1, an electromagnetic induction heating furnace and a cooling device 2. The feeding device 1 includes a workpiece clamping mechanism and a transmission device 3, and the transmission device 3 and the electromagnetic induction The furnace inlet of the heating furnace is connected, and the furnace outlet is connected with the cooling device 2 .

[0031] Such as figure 1 and figure 2 As shown, the workpiece clamping mechanism includes a frame 11, the frame 11 is fixedly connected with the transmission device 3, the transmission device 3 is provided with a plurality of transmission shafts 31, the transmission shaft 31 is provided with a limit groove 32, and the transmission shafts 31 are respectively installed Sprocket, adjacent two sprockets are connected by chains, frame 11 is provided with a support frame 18 that is fixedly connected, and support frame ...

Embodiment 2

[0041] Embodiment 2: The workpiece to be processed is 100mm in diameter, the material is 40Cr, the quenching heating temperature in step 1 is 780-800°C, the DC voltage of the electromagnetic induction heating furnace is 380V, and the intermediate frequency voltage is 520V; the tempering heating temperature is 610-620°C ℃, the DC voltage of the electromagnetic induction heating furnace is 340V, and the intermediate frequency voltage is 510V; after tempering, the temperature of the workpiece is reduced to normal temperature through natural cooling; the others are the same as in Embodiment 1. The workpiece hardness can reach 250-280HB.

Embodiment 3

[0042] Embodiment three: the workpiece to be processed is 110mm in diameter, the material is 42CrMo, the quenching heating temperature in step 1 is 750-770°C, the DC voltage of the electromagnetic induction heating furnace is 350V, and the intermediate frequency voltage is 480V; the tempering heating temperature is 650-660°C ℃, the DC voltage of the electromagnetic induction heating furnace is 340V, and the intermediate frequency voltage is 490V; the others are the same as in Embodiment 1. The workpiece hardness can reach 230-285HB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com