An environmentally friendly and high-efficiency quartz stone calciner

A high-efficiency, quartz stone technology, used in furnaces, charge materials, electric furnace heating, etc., can solve the problems of easy burning and maintenance of resistance wires, heat loss, inconvenience, etc. The effect of post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

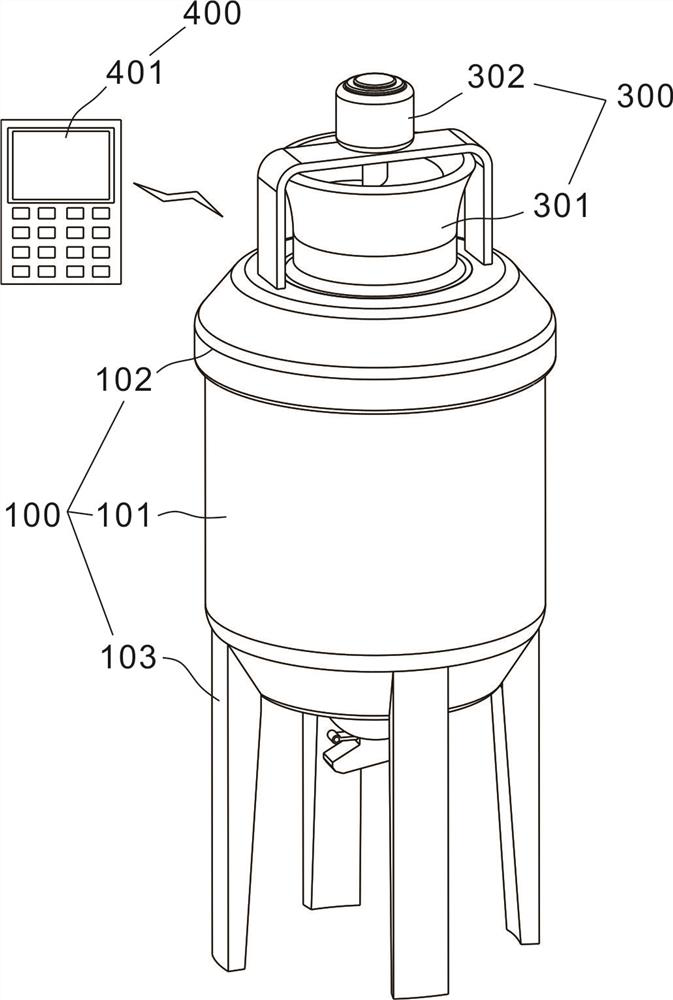

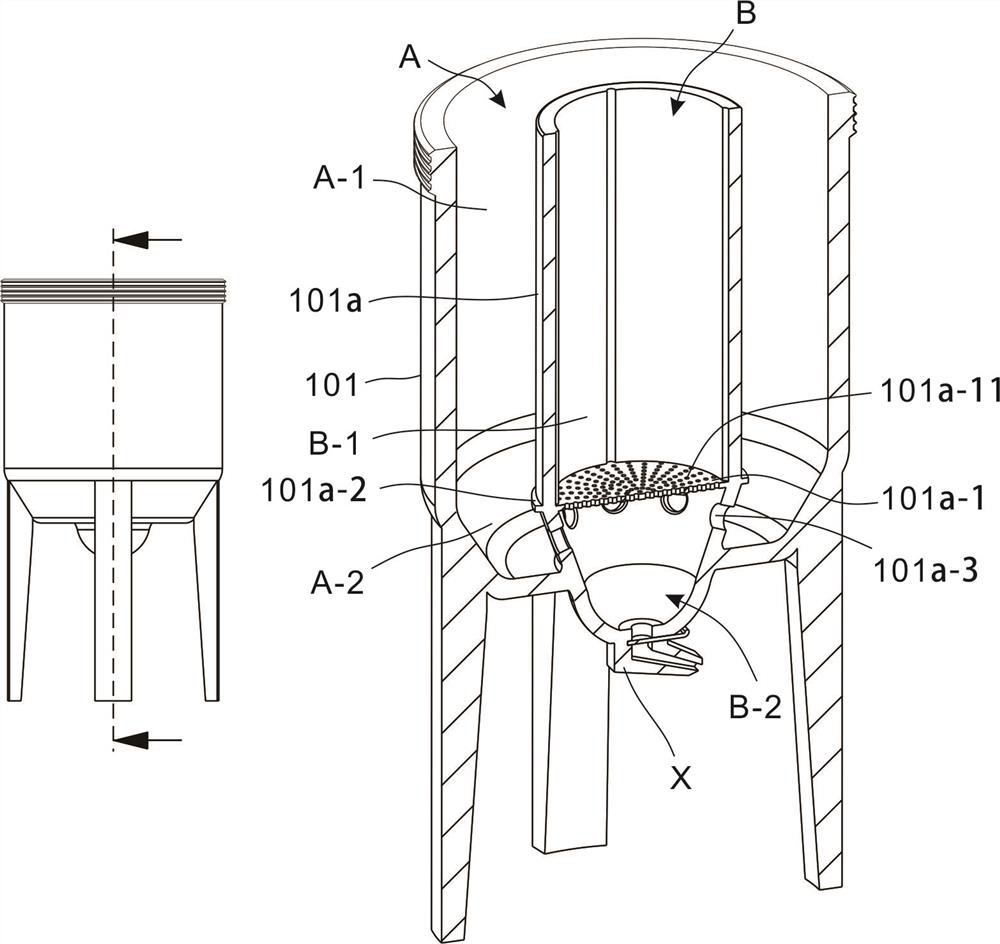

[0035] refer to Figure 1~Figure 7 , which is the first embodiment of the present invention, provides an environmentally friendly high-efficiency quartz calciner. The main structure of the calciner includes a furnace body 100, a heating unit 200 located inside the furnace body 100 and a charging unit located in the furnace body 100. 300.

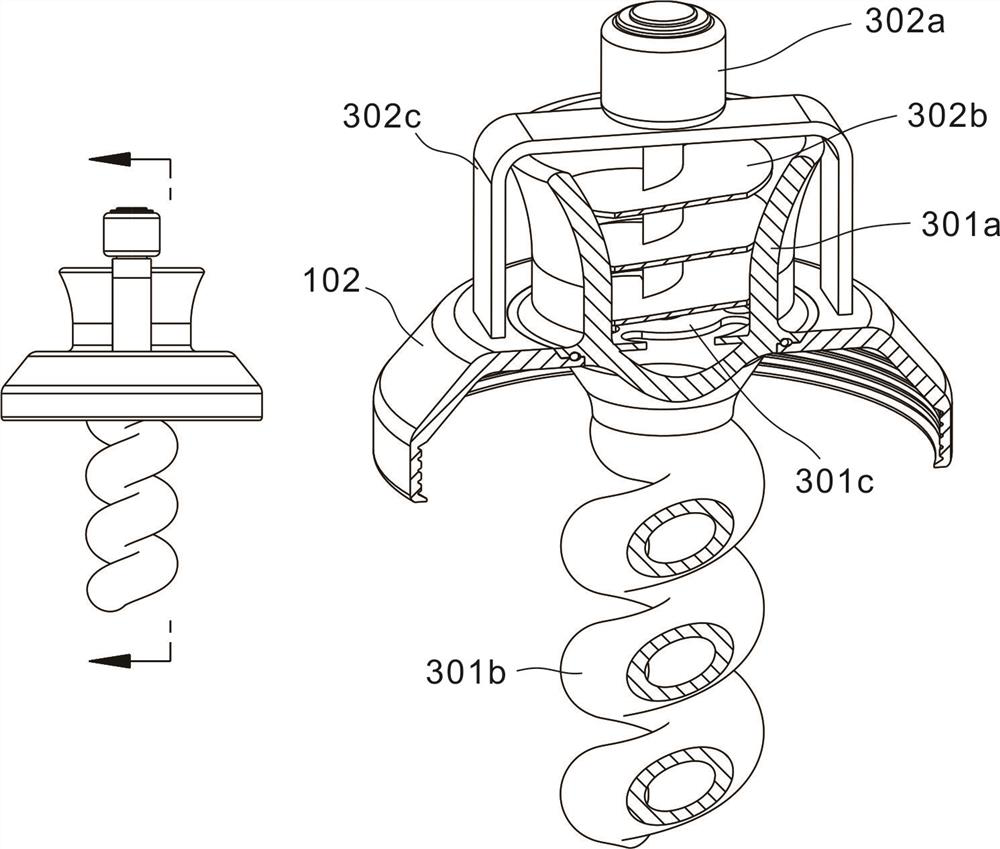

[0036] Specifically, combined with figure 1 with figure 2 , the furnace body 100 includes a furnace body 101 and a furnace cover 102, the furnace cover 102 is cooperatingly arranged on the top side wall of the furnace body 101, and a support foot 103 is also provided on the outer side wall of the lower end of the furnace body 101; the heating unit 200 is configured in In the inner cavity of the furnace body 101, it includes a heat conduction cylinder 201 and a heating rod 202, and the heating rod 202 is arranged in the heat conduction cylinder 201; The propulsion assembly 302, the propulsion assembly 302 is fitted in the feed pipe 301, a...

Embodiment 2

[0053] refer to figure 1 with Figure 7 , is the second embodiment of the present invention, and this embodiment is different from the first embodiment in that: besides the furnace body 100, the heating unit 200 and the feeding unit 300, the calciner is also provided with a control unit 300, It includes a control box 401 outside the furnace body 100 and a monitoring component 402 inside the furnace body 100 , and the control box 401 is electrically connected to the heating rod 202 , the propulsion component 302 and the monitoring component 402 .

[0054] Monitoring components 402 are uniformly distributed on the side wall of the ring wall 101a of the calcining area A-1.

[0055] Compared with Example 1, further, in order to facilitate the temperature control of the calciner, a control box 401 for centralized control and problem solving is provided outside the calciner, and the control box 401 is electrically connected to the heating rod 202 and the propulsion assembly 302 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com