Color 3D printer

A 3D printer, color technology, used in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of high requirements for parts matching, difficult multi-color printing, inconvenient maintenance, etc., to facilitate maintenance and replacement, and avoid color mixing. Uniform, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

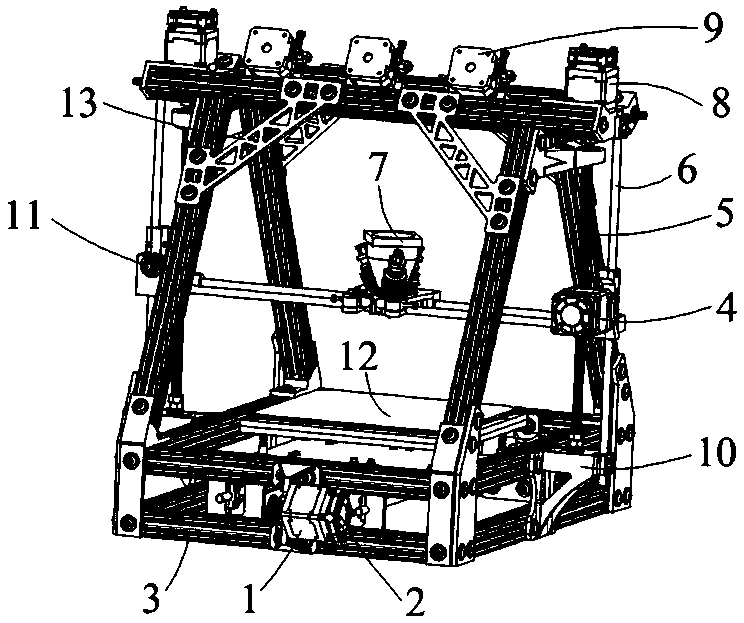

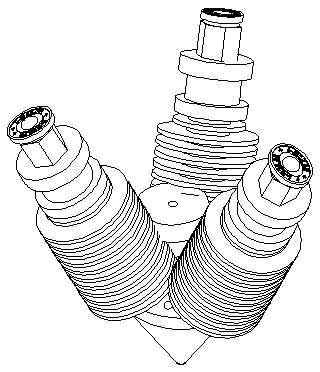

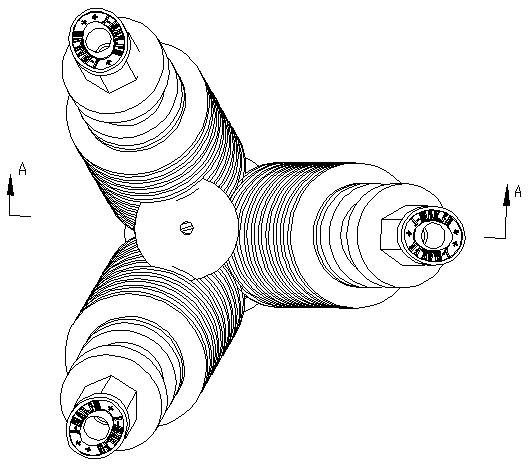

[0031] Embodiment 1: a kind of color 3D printer, see figure 1 and Figure 5 , including the nozzle, the frame, the tray installed on the frame, the X-axis moving mechanism and the Y-axis moving mechanism that control the movement of the tray; the frame is also equipped with the Z-axis moving mechanism that controls the movement of the nozzle, the X-axis moving mechanism, the Y The axis moving mechanism and the Z-axis moving mechanism constitute a Cartesian coordinate system.

[0032] The X-axis moving mechanism, the Y-axis moving mechanism, and the Z-axis moving mechanism each include a motor, a flange bearing, and a belt that transmits the power of the motor to the flange bearing. The belt is connected to the output end of the motor. The screw mandrel of the Y axis is connected with the flange bearing on the X-axis moving mechanism and the Y-axis moving mechanism to form a moving pair.

[0033] A slide bar corresponding to the Z-axis is provided on the frame, and a lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com