Controllable magnetic damping device for training machine

A training machine and magnetic damping technology, used in muscle training equipment, sports accessories, gymnastics equipment and other directions, can solve the problems of short service life, easy damage of magnetic damping devices, short service life of components, etc., and achieve good linear control characteristics, The effect of uniform resistance change and long service life

Inactive Publication Date: 2009-09-16

乔山健康科技(上海)有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, as long as it is a technology to adjust the distance between the magnetic adsorption part and the resistance wheel, the functional relationship between the moving distance of the magnetic adsorption part and the resistance received by the resistance wheel is an inverse square curve, see Figure 22 As shown in the above U.S. patents, the functional relationship between the resistance F of the resistance wheel and the distance S between it and the magnetic adsorption part is an inverse square curve, so that when the user is performing fitness activities, he can control and adjust the fitness equipment. The change of the resistance received is not uniform, stable, and linear, and there will be a bad feeling of steep rise and fall, which seriously affects the comfort of fitness equipment; in addition, because the inner or outer side of the resistance wheel is arc-shaped, the corresponding bracket The magnet group is also in the shape of an arc. To adjust the distance between the inner side of the resistance wheel of the arc shape and the magnet group of the arc shape to achieve a uniform change, a more complex structure and more parts are required. For example, the patent number is 5711404 , 6719107, 6345703 and other U.S. patents; so this type of magnetic damping device is easily damaged, has many faults, and has a short service life. For example, the steel cable of the reed will wear out after long-term use; the spring will lose part of its elasticity after long-term use. Therefore, the component life of the magnetic resistance technology of the traditional training machine is relatively short; also because this technology mostly uses complex force transmission components such as gears, cams, and torsion springs, it is not only easy to wear, but also the accuracy is affected; Some magnetic damping technologies cannot make the resistance of the resistance wheel change linearly, which brings inconvenience to the user (or designer) of the training machine for quantitative control and adjustment of the amount of exercise; and because the inner side of the resistance wheel and the magnet combination The distance between them is limited, this technology cannot completely disappear the magnetic field acting on the resistance wheel, so the variation range of its resistance is small and cannot be close to zero

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0089] 1) nickel-iron alloy containing 48%---50% nickel;

[0090] 2) nickel-iron alloy containing 72%---83% nickel;

[0091] 3) 80% nickel, molybdenum 4.15%----5.15%, iron 14.85%----15.85%;

[0092] 4) Ultra-low carbon steel, also known as pure iron. Pure iron with a carbon content of less than 0.008% is preferred as the shielding material, which has the advantage of low cost.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

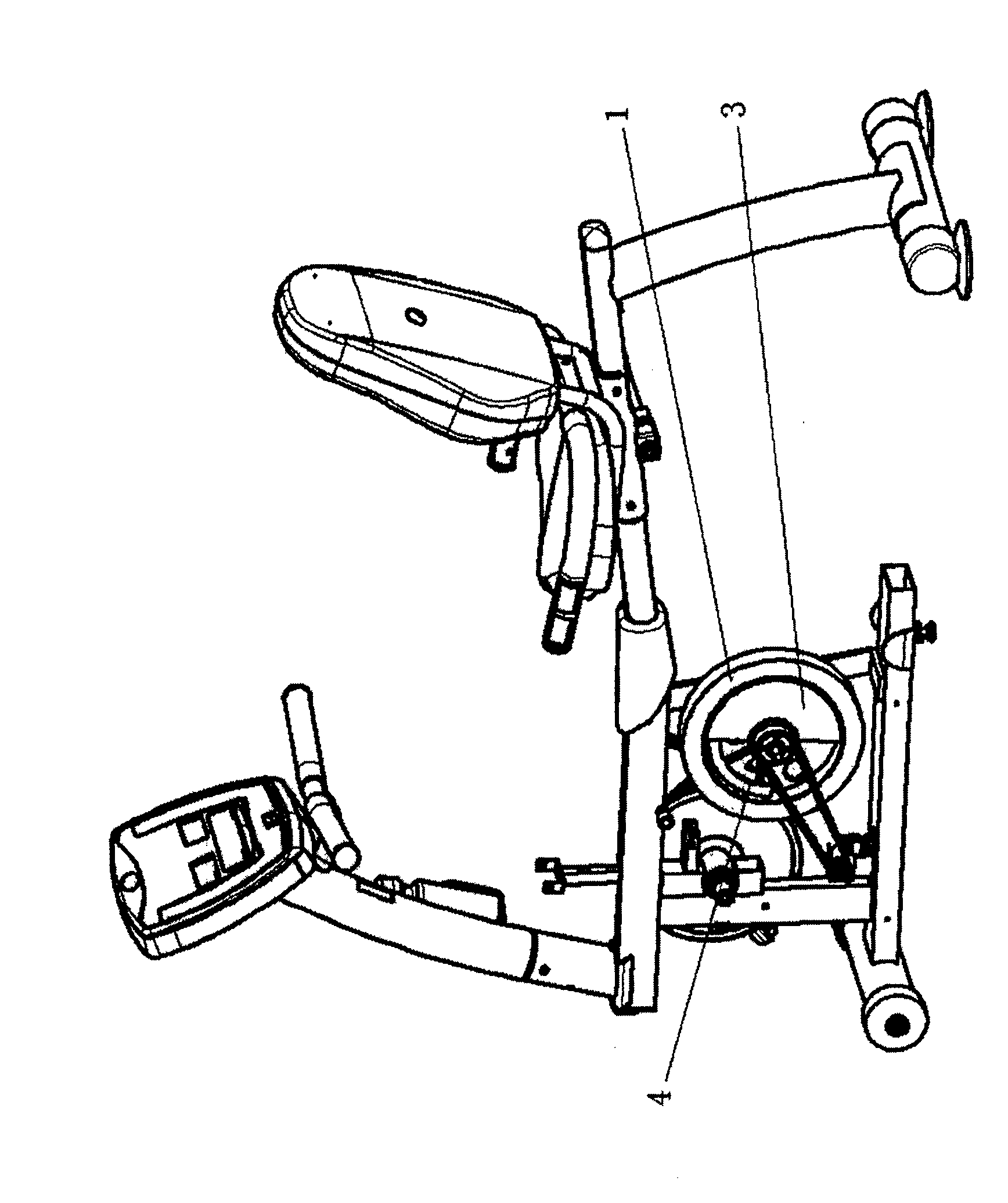

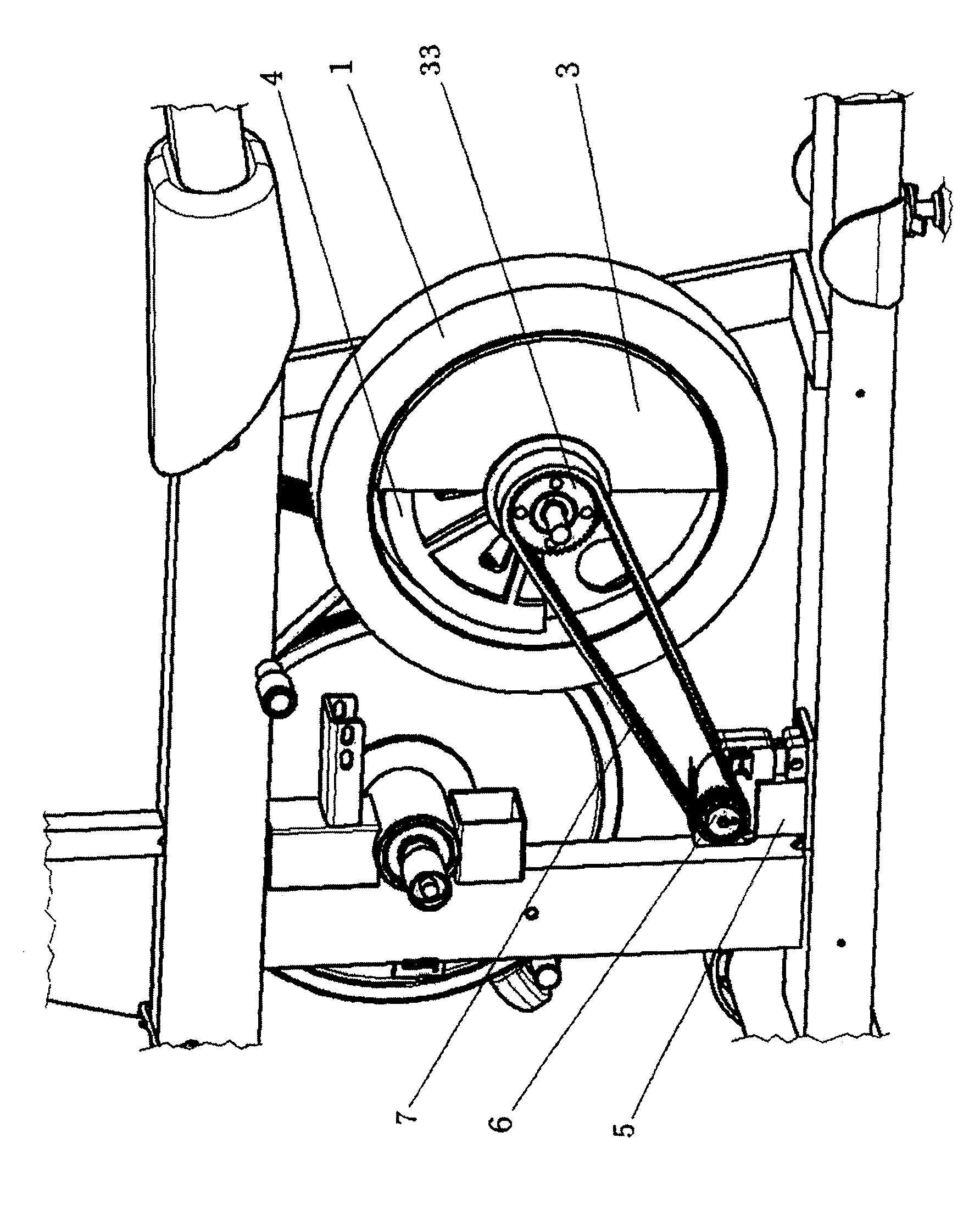

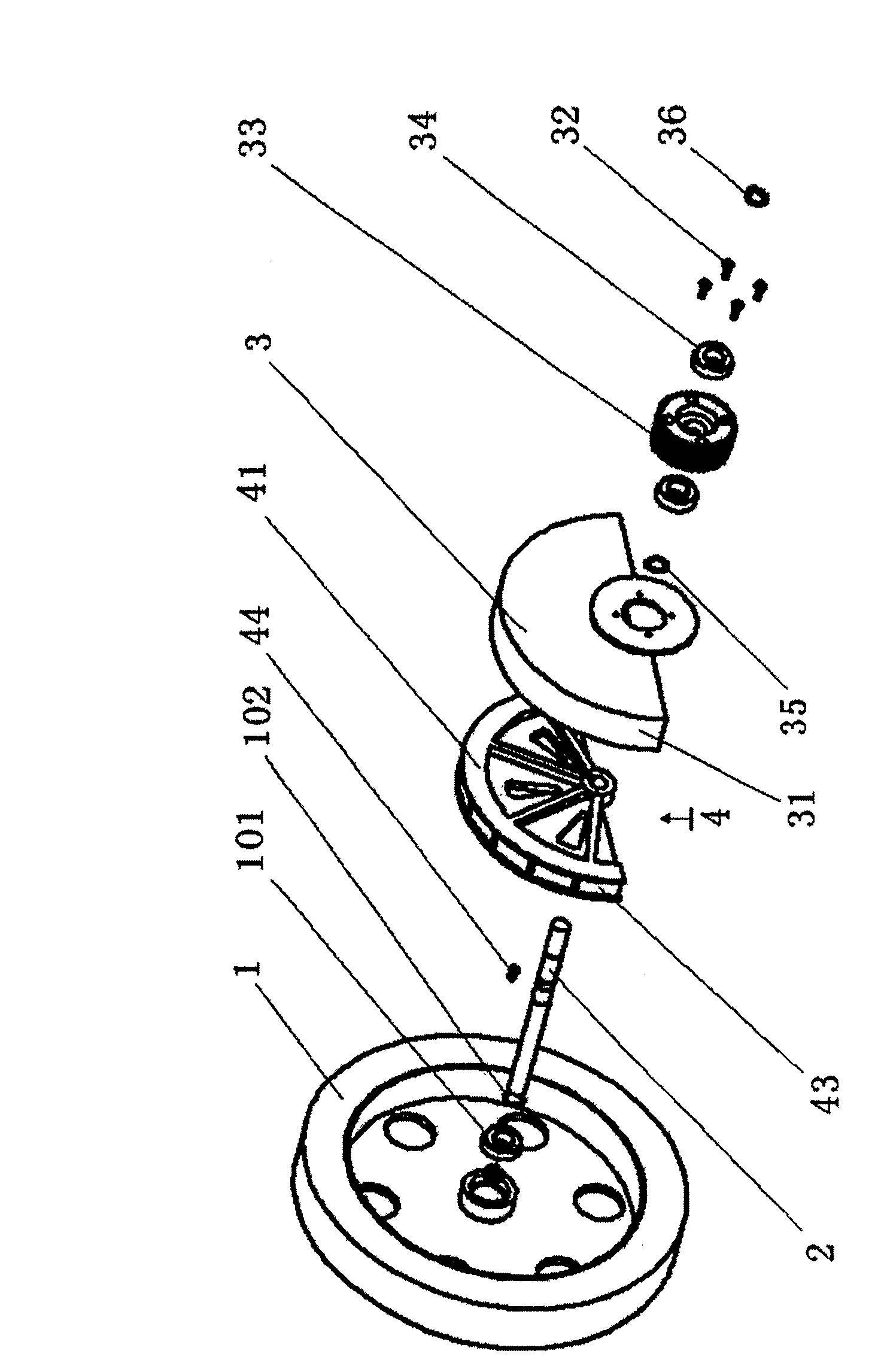

Login to View More Abstract

The invention discloses a controllable magnetic damping device for a training machine, comprising: a resistance wheel pivotally arranged on a fixed shaft of the training machine; a magnetic force component including: a magnetic material frame set on the resistance wheel Beside, a gap is formed between the magnetic material frame and the resistance wheel; several magnetic adsorption parts are arranged on the magnetic material frame; the feature is that: the controllable magnetic damping device further includes a shielding cover, which is equipped with A shielding plate that can pass through the gap between the magnetic component and the resistance wheel; at least one of the shield cover and the magnetic material frame can be adjusted and positioned by the user, and the gap between the magnetic adsorption part of the magnetic component and the resistance wheel can be changed. The magnetic line of force passes through the area, and then adjusts the size of the resistance suffered by the resistance wheel. The controllable magnetic damping device of the training machine of the present invention has the characteristics of few parts, simple structure, long service life, uniform, stable and convenient adjustment, and can linearly adjust and control resistance from zero to maximum.

Description

technical field [0001] The invention belongs to the technical field of fitness equipment, and in particular relates to a controllable magnetic damping technology of a resistance wheel of a training machine. Background technique [0002] The magnetic damping technology of traditional training machines basically adopts the method of adjusting the distance between the magnetic adsorption part (magnet) and the resistance wheel to change the resistance of the resistance wheel, such as the US patents with patent numbers 5711404, 6719107, 6345703, 6273845, etc.; , the resistance of a conductor moving in a magnetic field is related to the strength of the magnetic field, and the strength of the magnetic field is inversely proportional to the square of the distance between the conductor and the magnet. Therefore, the magnetic induction intensity is inversely proportional to the square of the distance, so according to the Ampere force formula F=BIL, it can be known that the electromagn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A63B21/22A63B21/005

Inventor 冯建军

Owner 乔山健康科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com