Carbon crystal heating electric heating painting

A carbon crystal and electric heating technology, applied in the field of electric heating, can solve the problems of fire, high heating temperature, fast heating speed, etc., and achieve the effect of avoiding damage to the heating plate or fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

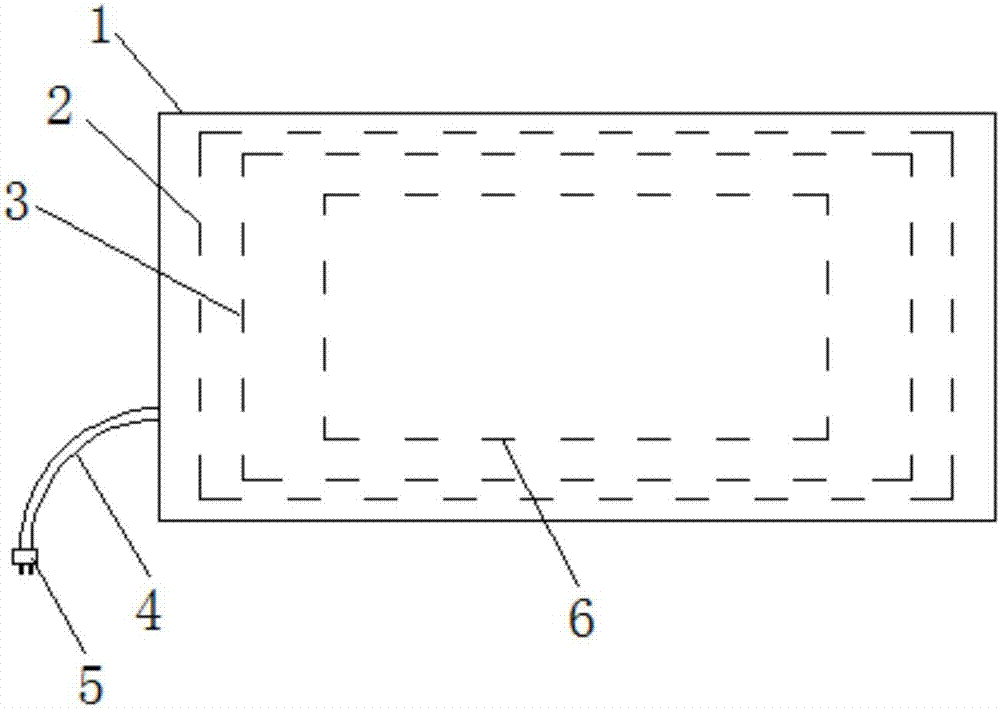

[0029] figure 1 A schematic diagram of a carbon crystal heating electric heater according to an embodiment of the present invention is shown.

[0030] Such as figure 1 As shown, the present invention provides a carbon crystal heating electric heating picture, which includes: a housing 1, a panel layer is provided on one side of the housing 1, and a shielding plate 2 is provided on the other side; a carbon crystal heating plate 6, The carbon crystal heating plate 6 is located inside the housing 1, and the carbon crystal heating plate 6 is respectively provided with a first thermal insulation layer 3 and a second thermal insulation layer ( figure 1 , the second insulation layer overlaps with the first insulation layer), the charging unit is electrically connected to the carbon crystal heating plate 6, and is placed outside the casing 1 through the side of the casing 1, and the overheating protection unit Set on the charging unit; a monitoring unit, the monitoring unit is set i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com