Graphene heating brick circuit structure

An olefin heating brick and circuit structure technology, applied in ohmic resistance electrodes, heating element materials, ohmic resistance heating components, etc., can solve problems such as being unsafe, unable to meet demand, and cost a lot of electricity, to ensure safety and effectiveness. The effect of controlling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings.

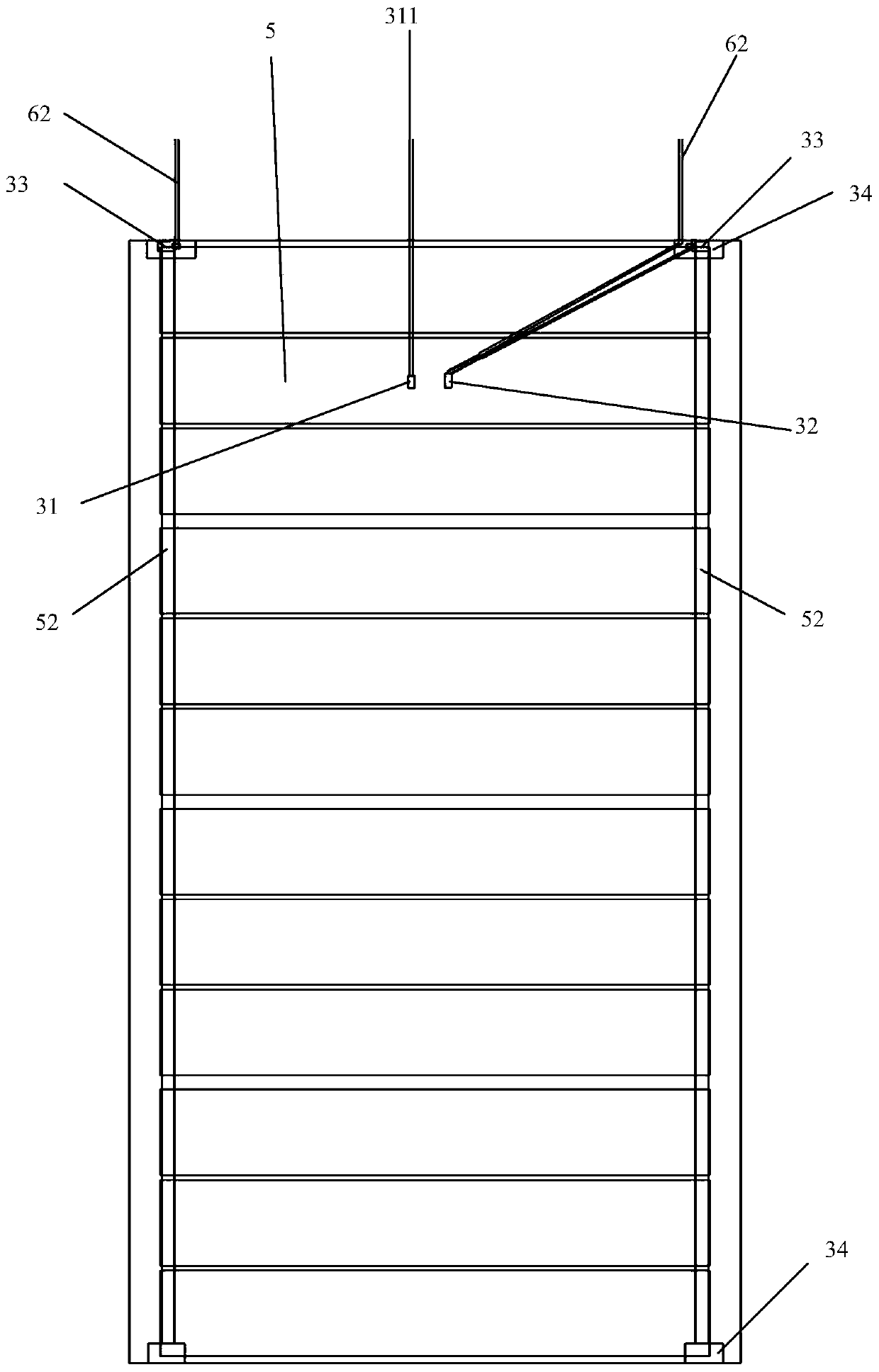

[0024] Such as figure 2 As shown, the circuit structure of a graphene heating brick includes a graphene heating brick 2 and an intelligent temperature controller 4 electrically connected to the graphene heating brick. The intelligent temperature controller 4 heats the graphene heating tile, and when the set temperature is reached, the intelligent temperature control The device 4 will disconnect the power supply and reach a constant temperature to generate heat.

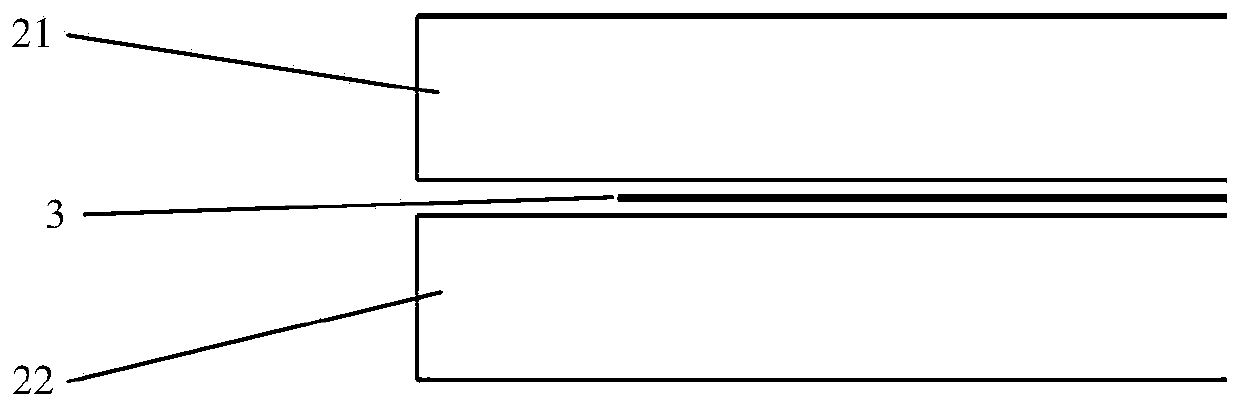

[0025] The graphene heating tile 2 includes a tile layer 21, a graphene heating chip layer 3 and a heat preservation layer 22 glued together from top to bottom.

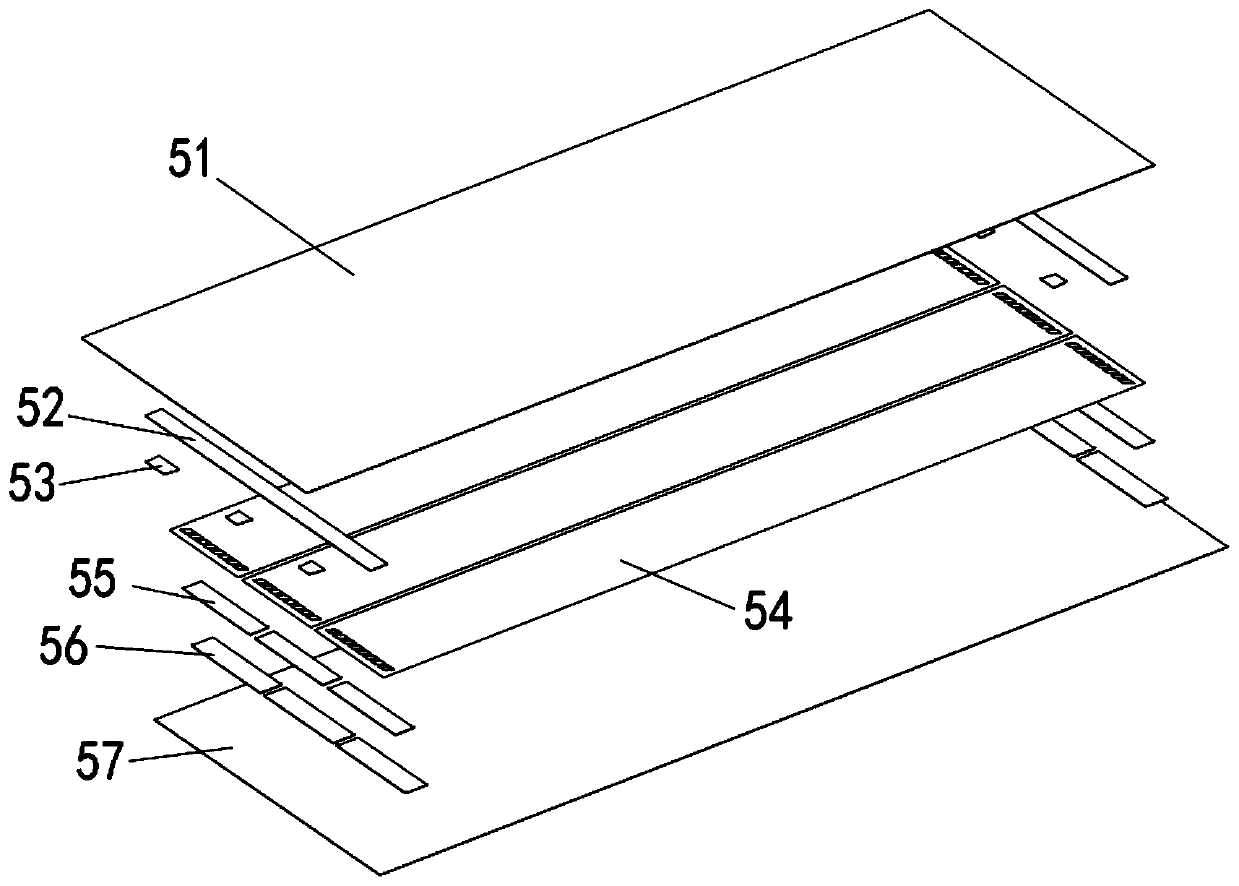

[0026] Such as image 3 As shown, the graphene heating chip layer 3 includes a graphene heating film 5. Two ends of the graphene heating film 5 are provided with heating film current-carrying electrodes 52 respectively, and the heating film current-carrying e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com