High-temperature-resistant gas sensor and packaging method thereof

A gas sensor and high-temperature-resistant technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of deterioration, easy melting, and poor sealing of sensors, and achieve high temperature resistance, low cost, and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

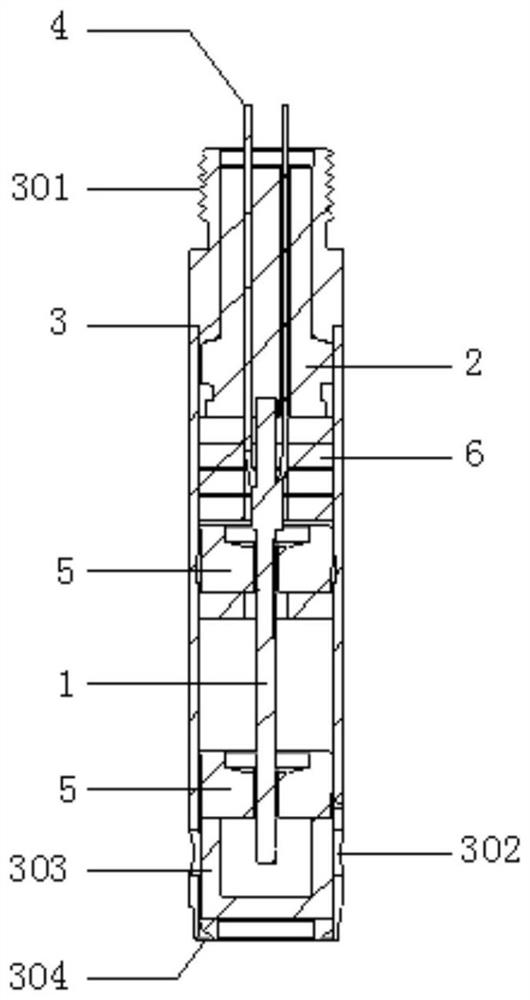

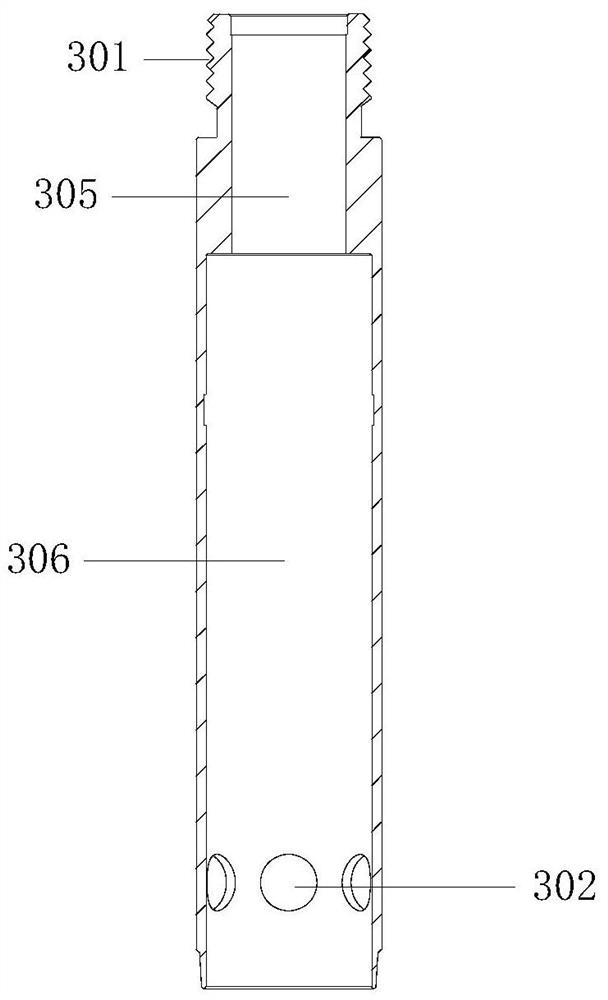

[0042] This embodiment provides a high temperature resistant gas sensor, such as Figure 1 to Figure 5 As shown, it includes a sensor element 1 and a casing 3. The sensor element 1 is placed in the casing 3. The sensor element 1 includes a detection end and an electrode end. The detection end of the sensor element 1 is used for gas detection. The extreme end is connected with a wire 4, and the inside of the sleeve 3 is provided with a first cavity 305 and a second cavity 306, and a lead device 2 is fixed in the first cavity 305, and the electrode end of the sensor element 1 and the lead device 2 Butt connection, the wire 4 connected to the electrode end is drawn out from the lead wire device 2, the second cavity 306 is used to place the sensor original 1, and a ceramic cake 6 and a ceramic pressure ring 5 are also arranged in the second cavity 306, the said The ceramic cake 6 fixes the electrode end of the sensor element 1 in the second cavity 306 , and the ceramic pressure ri...

Embodiment 2

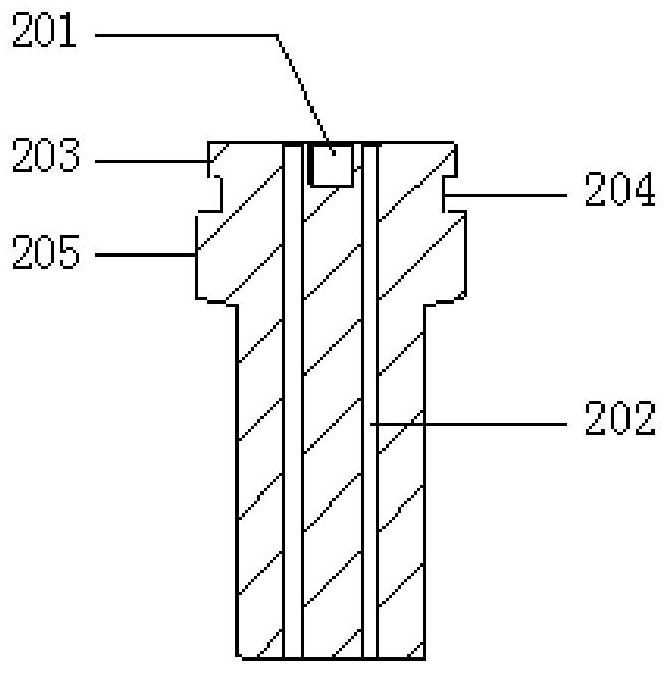

[0045] As an optimization to the above-mentioned embodiment, the lead wire device 2 is a cylinder, and a limit groove 201 is provided at the position where it abuts with the electrode end of the sensor element 1, and the electrode end of the sensor element 1 is fixed in the limit groove 201, and the lead wire device 2 A wire passing hole 202 runs through the inside of the wire along the axial direction, and the wire 4 is drawn out from the wire passing hole 202 . The size of the limiting groove 201 can be slightly larger than the electrode end of the sensor element 1, so that the end of the electrode end of the sensor element 1 is just placed in the limiting groove 201; the wire passing hole 202 is arranged on both sides of the limiting groove 201 Or around, its aperture is slightly larger than the diameter of the wire 4, and the number of wire passing holes 202 is the same as the number of electrodes of the sensor element 1. For ease of use, 6 wire passing holes 202 can be arr...

Embodiment 3

[0048] As an optimization of the above example, such as Figure 6 to Figure 7 As shown, the casing 3 is provided with a vent hole 302 on the outer wall of the end at one end of the second cavity 306, and a gas filter 303 is provided at the end of the second cavity 306 at the detection end of the sensor element 1 to filter the gas. The device 303 is a cup-shaped body with its open end facing the detection end of the sensor element 1 , covering the detection end of the sensor element 1 in the second cavity 306 , and the air hole 302 on the casing 3 facing the gas filter 303 . A sealing device 304 is provided outside the gas filtering device 303 , and the sealing device 304 fixes the gas filtering device 303 at the end of the second cavity 306 . The ceramic pressure ring 5 is provided with two, one of which presses and fixes the ceramic cake 6 on the electrode end of the sensor original 1, and the other is located in the second cavity 306 near the end of the sensor original 1 det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com