Slow tensile test method of pipeline steel in hydrogen environment

A tensile test and pipeline steel technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Safety and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A specific embodiment of the present invention provides a slow tensile test method for pipeline steel in a hydrogen environment, using the slow tensile test device for pipeline steel in a hydrogen environment in Example 1 to perform a slow tensile test, including the following step:

[0060] Step S1: Install the pipeline steel 7 of the test sample into the hydrogen environment box;

[0061] Step S2: filling the pipeline steel 7 in the hydrogen environment box with hydrogen;

[0062] Step S3: Connect the hydrogen-charged pipeline steel 7 to a slow stretching apparatus to perform a slow stretching test.

[0063] In a specific embodiment of the present invention, in step S1, the installation process of pipeline steel 7 includes:

[0064] Step S11: Open the hydrogen environment box and put in the pipeline steel 7 to be tested;

[0065] Step S12: passing one end of the pipeline steel 7 through the sealing cover 2, and the other end through the bottom of the box body 1;

...

Embodiment 2

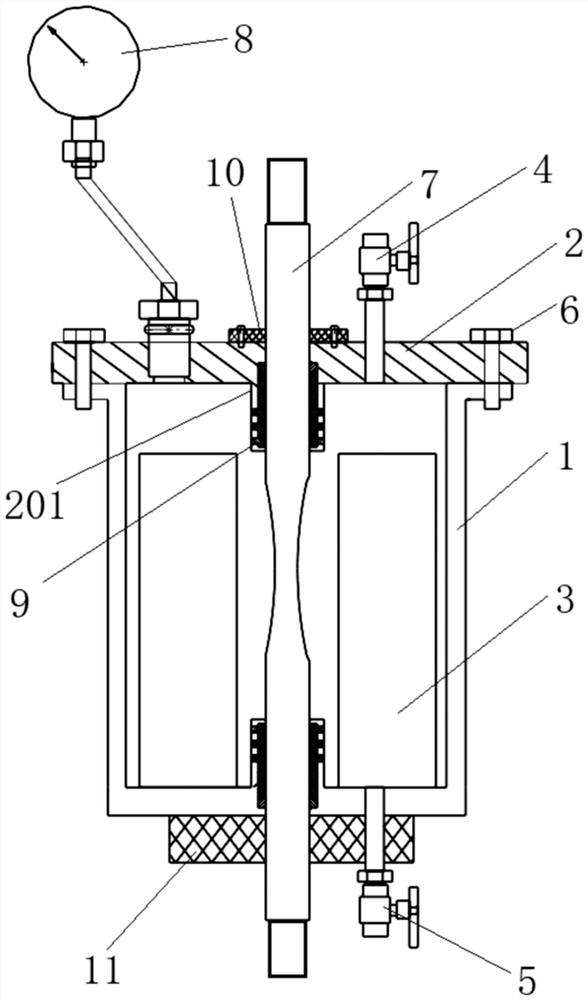

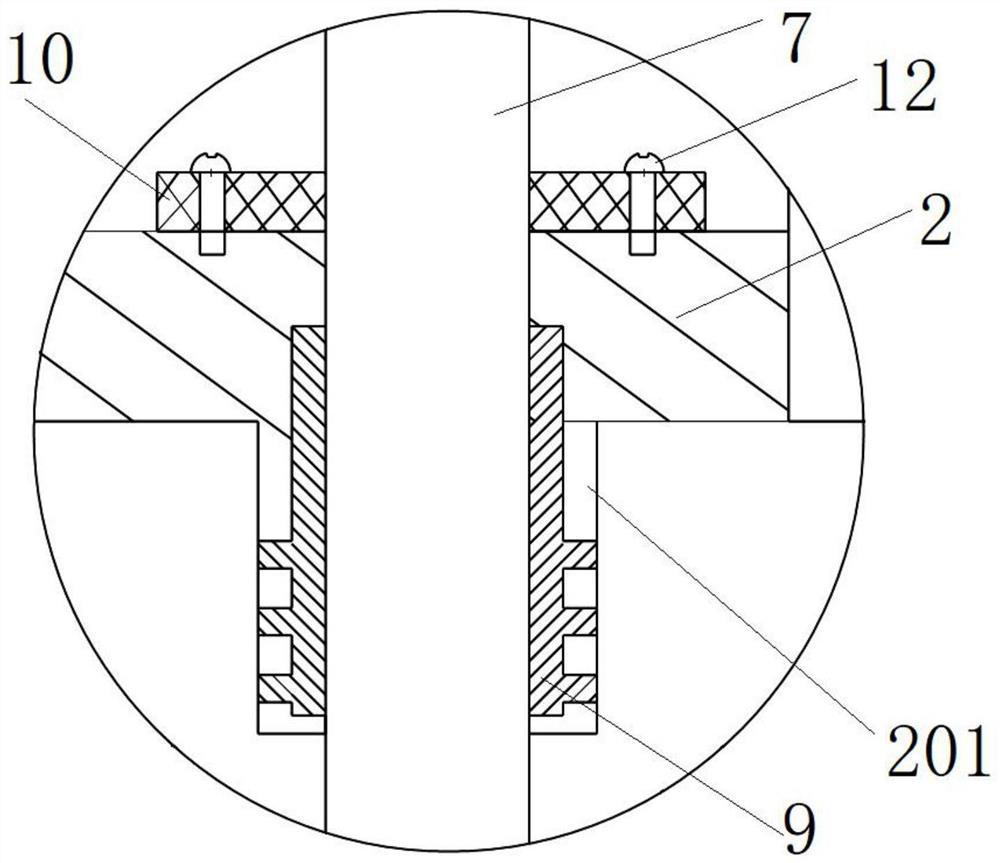

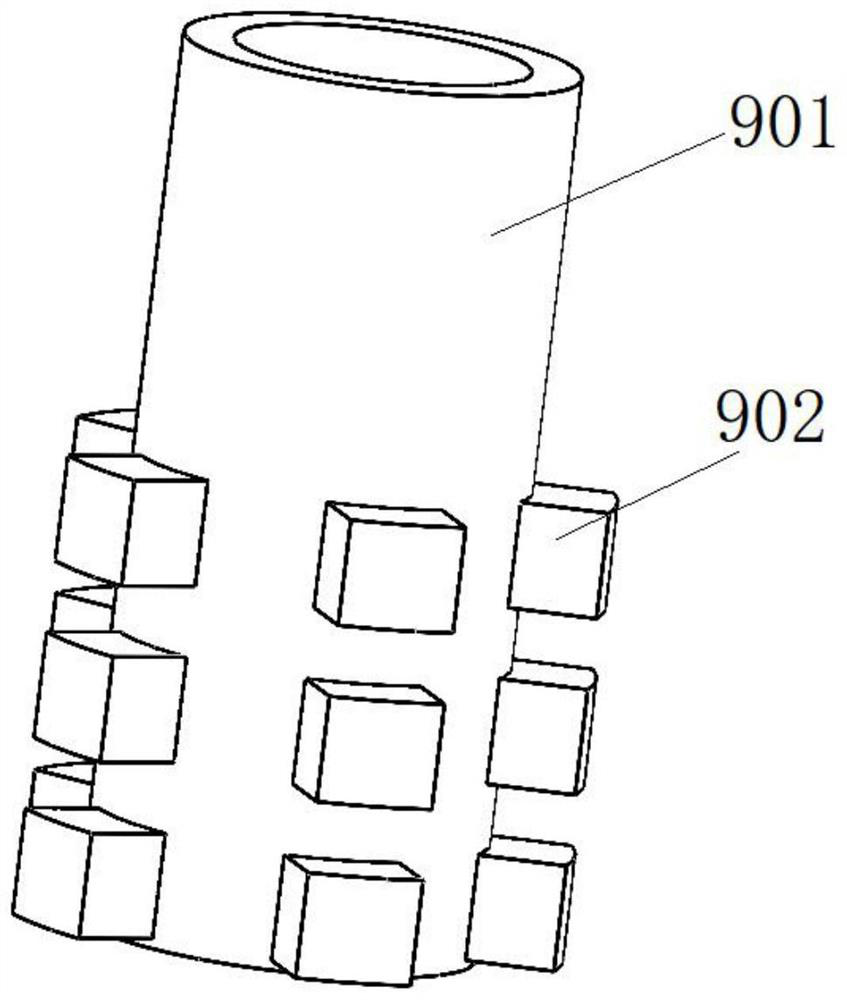

[0081] A specific embodiment of the present invention discloses a slow tensile test device for pipeline steel in a hydrogen environment, such as Figure 1-Figure 8 As shown, it is used to realize the slow tensile test method in Example 1; the slow tensile test device of the pipeline steel in a hydrogen environment includes: a slow tensile instrument and a hydrogen environment box.

[0082] Among them, the hydrogen environment box is used to simulate the hydrogen pressure environment; the slow tensile test metal sample is placed, that is, the pipeline steel 7 is placed in the hydrogen environment box; Stretch pipeline steel 7. The slow stretching instrument is an instrument for slow stretching test, which is an existing product, and will not be described in detail in the present invention.

[0083] Further, the air inlet pipe 4 is used for introducing gas into the hydrogen environment box.

[0084] Further, the gas outlet pipe 5 is used to discharge the gas out of the hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com