Large-tonnage foundation pile uplift-resistant static test connection device, loading counter-force system and method

A technology of static load test and connection device, which is applied in the test of foundation structure, foundation structure engineering, construction, etc. It can solve the problems of destroying the integrity of pipe piles, uneven stress on longitudinal reinforcement, and harsh site conditions, so as to avoid The effect of uneven stress on longitudinal reinforcement, improving the quality of engineering piles, and reducing engineering hidden dangers

Active Publication Date: 2013-03-27

广东省建设工程质量安全检测总站有限公司

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Specifically, due to the limitation of the distance of 3-4d (d is the diameter of the tested pile) between the reaction support and the test pile, the traditional beam reaction device puts forward higher requirements on the loading equipment such as steel beams, and The site conditions are harsh, so the bearing capacity of most engineering piles is only determined by the existing test data or the experience of the designer, so there are certain engineering hidden dangers

Also, for example, the reasonable size of the loading device: the transportation and hoisting of large-volume loading beams are expensive, and there are many difficulties if on-site splicing is used; and the loading reaction force of small-volume loading beams will have a negative impact on the test results of test pipe piles. greater impact, and there are potential safety hazards during the test

However, the defects of these two loading reaction devices are: (1) the main beam is located above the test pipe pile, and the longitudinal reinforcement on the pipe pile directly below the main beam needs to be bent outward before welding the steel bar. During the load test, there will be uneven stress on the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

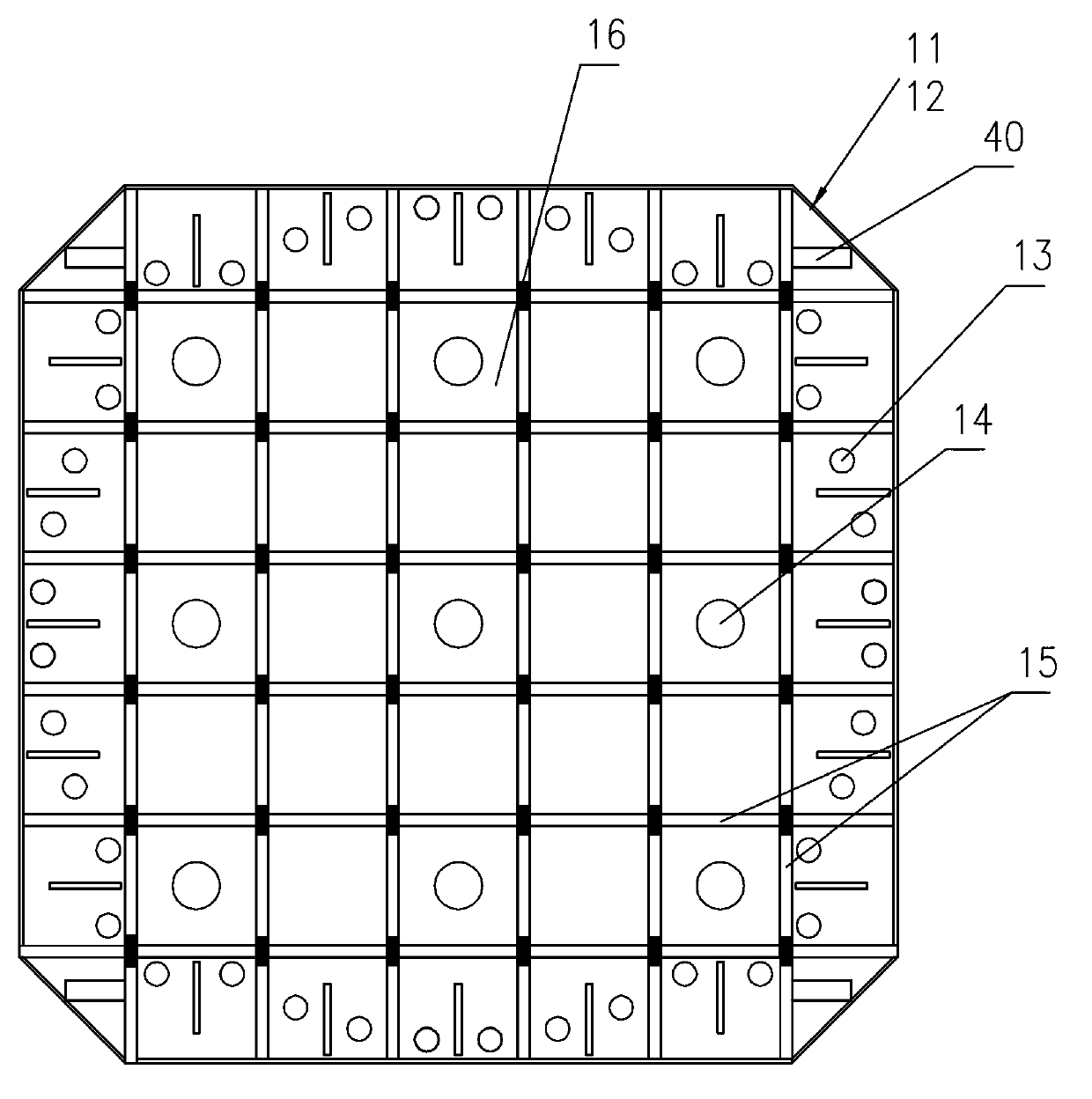

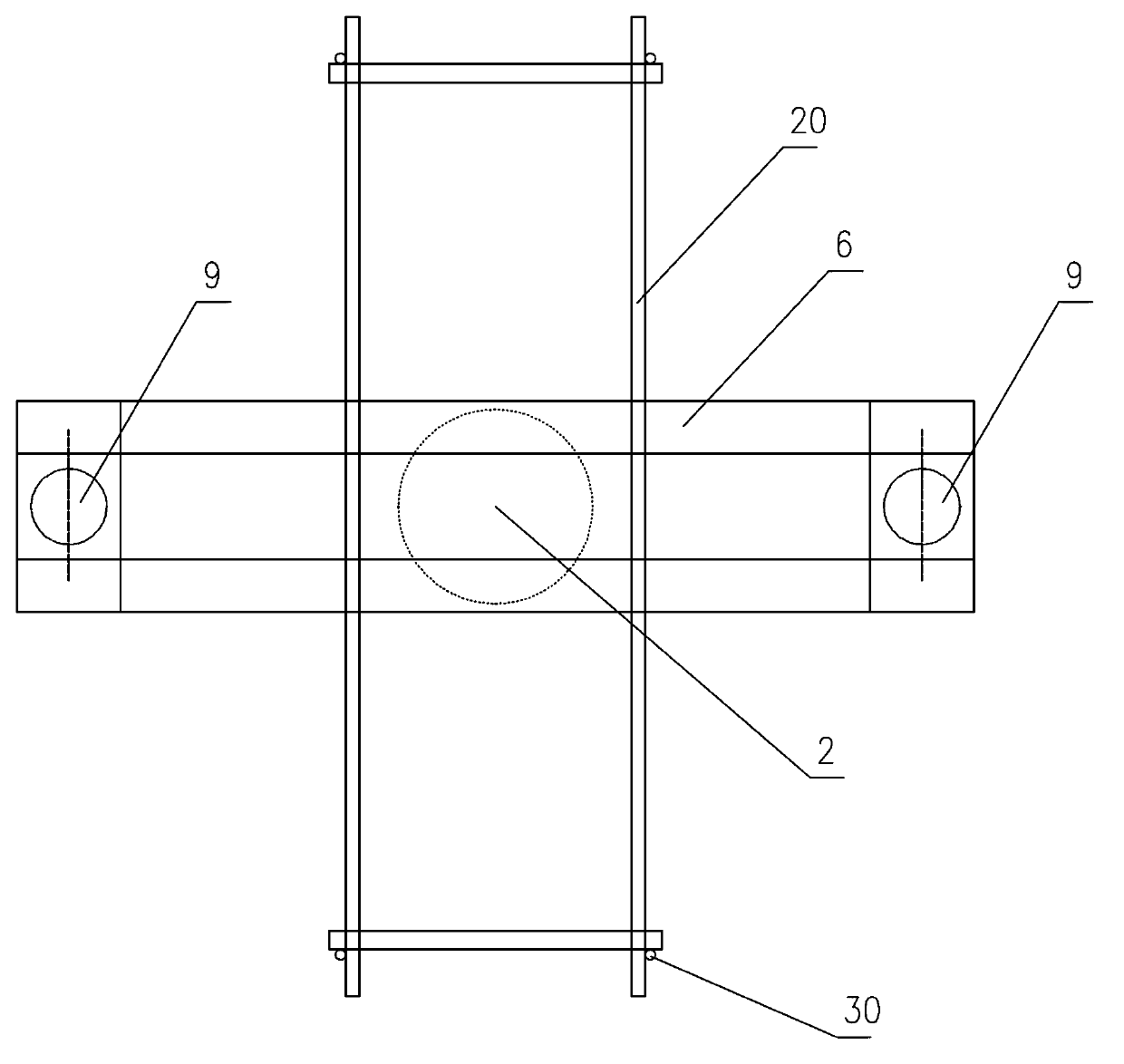

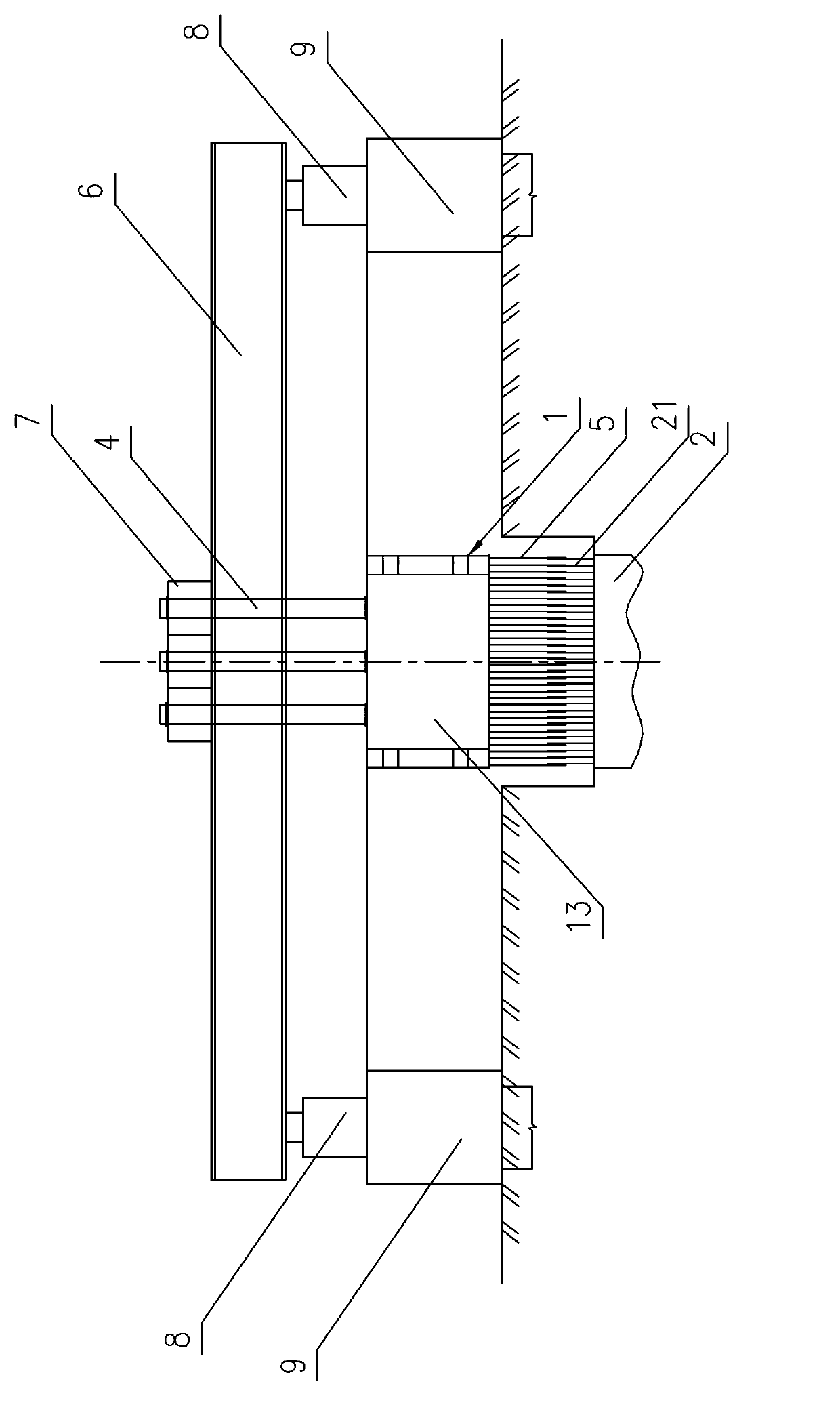

The invention discloses a large-tonnage foundation pile uplift-resistant static test connection device. The large-tonnage foundation pile uplift-resistant static test connection device mainly comprises a cubic hollow shell, a lower connection rod connected with a longitudinal rib on an uplift-resistant tube pile to be detected, and an upper connection rod connected with a loading counter-force device. The lower connection rod is vertically arranged on the bottom surface of the shell; the position of the lower connection rod is opposite to the position of the longitudinal rib on the uplift-resistant tube pile to be detected in the up-down direction; and the upper connection rod is vertically arranged on the top surface of the shell. The invention also discloses the loading counter-force system which consists of the test connection devices, and a testing method thereof. According to the large-tonnage foundation pile uplift-resistant static test connection device, the loading counter-force system and the testing method, the vertical connection between the longitudinal rib on the uplift-resistant tube pile and the lower connection rod is basically realized, the uniform stress phenomenon of the longitudinal bar is avoided, the accuracy of test results is ensured, and the completeness of the tube pile is also guaranteed. The device can be repeatedly used, so that the quality of engineering piles is improved, the engineering hidden trouble is reduced, and the device is suitable for uplift-resistant static tests of the foundation piles with the pile diameter of 2m and the test load of about 20,000kN.

Description

technical field [0001] The invention belongs to the technical field of pile foundation detection in construction engineering, and in particular relates to a large-tonnage foundation pile anti-lifting static load test connection device, a loading reaction system composed of the above-mentioned test connection device, and a test method for the system. Background technique [0002] With the development of economic construction, large buildings have higher and higher requirements for the uplift bearing capacity of pile foundations, so it is necessary to carry out static load tests on pile foundations with large tonnage. [0003] In the static load test of large-tonnage foundation piles, the loading reaction device involves two problems, one is how to realize the reaction force; the other is how to solve the negative effect of the reaction force. Strict requirements for test loading devices and implementation methods of loading reaction force in large-tonnage pile foundation stat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D33/00

Inventor 李广平李超华杨眉吴伟衡徐天平毛良基孙志贤庞忠华王首添谢永桥李浩年陈丽丽

Owner 广东省建设工程质量安全检测总站有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com