Strip-mode laser scanning path planning method

A technology of laser scanning path and scanning path, which is applied in the field of additive manufacturing, can solve the problem of continuous opening and closing of lasers, and achieve the effect of ensuring the forming quality, improving the quality of parts, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Combine below Attached drawing The present invention will be described in detail with specific embodiments.

[0019] The present invention is a strip-type laser scanning path planning method, which merges the too short path in each strip zone of the single-layer section of a part with the scanning path in the adjacent zone and the scanning path located on the same path, wherein, in each strip zone The adjacent scanning path directions of are the same or opposite; the specific implementation steps are as follows:

[0020] Step 1: Input the slice files of each layer of the part 3D model, divide each layer of the part into strips according to the structural characteristics of the part, and plan the parallel line scan path for each strip zone;

[0021] Step 2: Read in the user-defined shortest path length and record it as L, where L is less than or equal to the width of a single strip area

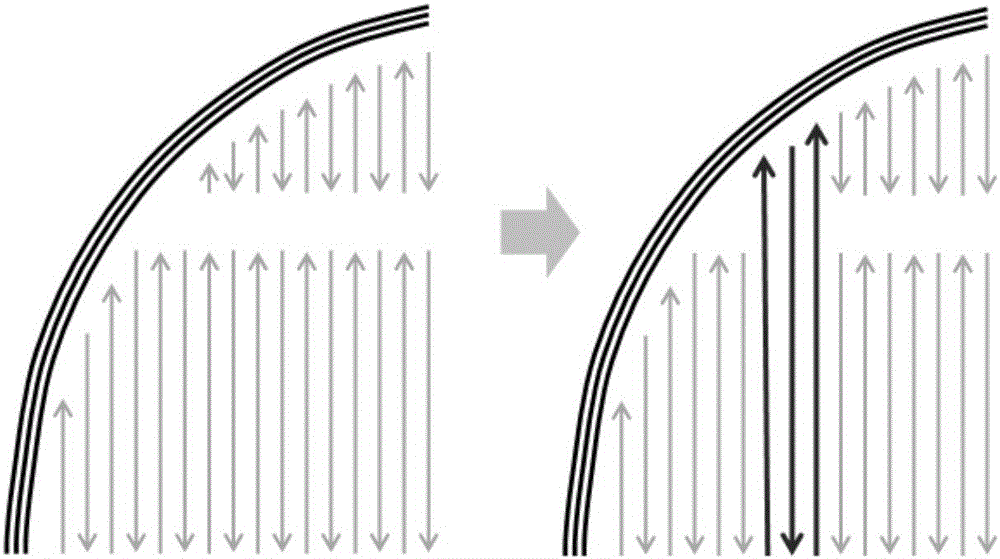

[0022] Such as figure 1 As shown, step 3: Using L in step 2 as the reference, starting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com